System and method for storing crankcase gases to improve engine air-fuel control

A crankcase and engine technology, applied in the direction of engine control, combustion engine, crankcase ventilation, etc., can solve the problem that the air-fuel control of the engine cannot be improved, and achieve the effect of reducing air-fuel ratio deviation and efficient combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The advantages described herein will be more readily understood by reading the examples of embodiments referred to herein as the "Detailed Description" or when considered in conjunction with the accompanying drawings.

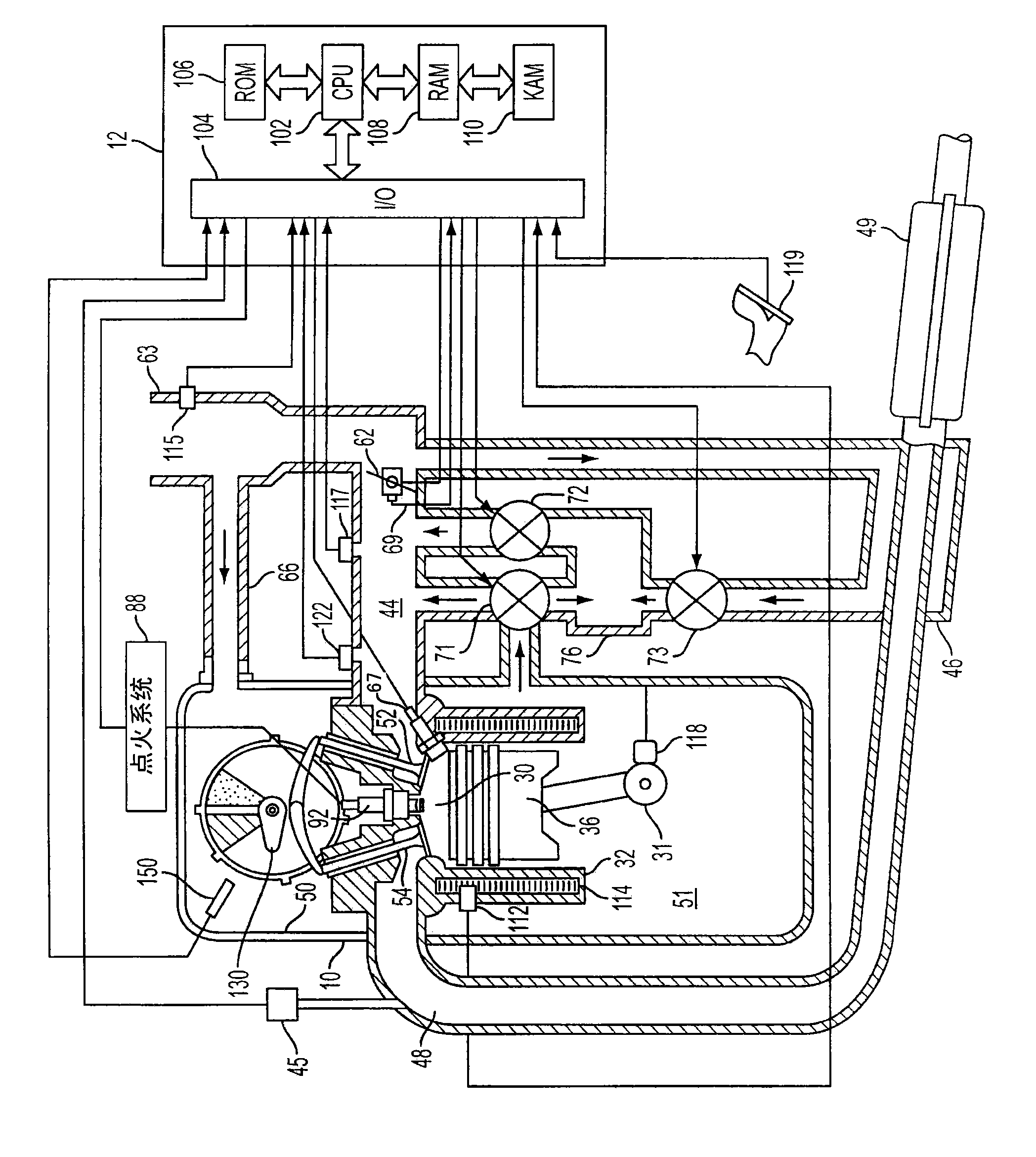

[0013] refer to figure 1 , an internal combustion engine 10 comprising a plurality of cylinders is controlled by an electronic engine controller 12, wherein figure 1 One of several cylinders is shown. Engine 10 includes combustion chamber 30 having piston 36 disposed therein and connected to crankshaft 31 and cylinder walls 32 . Combustion chamber 30 is known to communicate with intake manifold 44 and exhaust manifold 48 via respective intake valve 52 and exhaust valve 54 .

[0014] Each intake and exhaust valve is operated by a mechanical camshaft 130 that rotates by coupling the camshaft to crankshaft 31 . In alternative embodiments, one or more valves may be operated by electronic or hydraulic actuators.

[0015] Fresh air enters an intake plenum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com