Liner wall heat exchange type water tank

A heat exchange type, water tank technology, applied in fluid heaters, lighting and heating equipment, etc., can solve the problems of easy scale heat exchange efficiency, high production cost, low heat transfer coefficient, etc., to achieve increased heat transfer coefficient, stable Working conditions, the effect of increasing the heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, the present invention will be further explained in detail with reference to the drawings.

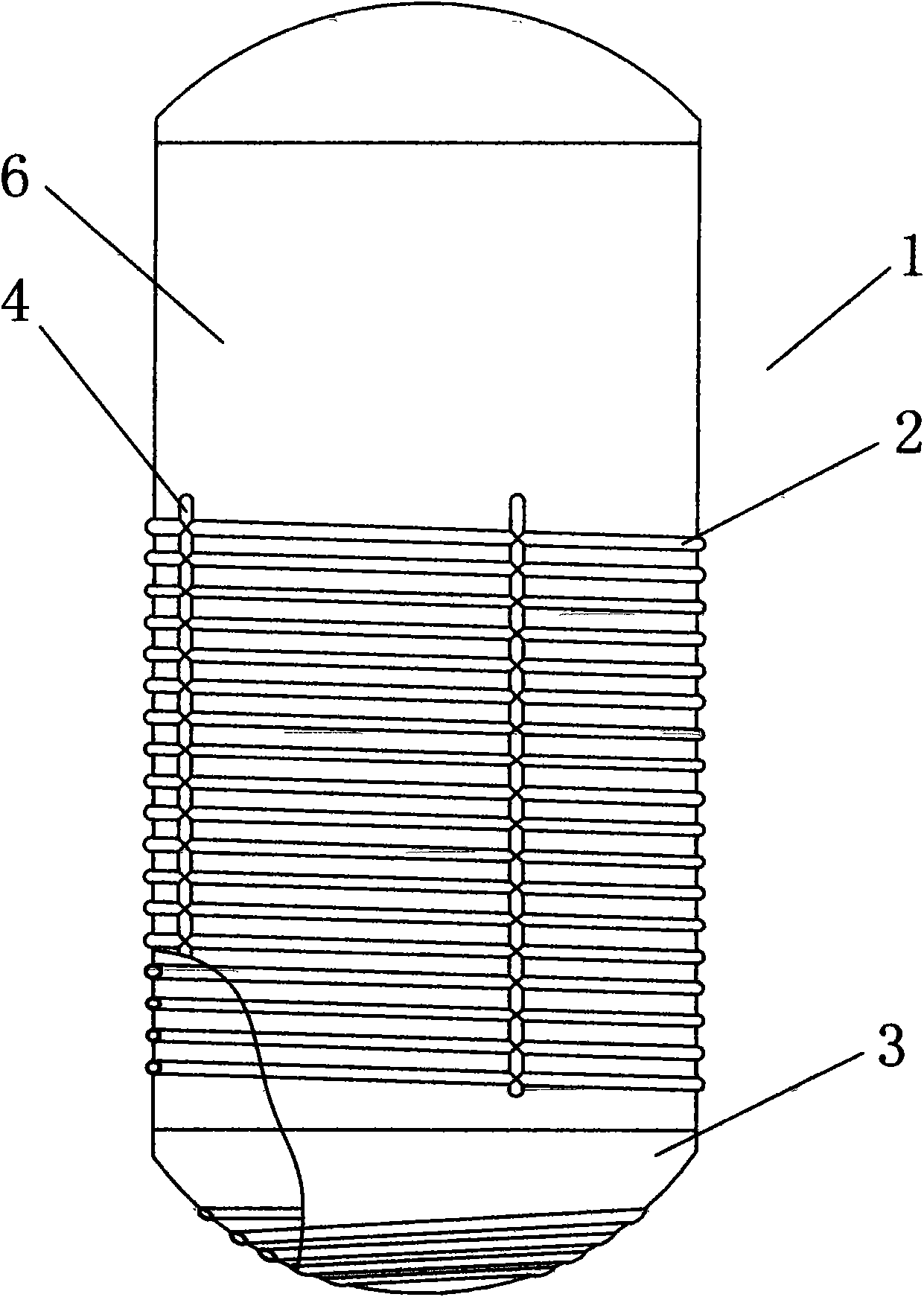

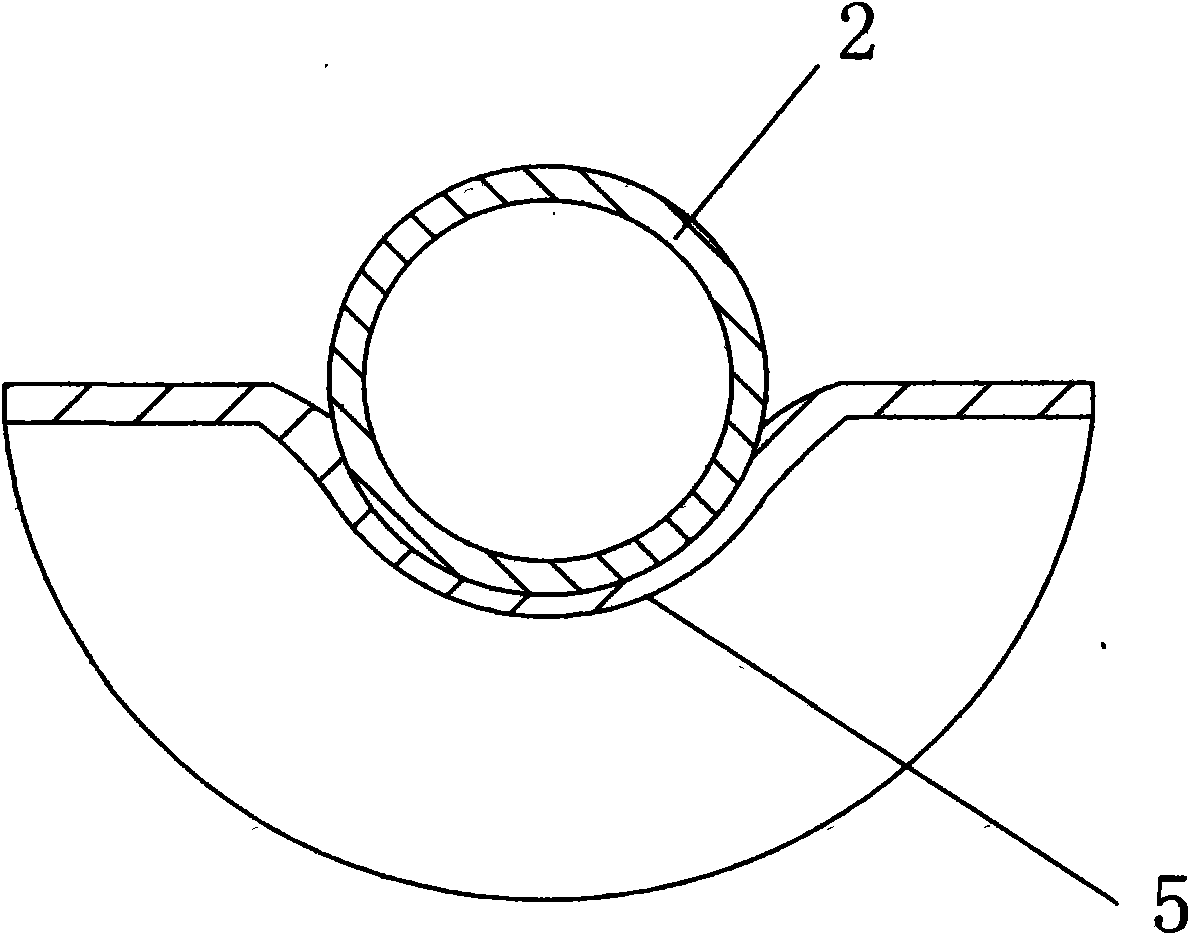

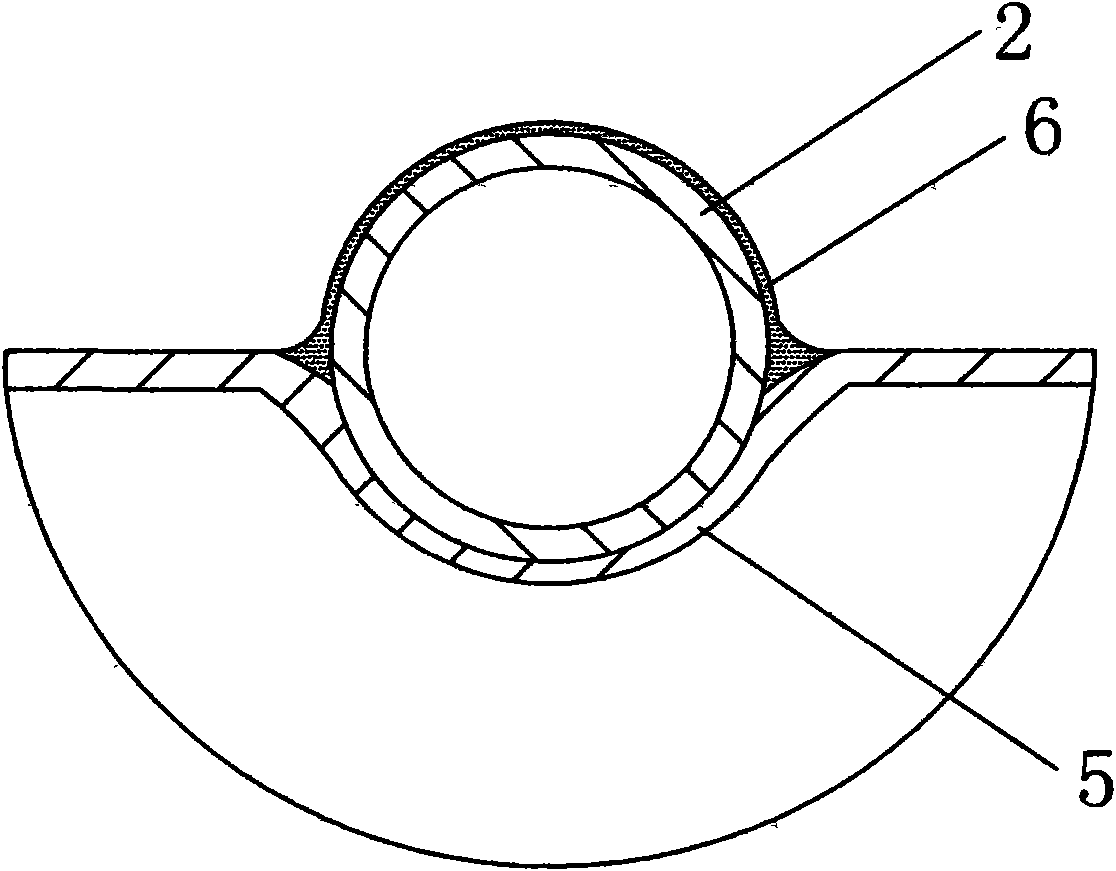

[0022] As shown in the figure, it includes a shell. The shell is provided with an inner liner 1. The inner liner 1 is composed of a middle cylinder body 6 and two ends of the head 3, and an insulating layer is arranged between the inner liner 1 and the shell. Corresponding arc-shaped grooves 5 are provided on the bladder 1 and the head 3 according to the diameter of the working fluid coil 2, and the working fluid coil 2 is tightly wound and fixed in the arc-shaped groove 5. During operation, the working fluid coil 2 wound on the outer wall of the inner liner 1 is used to exchange heat.

[0023] The arc-shaped groove 5 provided on the inner liner 1 and the head 3 has an arc size consistent with the working medium coil 2. The increase in the contact area between the working fluid coil 2 and the inner liner 1 facilitates heat transfer.

[0024] The metal thermally conductive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com