Method for realizing gamma-TiAl alloy refinement by accurately controlling metastable structure stabilization

A precise control and stabilization technology, applied in the direction of process efficiency improvement, energy efficiency improvement, etc., can solve the problems of difficult to control the size of lamellar clusters, increase the cracking tendency of ingots, and limited degree of refinement. The effect of improving performance, improving room temperature plasticity, and improving the degree of refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

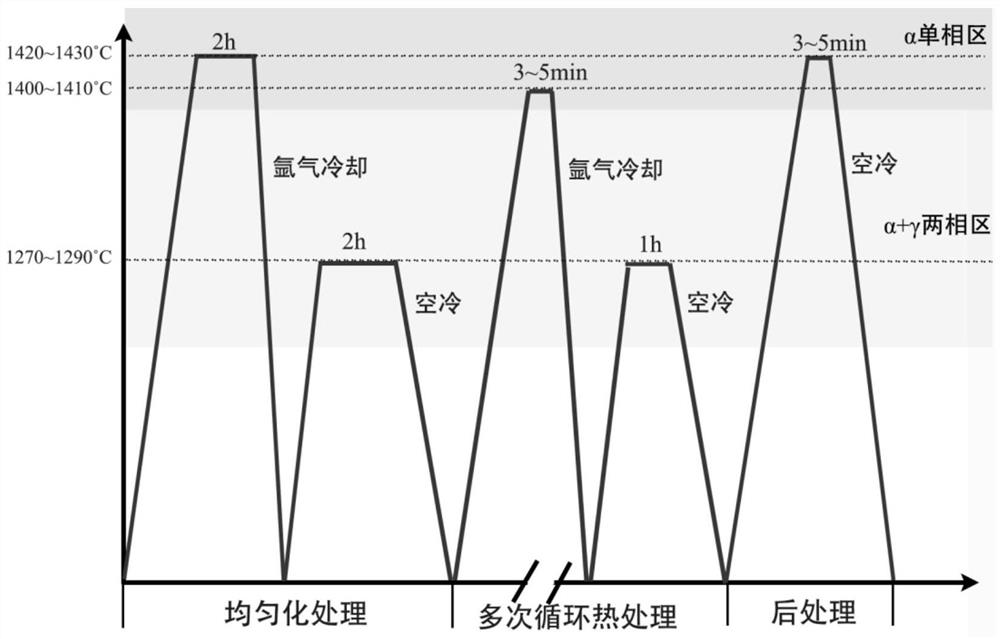

[0030] The γ-TiAl alloy of this embodiment is composed of the following atomic percentages: Al 48.5%, Nb 1.0%, Ta 3.0%, B 0.01%, and the balance is Ti, such as figure 1 As shown, the method of the present embodiment includes the following steps:

[0031] Step 1. Melting of the alloy ingot: the γ-TiAl alloy ingot is prepared by three smelting methods using the cold crucible vacuum induction melting method, and the O introduced into the γ-TiAl alloy ingot by atomic percentage does not exceed 0.05%, and the Fe does not exceed 0.05%. ;

[0032] Step 2, alloy homogenization treatment: put the γ-TiAl alloy ingot prepared in step 1 into a hot isostatic pressing furnace, and perform hot isostatic pressing treatment at a pressure of 200 MPa and a temperature of 1280 °C for 8 hours to obtain The dense TiAl alloy casting is then placed in a box-type heat treatment furnace for homogenization treatment. The specific process is as follows: firstly keep warm at 1430°C for 2 hours in the α s...

Embodiment 2

[0038] The γ-TiAl alloy of this embodiment is composed of the following atomic percentages: Al 47.5%, Nb 1.5%, Cr 1.0%, Ta 2.0%, B 0.05%, and the balance is Ti, such as figure 1 As shown, the method of the present embodiment includes the following steps:

[0039] Step 1. Melting of the alloy ingot: the γ-TiAl alloy ingot is prepared by three smelting methods using the cold crucible vacuum induction melting method, and the O introduced into the γ-TiAl alloy ingot by atomic percentage does not exceed 0.05%, and the Fe does not exceed 0.05%. ;

[0040] Step 2, alloy homogenization treatment: put the γ-TiAl alloy ingot prepared in step 1 into a hot isostatic pressing furnace, and perform hot isostatic pressing treatment at a pressure of 200 MPa and a temperature of 1260 °C for 6 hours to obtain The dense TiAl alloy casting is then placed in a box-type heat treatment furnace for homogenization treatment. The specific process is as follows: firstly keep warm at 1420°C for 2 hours i...

Embodiment 3

[0044] The γ-TiAl alloy of this embodiment is composed of the following atomic percentages: Al 47%, Nb 2.5%, Cr 2.0%, Ta 1.0%, B 0.1%, and the balance is Ti, such as figure 1 As shown, the method of the present embodiment includes the following steps:

[0045] Step 1. Melting of the alloy ingot: the γ-TiAl alloy ingot is prepared by three times of melting by the cold crucible vacuum induction melting method; impurities O and Fe are introduced in the process of the cold crucible vacuum induction melting method, and the γ-TiAl alloy ingot is calculated by atomic percentage. The O introduced into the TiAl alloy ingot does not exceed 0.05%, and the Fe does not exceed 0.05%;

[0046] Step 2, alloy homogenization treatment: put the γ-TiAl alloy ingot prepared in step 1 into a hot isostatic pressing furnace, and perform hot isostatic pressing treatment at a pressure of 200 MPa and a temperature of 1240 °C for 4 hours to obtain Dense TiAl alloy castings are then placed in a box-type ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com