Regenerated rubber magnet and preparation method and application thereof

A technology of recycled rubber and rubber magnets, applied in applications, other household appliances, household appliances, etc., can solve the problems of low recycling value, difficult recycling, carbonization of rubber powder, etc., to achieve a smooth surface without impurities, good magnetic and physical properties. performance, the effect of avoiding carbonization of rubber powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

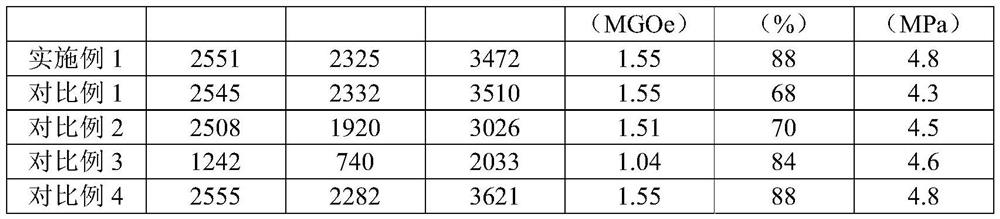

Embodiment 1

[0040] This embodiment provides a regenerated rubber magnet, the preparation method of which comprises the following steps:

[0041] (1) According to the mass ratio of 1:1, a total of 10kg of vulcanized waste rubber magnets and ferrite magnetic powders are mixed on the internal mixer for a period of mixing. The mixing process is: the waste rubber magnets are put into the internal mixer and iron is added. Oxygen magnetic powder, mixed to 132 ℃, and then poured out.

[0042] (2) Put the uniformly mixed waste rubber magnets and ferrite magnetic powders in a microwave oven to perform microwave desulfurization once, with a microwave frequency of 2000MHz and a time of 42s.

[0043] (3) Put the waste rubber after one microwave desulfurization into the internal mixer, add 0.5% by mass of naphthenic oil and mix it, and pour it out after mixing it to 123°C.

[0044] (4) Put the mixed material in step (3) into a microwave oven for secondary microwave desulfurization to obtain desulfuriz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com