Layer combustion compound ventilation chain discontinuous running type coal boiler

A composite ventilation and chain technology, applied in the field of hot water heating boilers, can solve problems such as affecting safe and stable operation and thermal efficiency, poor layout of heating surfaces, reducing thermal efficiency, etc., to eliminate boiler air leakage, save maintenance and replacement costs, and comprehensive energy efficiency. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

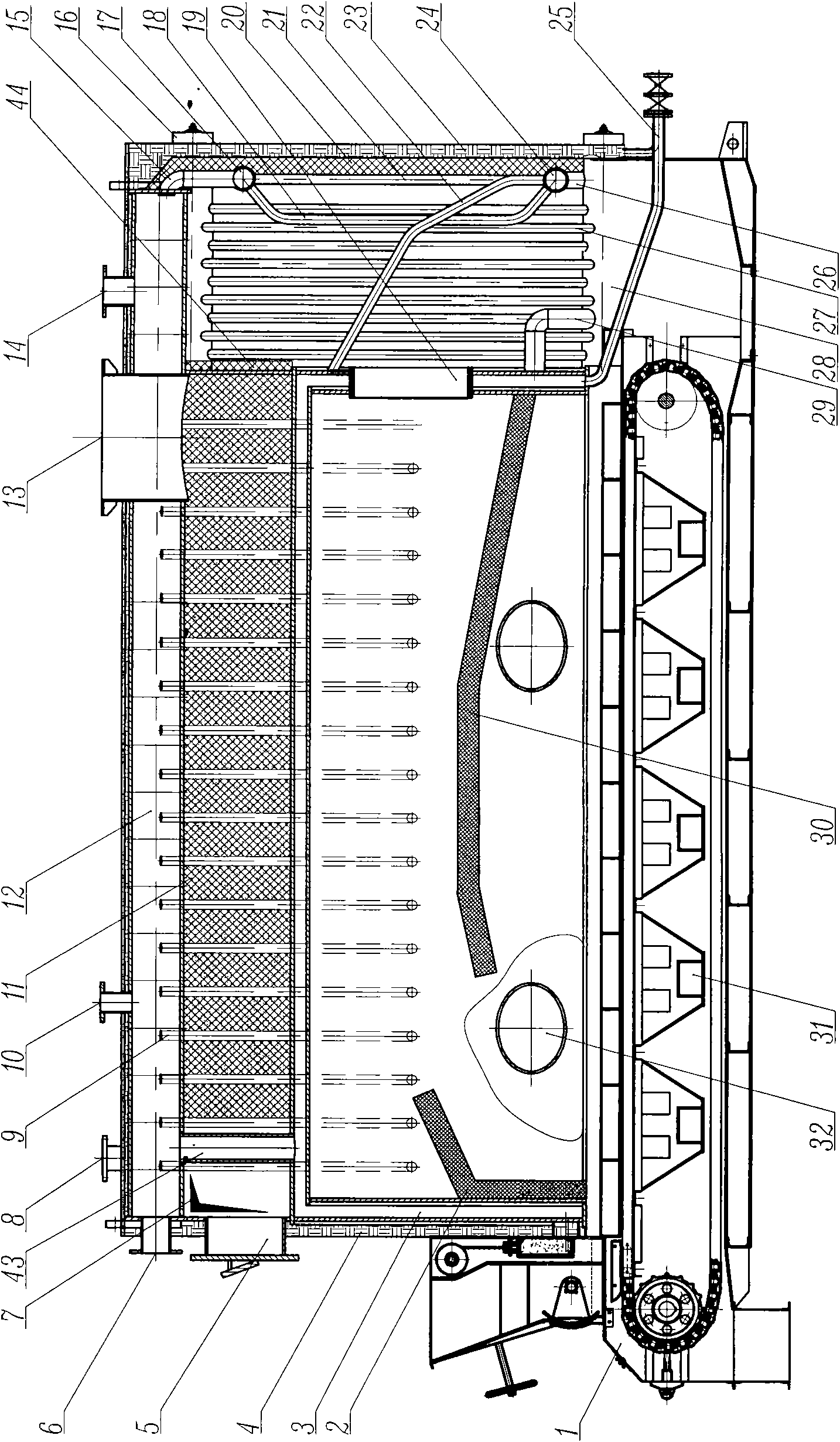

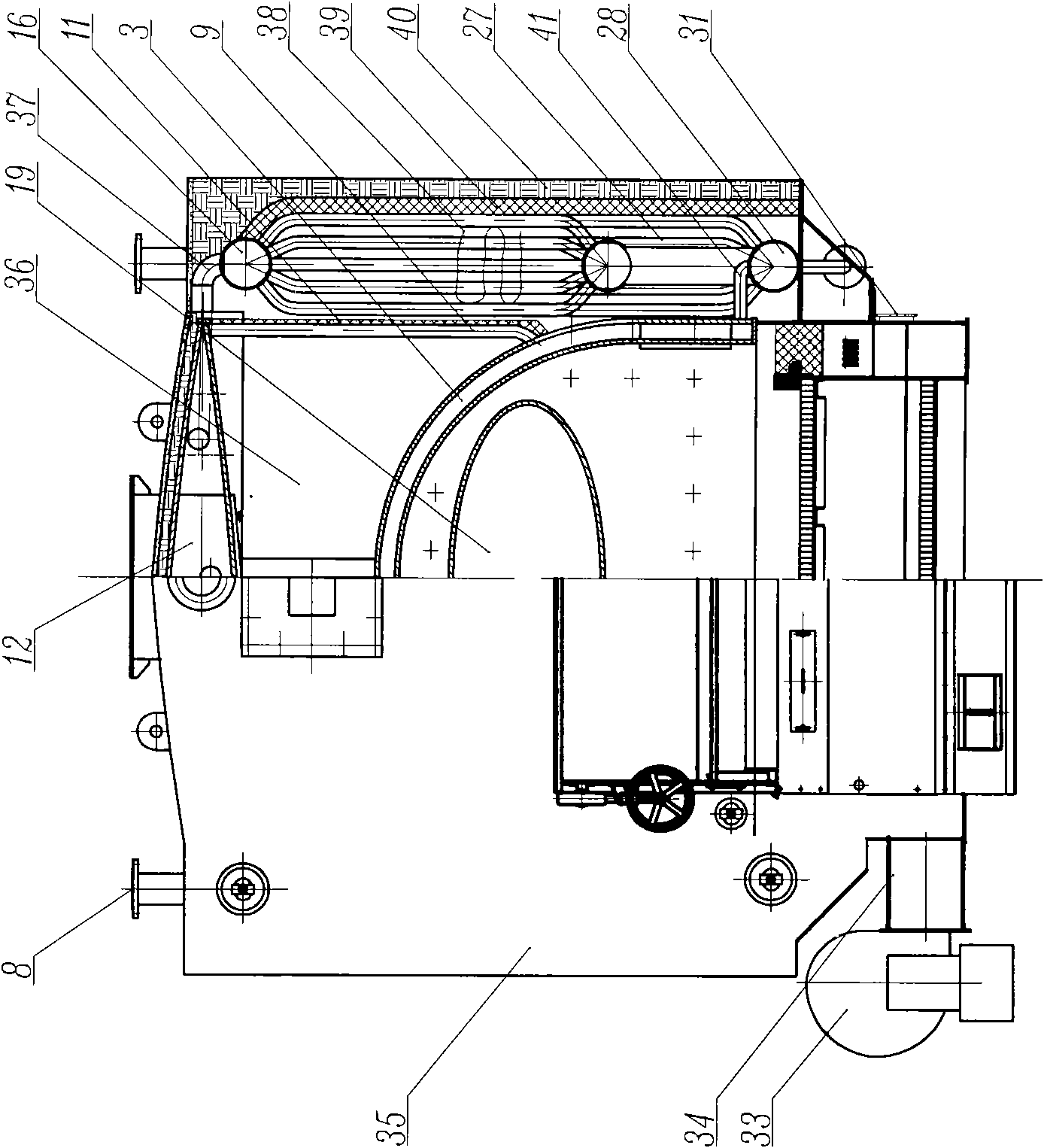

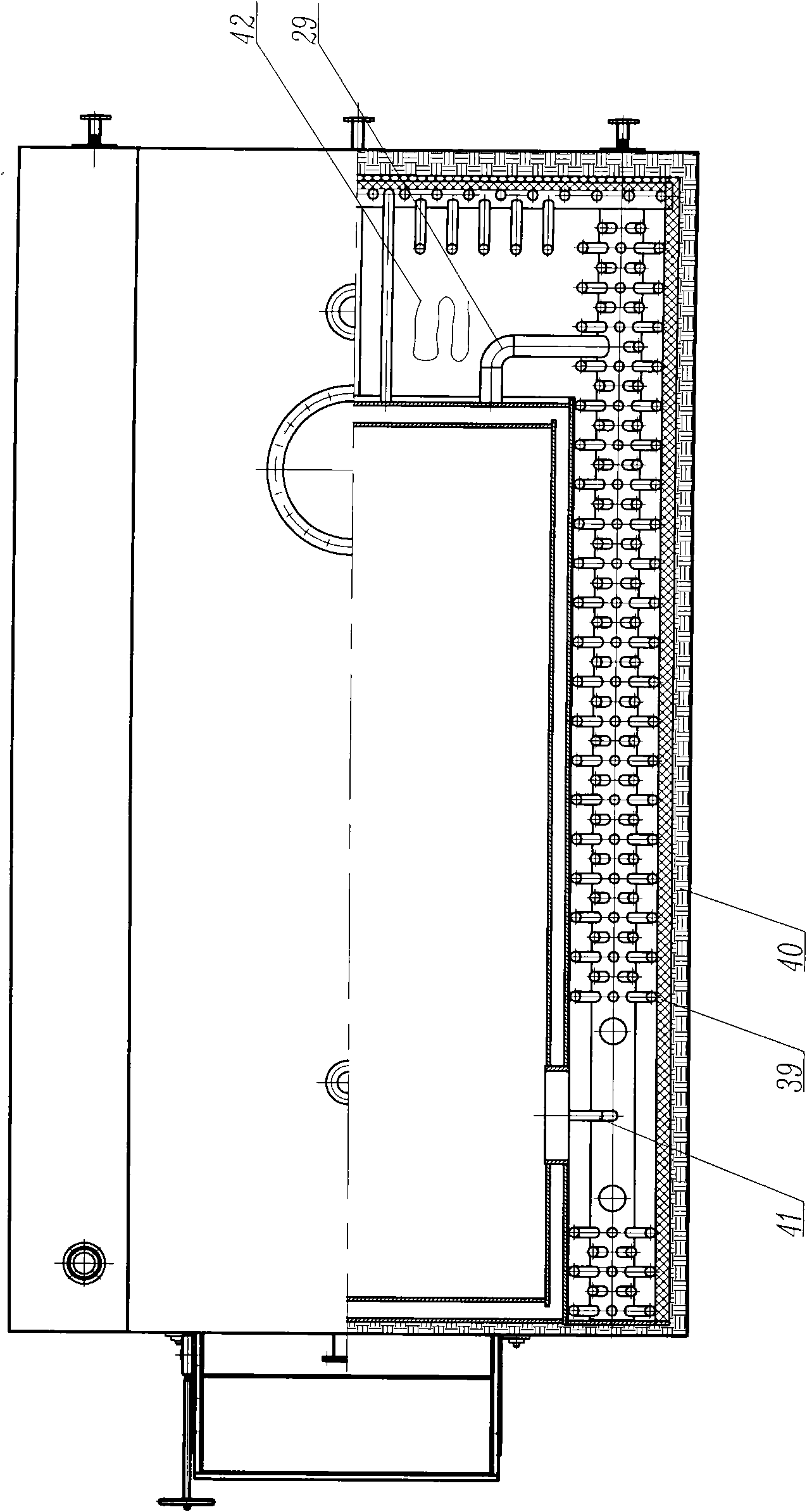

[0019] Below in conjunction with accompanying drawing, the present invention will be described in detail, a kind of layer combustion composite ventilating chain intermittently operated briquette boiler, by arched water jacket (3), ellipse water jacket (12), side upper and lower header (16), ( 28), convection tube bundle (27) etc. are formed, it is characterized in that, connecting tube (43) (29) (37) (26) (15), wall tube (9) and arched water jacket (3), oval water jacket respectively Cover (12), side upper and lower headers (16) (28) are connected, and the center of the front end of the ellipse water jacket (12) is installed according to the water outlet (6), and the rear upper part passes through the upper and lower walls according to the installation. Cigarette outlet (13), its longitudinal center rear part and front part pass through the upper wall and press the air inlet (14), the medicine feeding port (10), and the front upper part of the header box (16) on the side is pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com