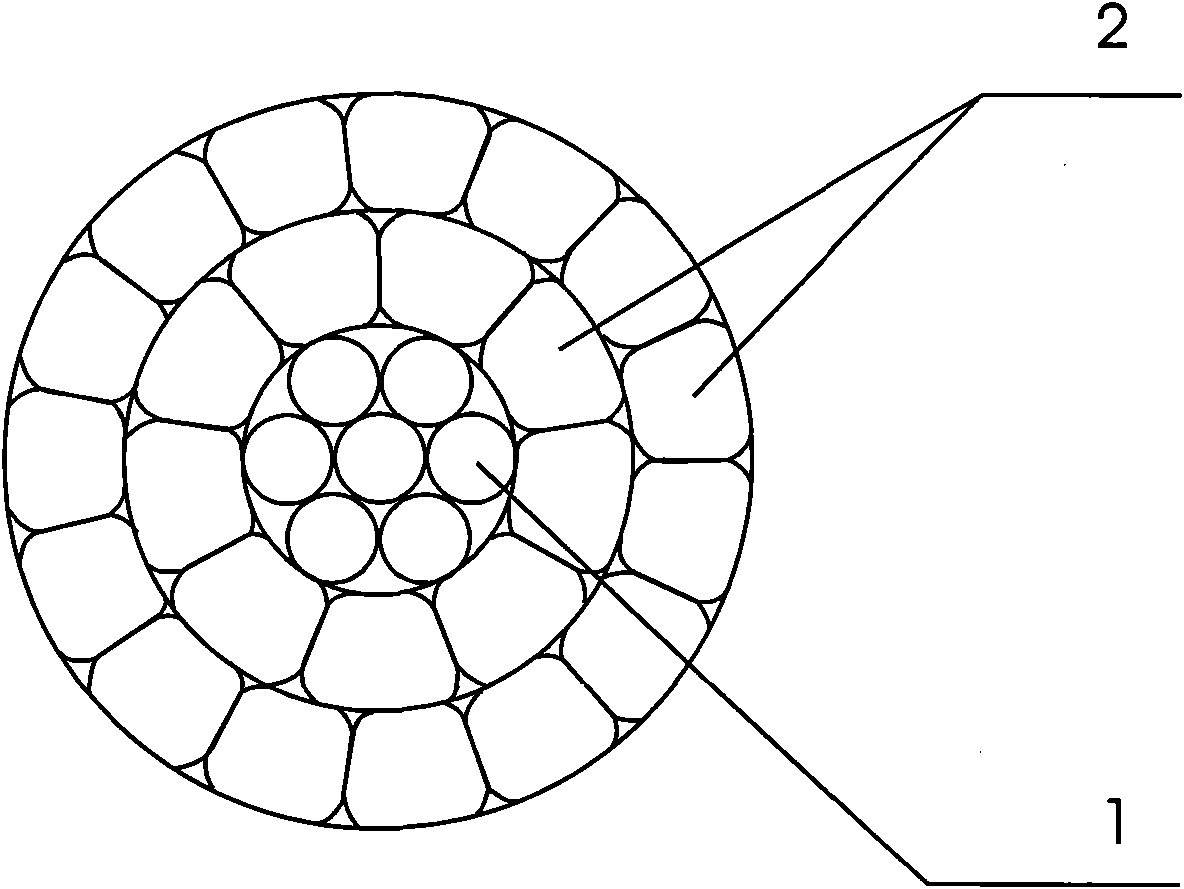

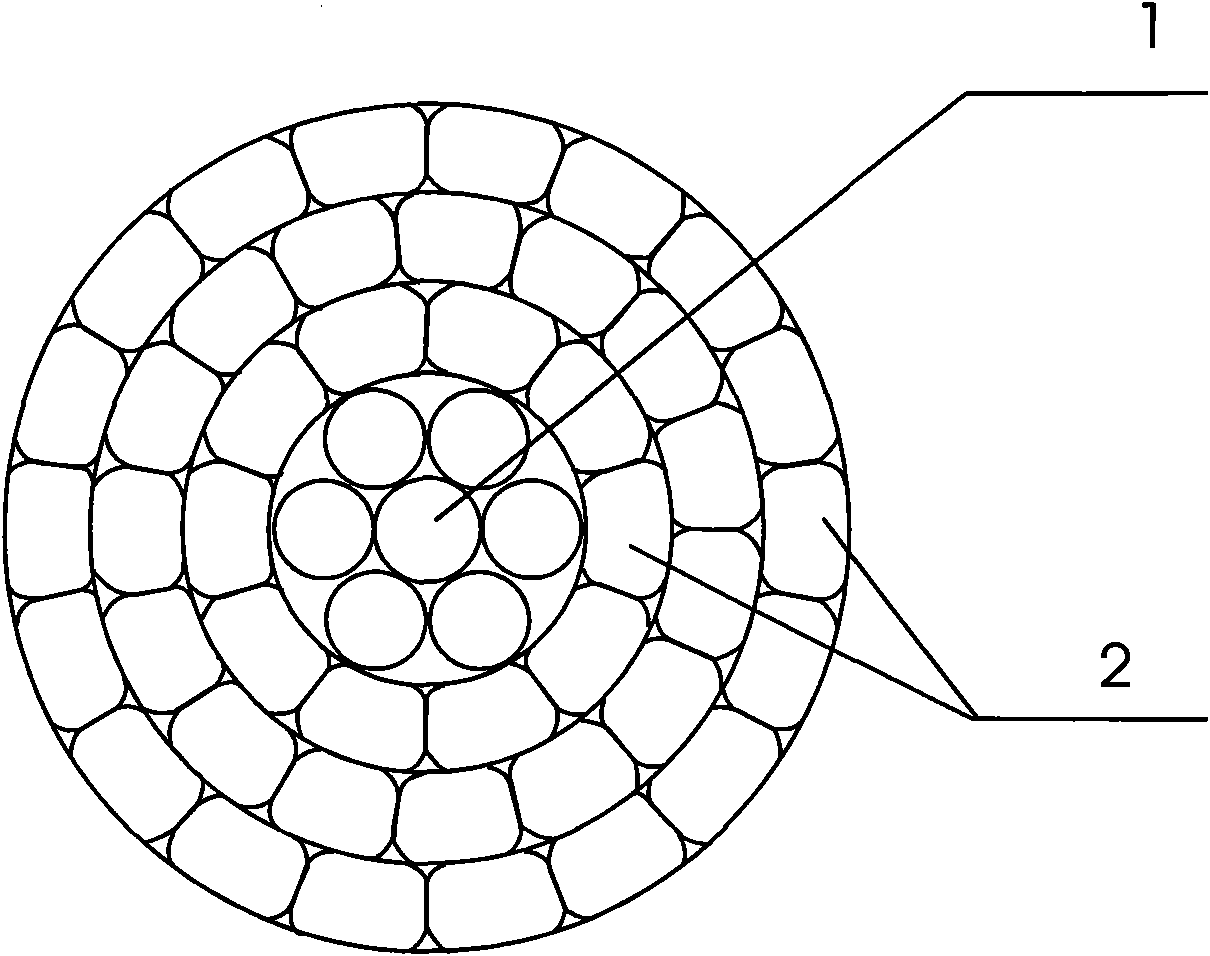

High-conductivity anti-icing lead and production method thereof

A high-conductivity, manufacturing method technology, applied in cable/conductor manufacturing, conductors, circuits, etc., can solve problems such as the collapse of wire poles and towers, lack of ice resistance, wire fittings falling off, etc., to achieve long service life, structural Compact, small gap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

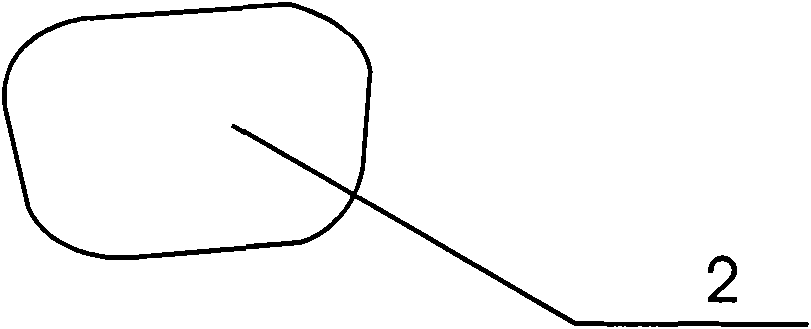

[0024] Example 1, the A4 type Φ9.5mm electrical round aluminum rod conforming to the GB / T3954-2008 standard is selected, the tensile strength of the aluminum rod is 113MPa, the elongation is 12%, and the resistivity is 27.86nΩ·m at 20°C. The temperature of the lubricating oil is not higher than 60°C, (1) The nominal cross-section of the drawing is 9.992mm 2 There are 15 tile-shaped aluminum single wires, the wire drawing speed is controlled at 9m / min, and a total of 8 dies are used for drawing. The first 5 dies use ordinary circular cross-section wire drawing dies, and the drawing elongation coefficient is controlled between 1.29 and 1.30 per pass. 6. The 7-way mold adopts an elliptical cross-section wire drawing die, the wire drawing elongation coefficient is controlled at 1.27 per line, and the approximate cross-sectional area of the mold is 15.2mm 2 、12.0mm 2 , the eighth die is a tile-shaped wire drawing die, and the drawing elongation coefficient is controlled at 1.18....

Embodiment 2

[0025] Example 2, choose an A4 type Φ9.5mm electrical round aluminum rod conforming to the GB / T3954-2008 standard, the aluminum rod has a tensile strength of 110MPa, an elongation of 12%, and a resistivity of 27.81nΩ·m at 20°C. The temperature of the lubricating fluid is not higher than 60°C, (1) The nominal cross-section of the drawing is 9.745mm 2 There are 18 tile-shaped aluminum single wires, and the wire drawing speed is controlled at 9m / min. When a total of 8 dies are used for drawing, the first 5 dies use ordinary circular cross-section wire drawing dies, and the drawing elongation coefficient is controlled between 1.29 and 1.30 per pass. The 6th and 7th molds adopt oval cross-section wire drawing dies, the wire drawing elongation coefficient is controlled at 1.26 per lane, and the approximate cross-sectional area of the mold is 14.8mm 2 、11.7mm 2 , the eighth die is a tile-shaped wire drawing die, and the drawing elongation coefficient is controlled at 1.18. Conside...

Embodiment 3

[0026] Example 3, A2-type Φ9.5mm electrical round aluminum rod conforming to the GB / T3954-2008 standard is selected, the tensile strength of the aluminum rod is 105MPa, the elongation is 14%, and the resistivity is 27.79nΩ·m at 20°C. The temperature of drawing lubricating oil is not higher than 60°C, (1) The nominal section of drawing is 12.471mm 2 There are 15 tile-shaped aluminum single wires, the wire drawing speed is controlled at 7m / min, and a total of 7 dies are used for drawing. The first 4 dies use ordinary circular cross-section wire drawing dies, and the drawing elongation coefficient is controlled between 1.31 and 1.32 per pass. 5 and 6 molds adopt oval cross-section wire drawing die, the drawing elongation coefficient is controlled at 1.27 per lane, and the approximate cross-sectional area of the mold is 19.0mm 2 、15.0mm 2 , the seventh mold is a tile-shaped wire drawing die, and the drawing elongation coefficient is controlled at 1.19. Considering that the wire...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com