Quickly assembling block

A fast and fast mounting hole technology, applied to roads, helicopter landing platforms, building materials, etc., can solve the problems of material cutting loss, inconvenient cleaning, material waste, etc., and achieve the effects of weight reduction, convenient flow diversion, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

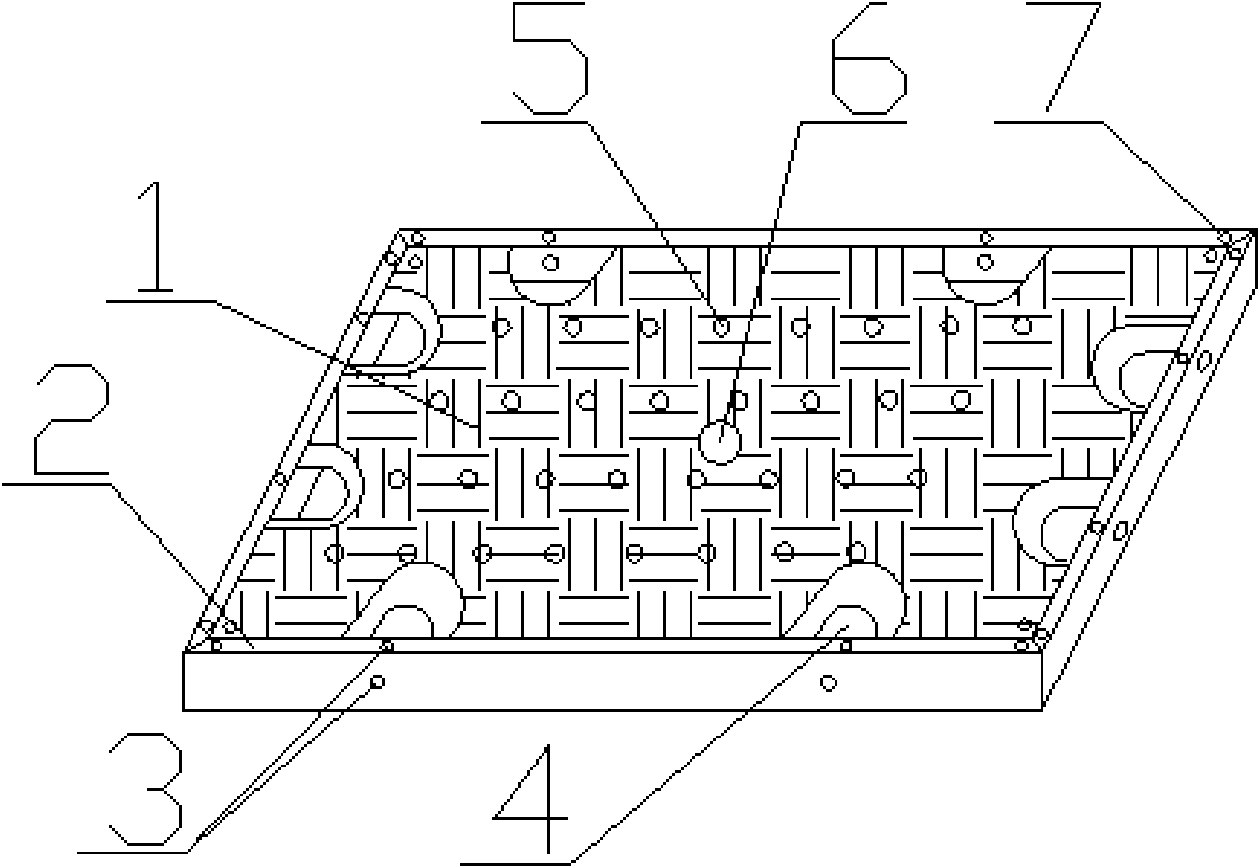

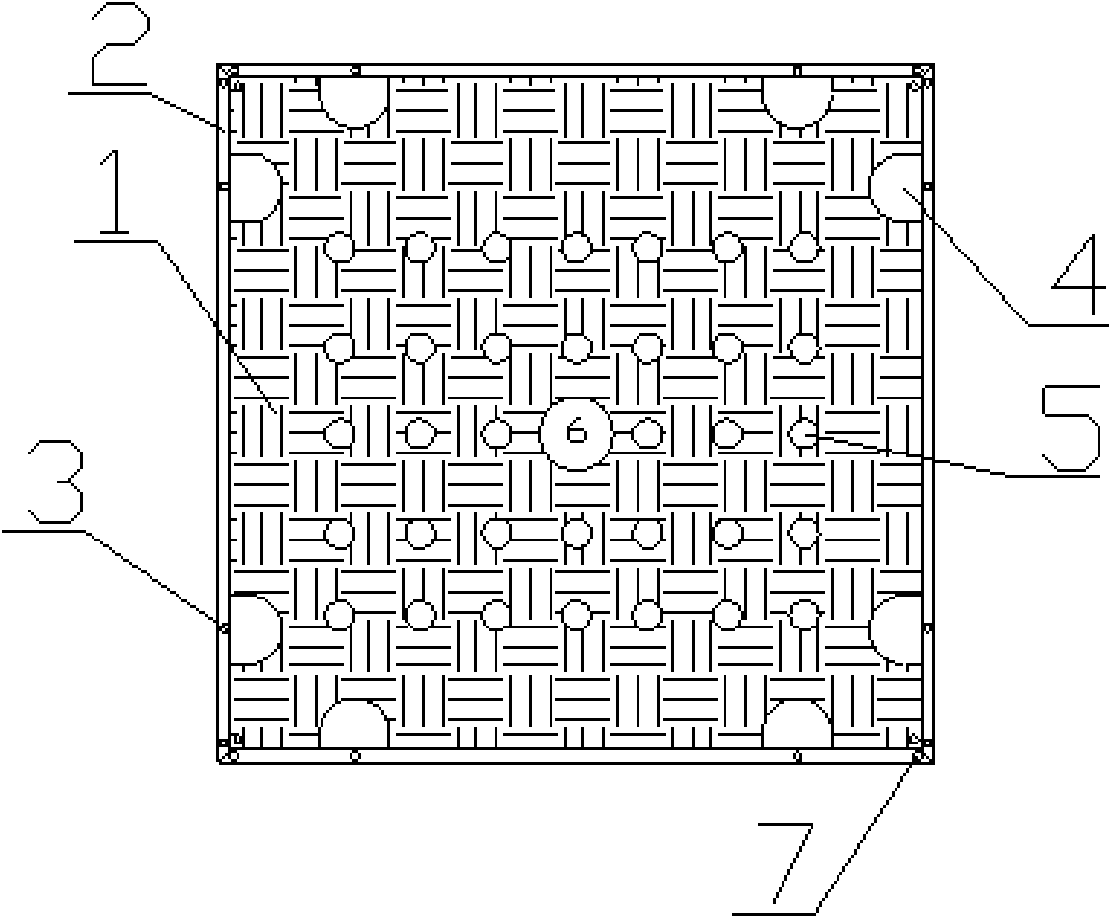

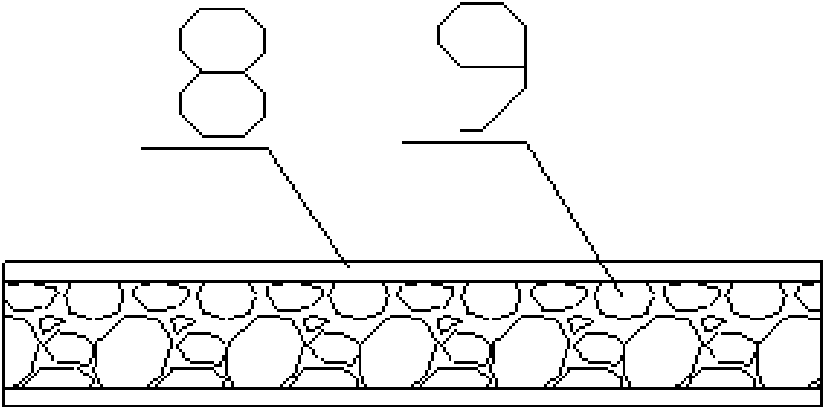

[0018] Example: such as figure 1 , figure 2 with image 3 As shown, the aluminum honeycomb composite structure panel 1 is composed of two layers of aluminum panels 8 and an aluminum honeycomb 9 filled in between. The thickness is 40-200 mm. In order to increase the anti-slip effect, the aluminum panel 8 uses aluminum checkered plates. Cut the finished aluminum honeycomb composite structure panel 1 into a square with the length and width equal to 1000mm~2000mm, and then install the trough frame 2 on the four sides of the cut aluminum honeycomb composite structure panel 1. Bolt holes 3 are provided. The bolt holes 3 include horizontal bolt holes horizontal to the aluminum honeycomb composite structure plate 1 and vertical bolt holes perpendicular to the aluminum honeycomb composite structure plate 1, and are located at the bolt holes 3 on the aluminum honeycomb composite structure plate 1. Bolt mounting holes 4 are provided. The shape of the bolt mounting holes 4 is horseshoe or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length and width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com