Method for cutting silicon chips

A silicon wafer cutting and cutting line technology, which is applied to fine working devices, stone processing equipment, manufacturing tools, etc., can solve the problems of cumulative deviation of cutting lines, waste of cutting lines, and uneven thickness of silicon wafers, so as to reduce the difference in thickness, Effect of improving utilization rate and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

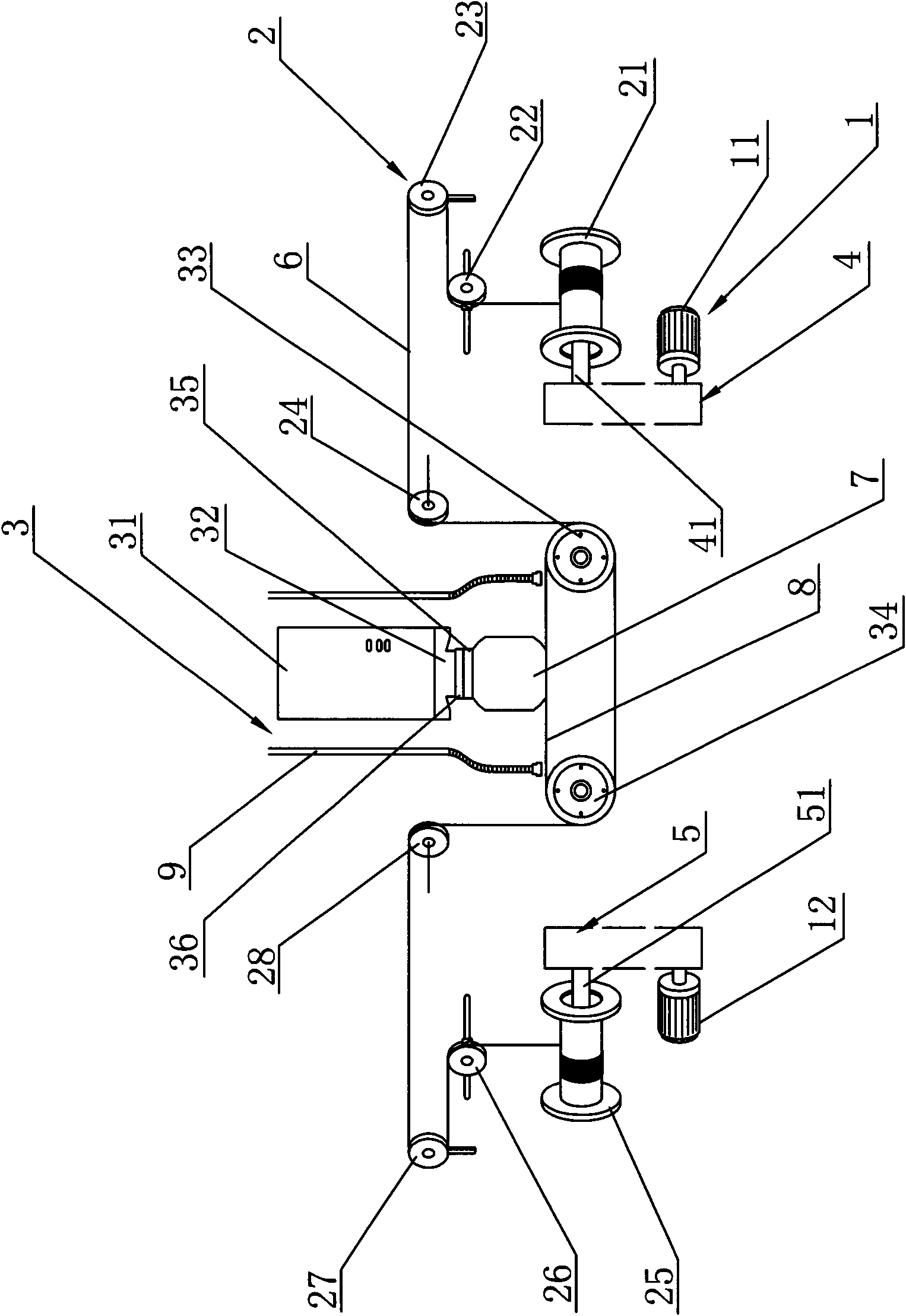

[0014] Embodiment one: the silicon wafer cutting method of the present invention can be used on the existing silicon wafer cutting machine, and existing silicon wafer cutting machine is as figure 1As shown, it includes a housing (not shown in the figure), and a driving device 1, a cable arrangement 2, a cutting chamber 3 and a control system (not shown in the figure) are arranged in the housing. The top of the cutting chamber 3 is provided with a working platform 31, the working platform 31 is provided with a workpiece fixture 32, and the workpiece fixture is movably connected with a splint 36 for clamping the silicon rod 7, and the bottom of the cutting chamber 3 is provided with a first guide wheel 33 and The second guide wheel 34, the first guide wheel 33 is radially provided with a plurality of first wire grooves (not shown in the figure), and the second guide wheel 34 is radially provided with a plurality of wire grooves corresponding to the first wire grooves. The second...

Embodiment 2

[0022] Embodiment two: this implementation is basically the same as embodiment one, and the only difference is that in the present embodiment, the descending speed is set to 25mm / min, the advancing speed is set to 9.5m / s, and the pay-off spool driving motor 11 The line length of driving pay-off spool 21 forward pay-off is set as 250m, and the line length of take-up spool drive motor 12 driving take-up spool 25 reverse pay-off is set as 60m, so when pay-off spool drive motor 11 and take-up spool After the drive motor 12 rotates in the forward direction for about 26.3s, the drive motor 11 of the pay-off spool and the drive motor 12 of the take-up spool need to rotate in the reverse direction, and the time of reverse rotation is about 6.3s. After the bobbin drive motor 12 reversely rotates for 6.3s, the pay-off bobbin drive motor 11 and the take-up bobbin drive motor 12 rotate forwardly again.

Embodiment 3

[0023] Embodiment 3: This embodiment is basically the same as Embodiment 1 and Embodiment 2. The only difference is that in this embodiment, the descending speed is set to 28mm / min, and the traveling speed is set to 11.5m / s. Line spool drive motor 11 drives the line length of pay-off spool 21 forward pay-off to be 265m, and the line length of take-up spool drive motor 12 to drive take-up spool 25 reverse pay-off is set to 60m, so when pay-off spool drive motor After 11 and take-up spool drive motor 12 rotate forward for about 23s, pay-off spool drive motor 11 and take-up spool drive motor 12 need to rotate in reverse, and the time for reverse rotation is about 5.2s. 11 and take-up spool drive motor 12 reversely rotated 5.2s after the pay-off spool drive motor 11 and take-up spool drive motor 12 forwardly rotated again.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Line length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com