Double-layer energy-saving bulb

An energy-saving light bulb, double-layer technology, applied to the components of gas discharge lamps, etc., can solve the problems of filament length and phosphor content limitations, luminous efficiency and life-span impact, fluorescent tube content decline, etc., to achieve the goal of the whole lamp Easy assembly, low cost, and small color temperature shift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

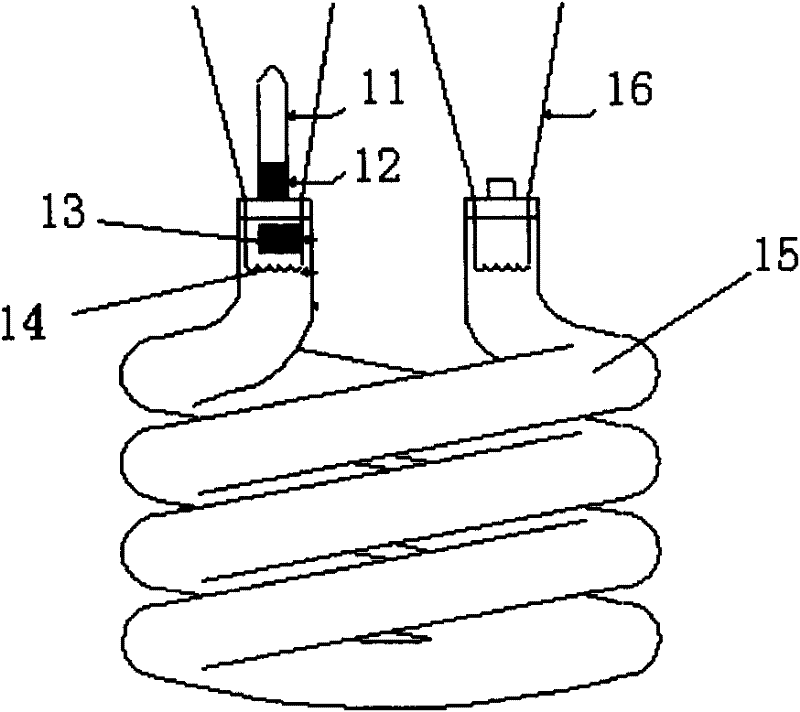

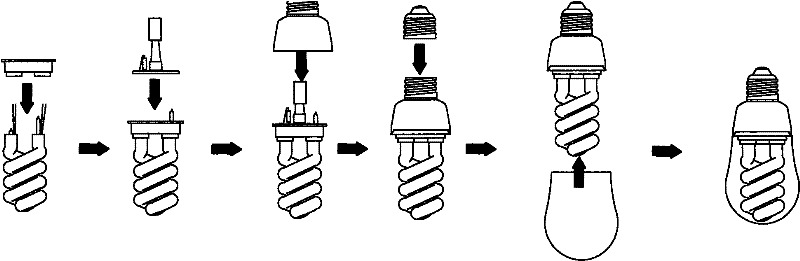

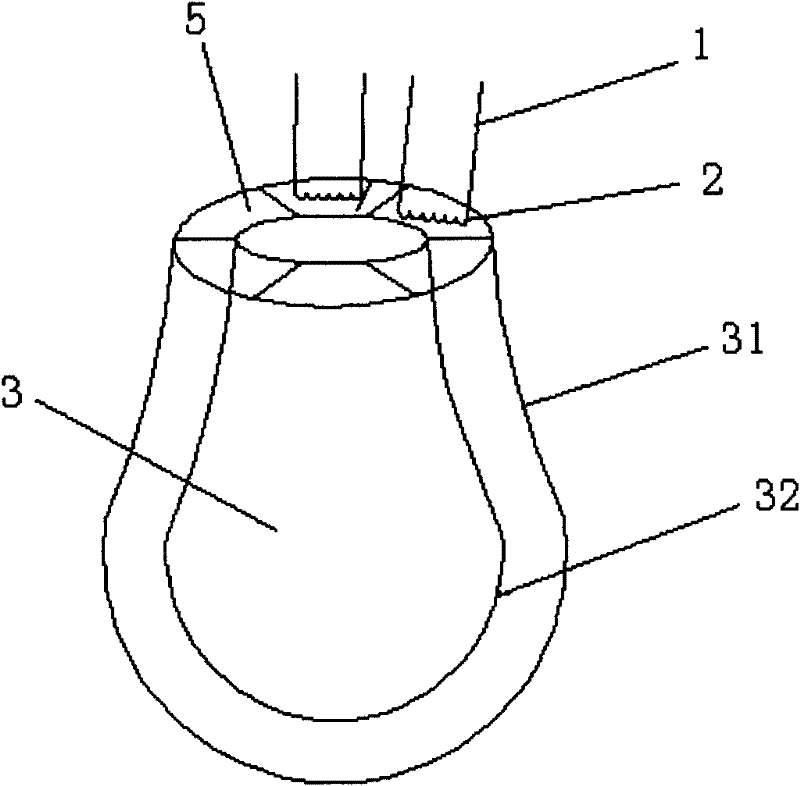

[0027] A kind of double-deck energy-saving light bulb of the present invention, see image 3 , Figure 4 , Figure 5 with Image 6 , the double-layer energy-saving light bulb includes a conductive wire 1, a filament 2 and a lampshade 3, the conductive wire 1 is connected to the filament 2, the lampshade 3 is composed of an outer glass bulb 31 and an inner glass bulb 32, between the outer glass bulb 31 and the inner glass bulb 32 A group of six sealing baffles 33 is provided, and the group of six sealing baffles 33 divides the space formed by the outer glass bulb 31 and the inner glass bulb 32 into a group of six sealing units 34 . In this embodiment, the bottoms of the six sealing baffles 33 intersect to divide the lampshade 3 into a group of six sealing units 34 . According to needs, a group of sealing baffles 33 can also be other numbers. A current path via hole 4 is provided on a single sealing baffle plate 33, and there are five current path via holes 4 in total, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com