Power balance oil extractor

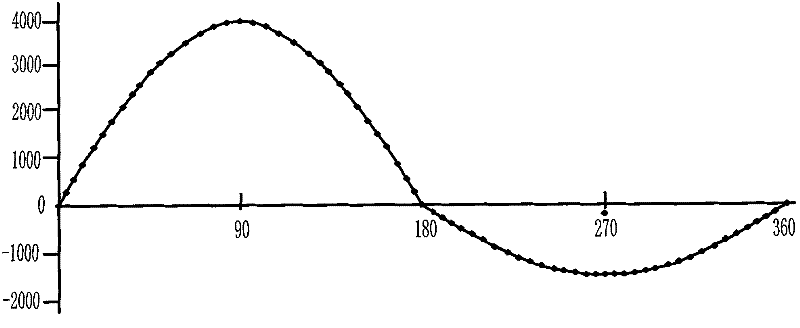

A technology of power balance and pumping unit, which is applied in the direction of mechanical equipment, machine/engine, liquid variable capacity machinery, etc. It can solve the problems of high parameter adjustment and balance adjustment intensity, high energy consumption, and large fluctuations in motor output power. , to achieve the effects of stable output power and load fluctuations, increased effective load rate, and reduced one-time investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing:

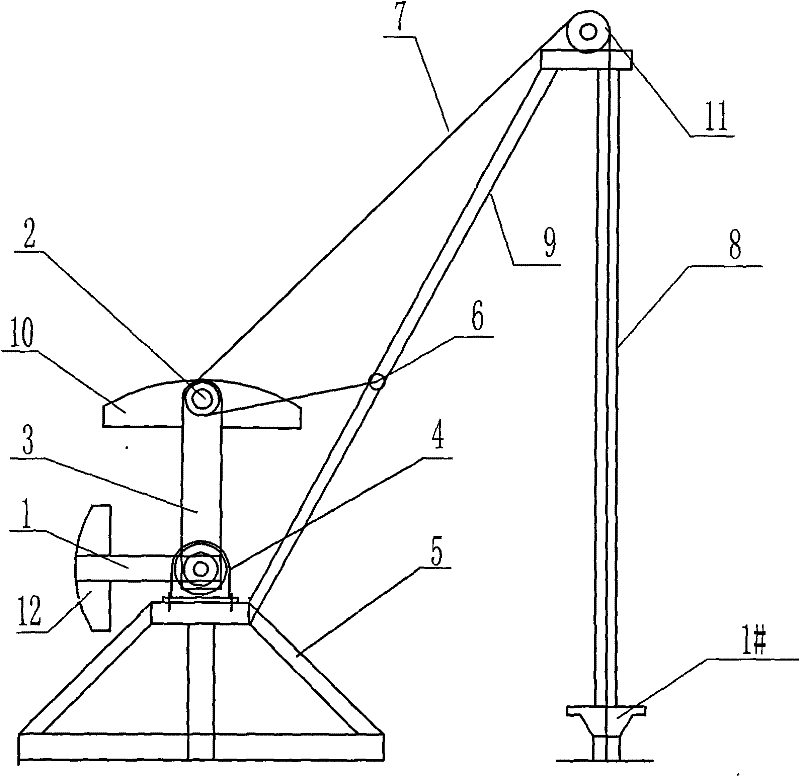

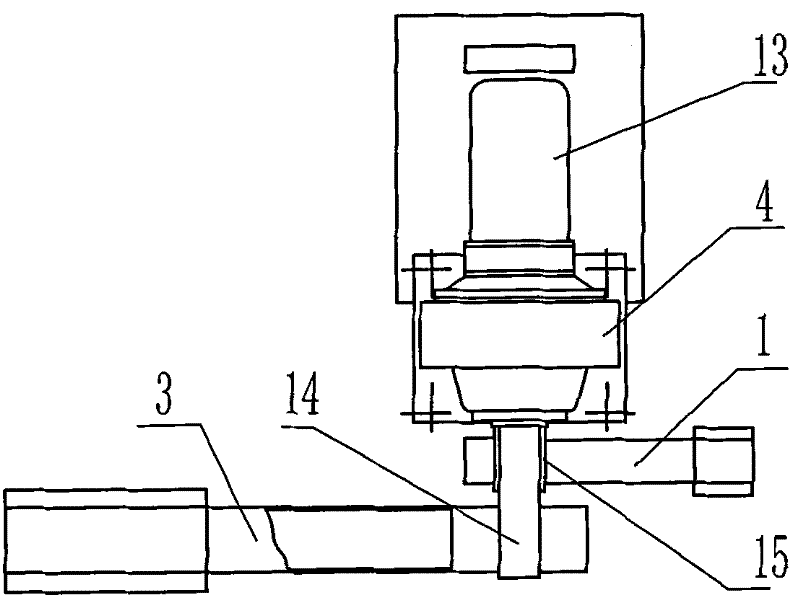

[0017] attached by figure 1 to attach Figure 5 As shown, the power balance pumping unit includes a motor 13, a speed reducer 4, a frame 5, an oil pump crank 3, a power balance weight crank 1, a load counterweight 10, a power balance counterweight 12, a flexible oil pumping rope 7 and a connecting rod. Rod 9 etc. The lower part of the frame 5 fixes the motor 13 and connects it to the reducer 4. The reducer 4 has a main output shaft 14 and an auxiliary output shaft 15. The main output shaft 14 is fixed with the oil pump crank 3, and the oil pump crank 3 is fixed with a load The counterweight 10 drives the load counterweight 10 to rotate in a circle, the power balance weight crank 1 is fixed on the auxiliary output shaft 15, the power balance counterweight 12 is fixed on the power balance weight crank 1, and the power balance counterweight 12 is driven to make a circular m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com