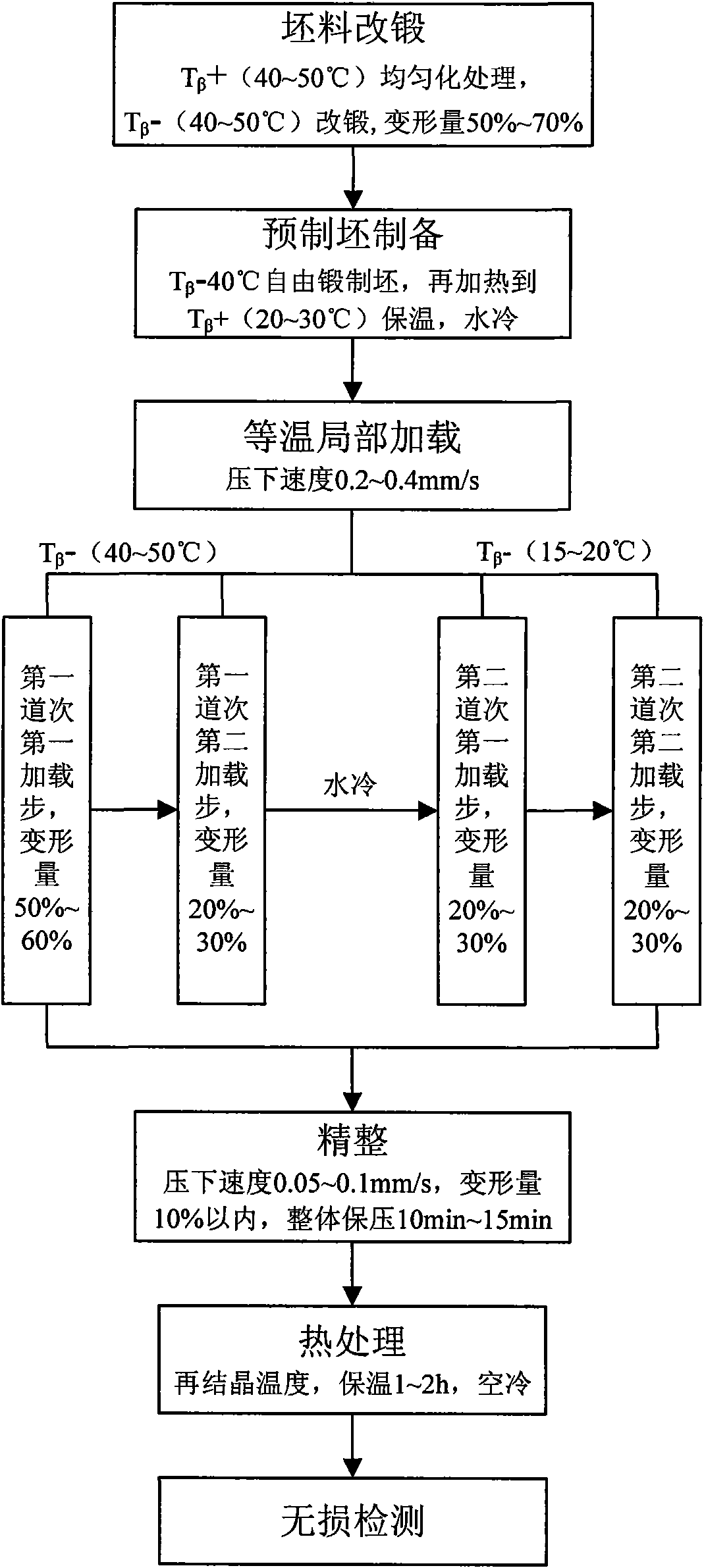

Method for realizing near alpha titanium alloy dual-property employing local loading process

A local loading, titanium alloy technology, applied in the field of near-alpha titanium alloy dual performance, can solve the problems of weak interface, complex and difficult to control process, low production efficiency, etc., to achieve long strength, high room temperature plasticity, high high temperature strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

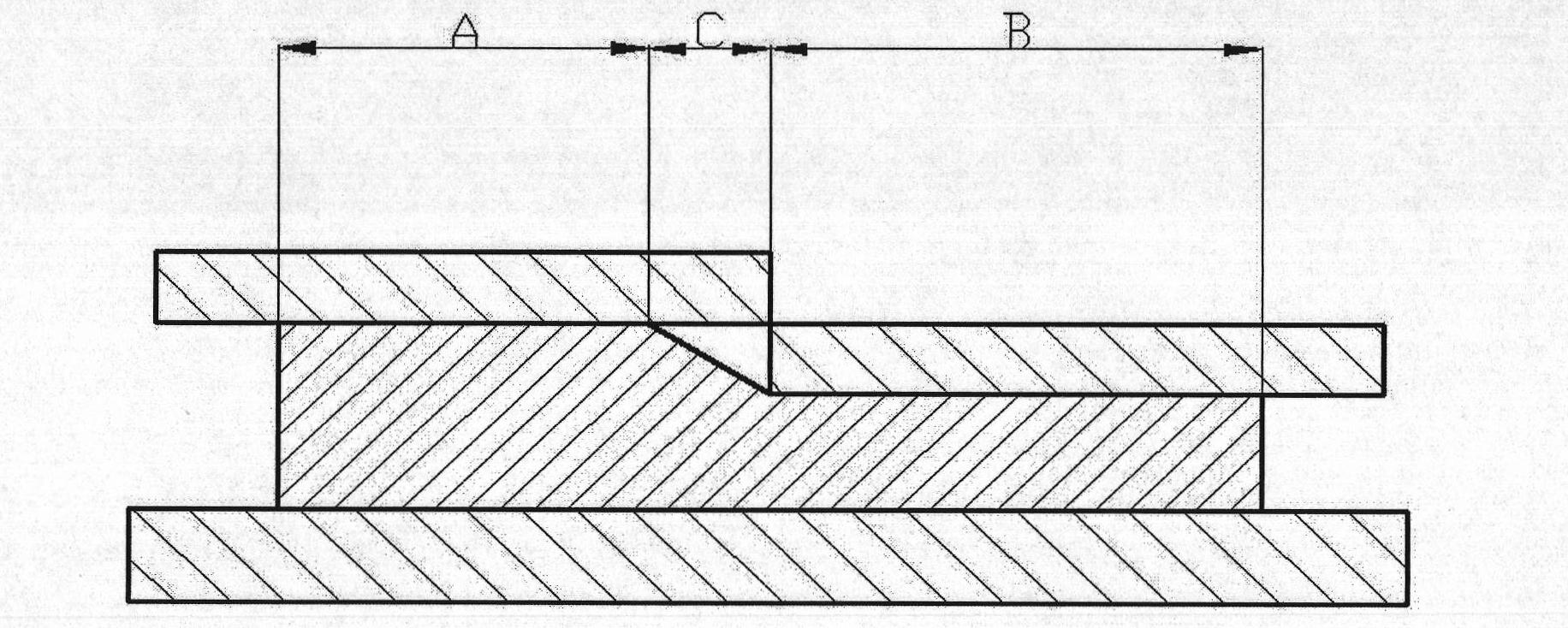

Method used

Image

Examples

Embodiment 1

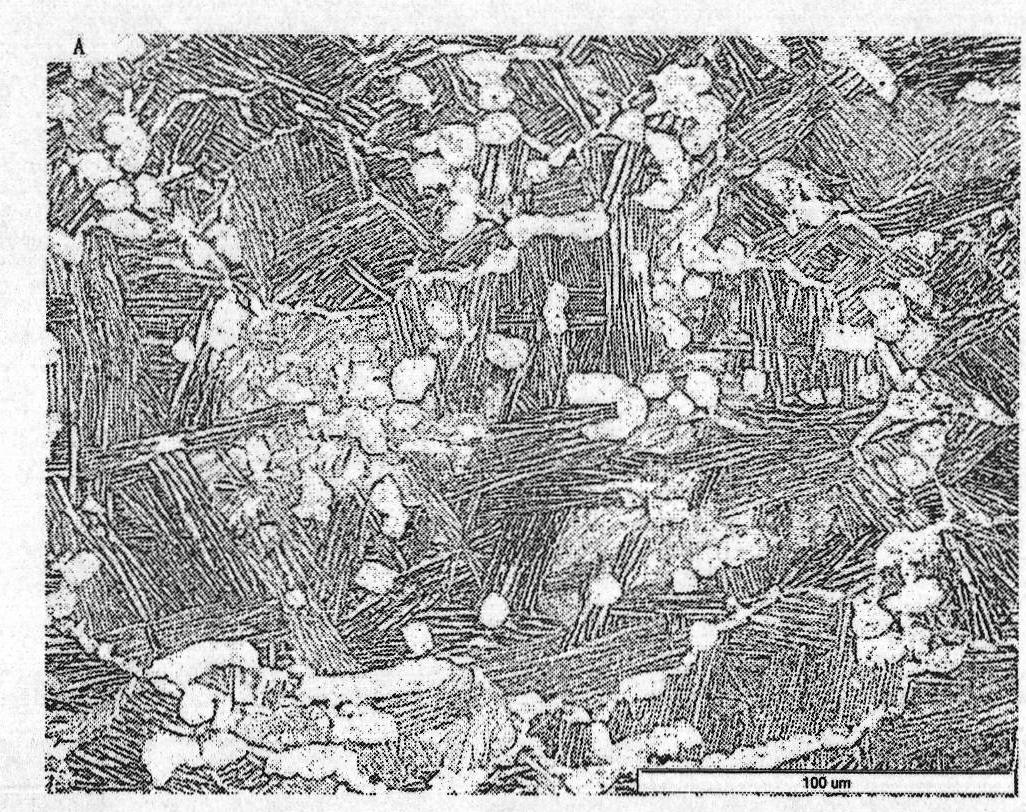

[0037] This embodiment is a method for realizing the dual performance of near-alpha titanium alloy rectangular cross-section beams by adopting a local loading process.

[0038] The raw material of this example is a TA15 titanium alloy bar with a diameter of Φ300mm, the nominal composition is Ti-6Al-2Zr-1Mo-1V, and the phase transition point T β It is 990°C, and the recrystallization temperature is 830°C. The specific process is as follows:

[0039] The first step, blank forging

[0040] Heat the bar in a box-type resistance furnace to T β +40°C, keep warm for 2 hours, upsetting and elongating on the fast forging machine, the deformation amount is 50% to 70%, water-cooled to 25°C after forging; then the obtained blank is heated to T β -50°C, keep warm for 2h, carry out re-forging on a quick forging machine, repeatedly upsetting and elongating, the deformation amount is 50% to 70%, and water-cooled to 25°C after forging.

[0041] The second step, preform preparation

[0042...

Embodiment 2

[0055] This embodiment is a method for realizing the dual performance of near-alpha titanium alloy rectangular cross-section beams by adopting a local loading process.

[0056] The raw material of this example is a TA15 titanium alloy rod with a diameter of Φ500mm, the nominal composition is Ti-6Al-2Zr-1Mo-1V, and the phase transition point T β It is 990°C, and the recrystallization temperature is 830°C. The specific process is as follows:

[0057] The first step, blank forging

[0058] Heat the bar in a box-type resistance furnace to T β +50°C, keep warm for 1h, upsetting and elongating on the fast forging machine, the deformation amount is 50% to 70%, water-cooled to 25°C after forging; then the obtained blank is heated to T β -40°C, heat preservation for 1h, re-forging on the fast forging machine, repeated upsetting and elongation, the deformation amount is 50% to 70%, and water-cooled to 25°C after forging.

[0059] The second step, preform preparation

[0060] In the...

Embodiment 3

[0073] This embodiment is a method for realizing the double performance of near-alpha titanium alloy disc by adopting partial loading process.

[0074] The raw material of this example is TA15 titanium alloy bar with Φ400mm, nominal composition Ti-6Al-2Zr-1Mo-1V, phase transition point T β It is 990°C, and the recrystallization temperature is 830°C. The specific operation is as follows:

[0075] The first step, blank forging

[0076] Heat the bar in a box-type resistance furnace to T β +40°C, keep warm for 2 hours, upsetting and elongating on the fast forging machine, the deformation amount is 50% to 70%, water-cooled to 20°C after forging; then the obtained blank is heated to T β -40°C, heat preservation for 2h, re-forging on the fast forging machine, repeated upsetting and elongation, the deformation amount is 50% to 70%, and water-cooled to 20°C after forging.

[0077] The second step, preform preparation

[0078] In the box-type resistance furnace, the reforged billet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com