Plaster wall cloth production method and production device thereof

A production method and production equipment technology, applied in the field of gypsum wall covering production and gypsum wall covering production equipment, can solve problems such as low efficiency and unstable quality, and achieve the effects of improving quality, easy solidification, and clear patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of production method of gypsum wall cloth, it comprises the following steps:

[0031] (1) Lay the base material of gypsum wall covering - fiber cloth on the patterned soft mold sheet;

[0032] (2) Spray water on the fiber cloth to make it moist;

[0033] (3) Sprinkle a layer of gypsum powder evenly on the wet fiber cloth;

[0034] (4) Spray water on the gypsum powder to make the gypsum powder moist into gypsum slurry;

[0035] (5) Press and grind on the gypsum slurry with a tool, so that the gypsum slurry passes through the fiber cloth to reach the other side of the fiber cloth, and embosses the gypsum slurry on the patterned soft mold;

[0036] (6) After the gypsum slurry is solidified, the fiber cloth with gypsum is demoulded from the soft mold sheet to form a gypsum wall covering;

[0037] (7) Drying the demoulded gypsum wall covering to become a finished gypsum wall covering.

Embodiment 2

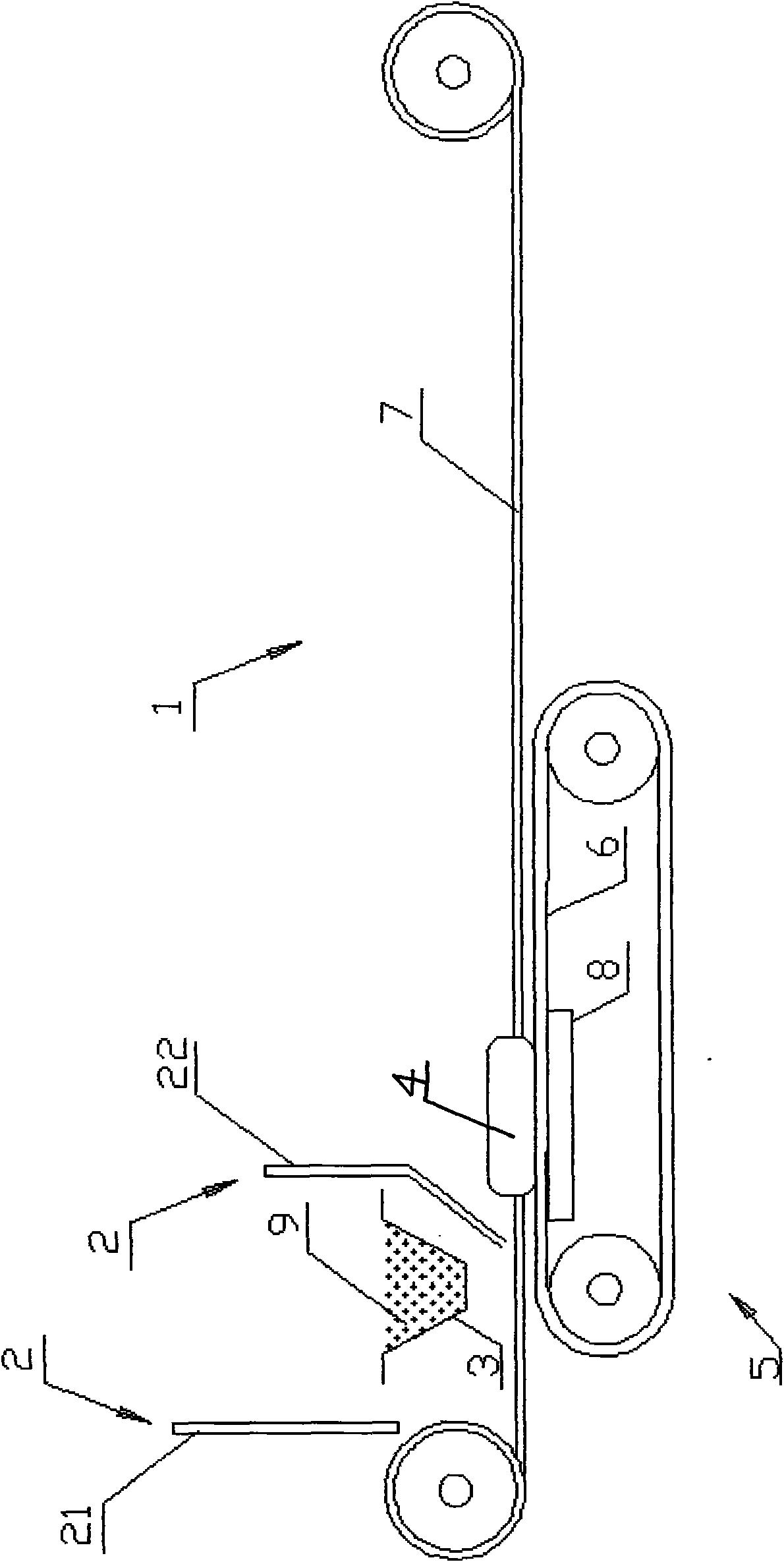

[0039] Such as figure 1 As shown, it is a kind of gypsum wall covering production equipment designed to realize the method of Example 1, which includes a drum type coil conveying mechanism 1, a water spray pipe 2, a hopper 3, a slide plate 4, a vibration platform 8, and a flat belt conveyor Type embossing mechanism 5; The flat belt conveying embossing mechanism 5 is located directly below the drum-type coil conveying mechanism 1, and the flat belt conveying embossing mechanism 5 has the same running direction as the drum-type coil conveying mechanism 1 and running speed; the flat belt in the flat belt conveying embossing mechanism 5 is a soft mold sheet 6 with patterns; The coils 7 in the mechanism overlap; the hopper 3 and the slide plate 4 are sequentially installed above the roller-type coil conveying mechanism 1; the length of the outlet of the hopper 3 is equal to the width of the coil 7, and the length of the slide 4 is greater than that of the coil 7 The width of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com