Desulfurizing method of bleached semi-finished canned food

A technology for canned food and semi-finished products, applied in the field of desulfurization, which can solve the problems of poor desulfurization uniformity, long production cycle, and abundant fresh water resources, and achieve the effects of cost reduction, high unit output, and saving fresh water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

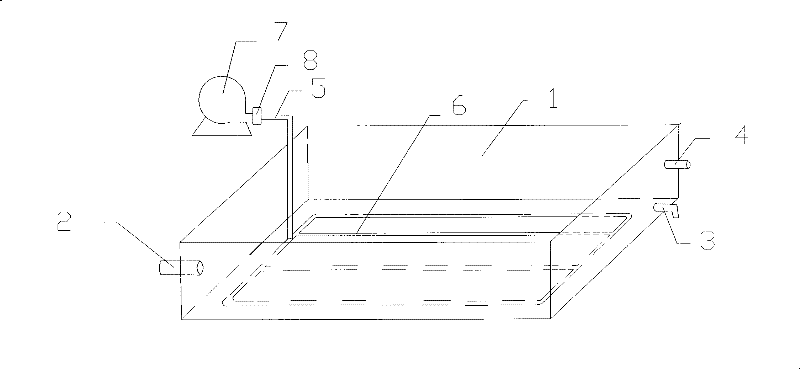

[0020] exist figure 1 The shown desulfurization tank 1 is respectively provided with a water inlet hole 2, a drain hole 3 and an overflow hole 4. The bottom of the tank is equipped with a corresponding air injection device. The air injection device is composed of a connecting pipe 5 and an air injection pipe row 6. The upper end of the connecting pipe is connected with the blower 7 arranged outside the desulfurization tank, and the lower end is connected with the air blower 7 located outside the desulfurization tank. And it is connected with the parallel jet pipe row, and the pipe row has four branch pipes juxtaposed, and their two ends are respectively connected with the two end pipes. One end of the jet pipe row is connected with the connecting pipe, and the rest are closed, and air holes are arranged on the downward wall. The front part of the above-mentioned air injection device, that is, the upper end of the connecting pipe, passes through the air filter device 8 and the...

example 2

[0022] Adopt the same desulfurization tank, blower and air filter as Example 1. Put 400 kg of bleached whole Agaricus bisporus into the above-mentioned desulfurization tank filled with 600 kg of tap water, start the blower, and the air hole of the air injection device will eject air flow. After 3 hours, turn off the blower, drain the water in the tank, and then inject 600 kg Fresh tap water, start the blower again, the air blower will continue to eject the airflow, and after 3 hours, turn off the blower again, drain the water in the tank, inject 600 kg of fresh tap water, start the blower again, and the air injection device will continue to eject the airflow, After another 3 hours, turn off the blower again, take out the material, and measure its sulfur content average to be 12ppm, and the sampling error in the tank is only 1ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com