Post treatment for desalinated and soft water for balanced water composition supply

A salt water and seawater technology, applied in water/sewage treatment, neutralized water/sewage treatment, multi-stage water/sewage treatment, etc., can solve the problems of not being able to provide naturally, not meeting the proportion requirements, not being provided in water, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

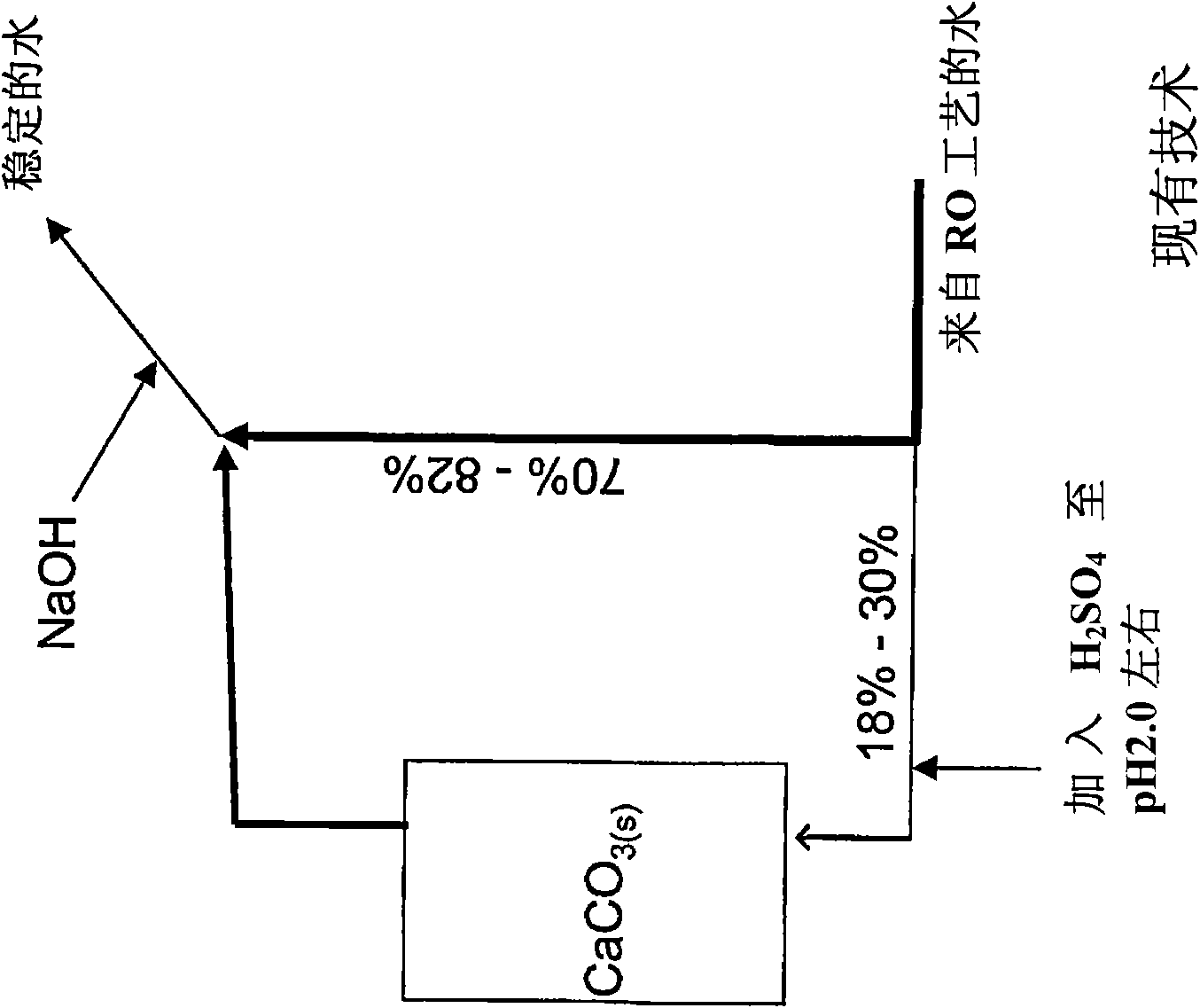

Problems solved by technology

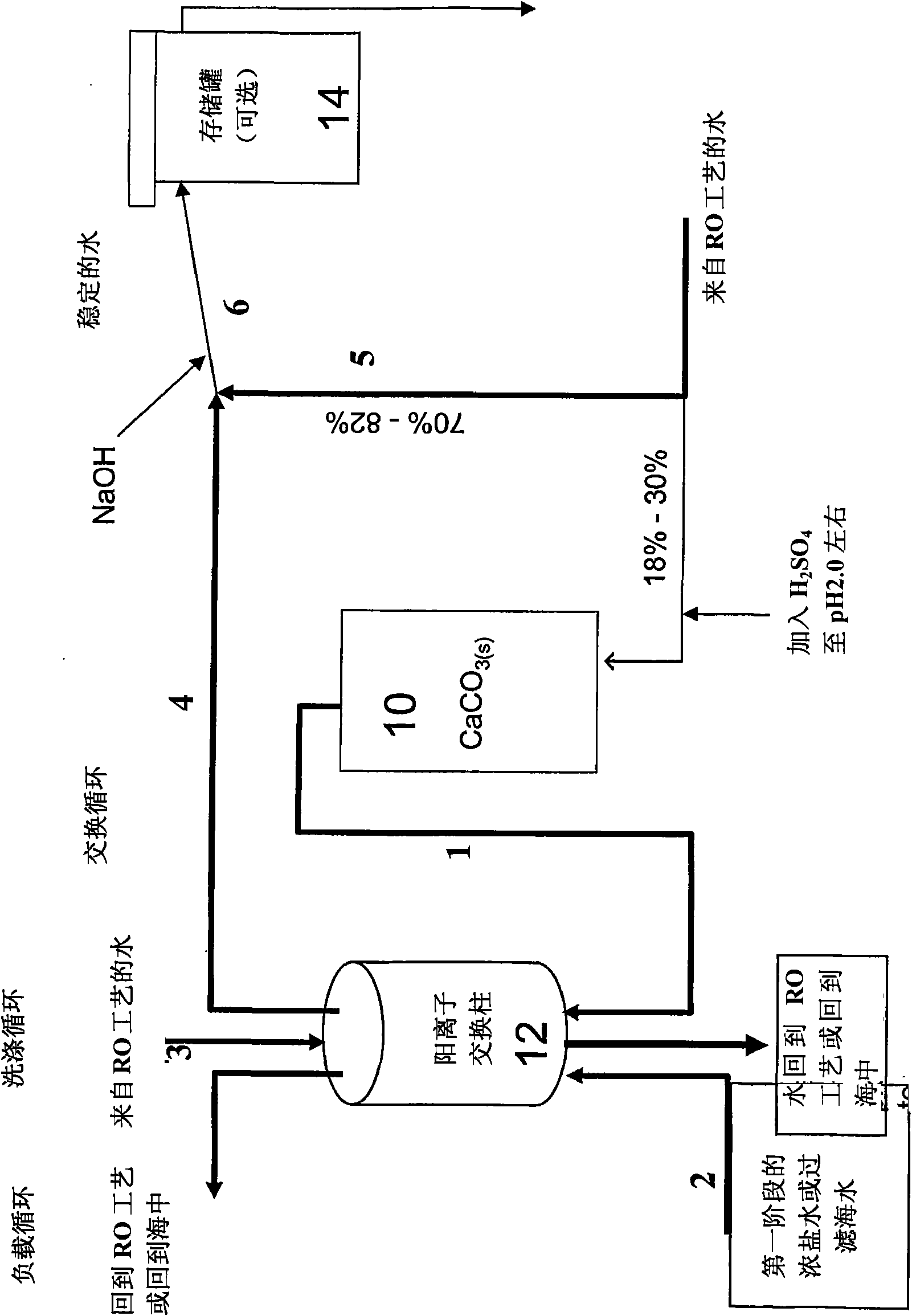

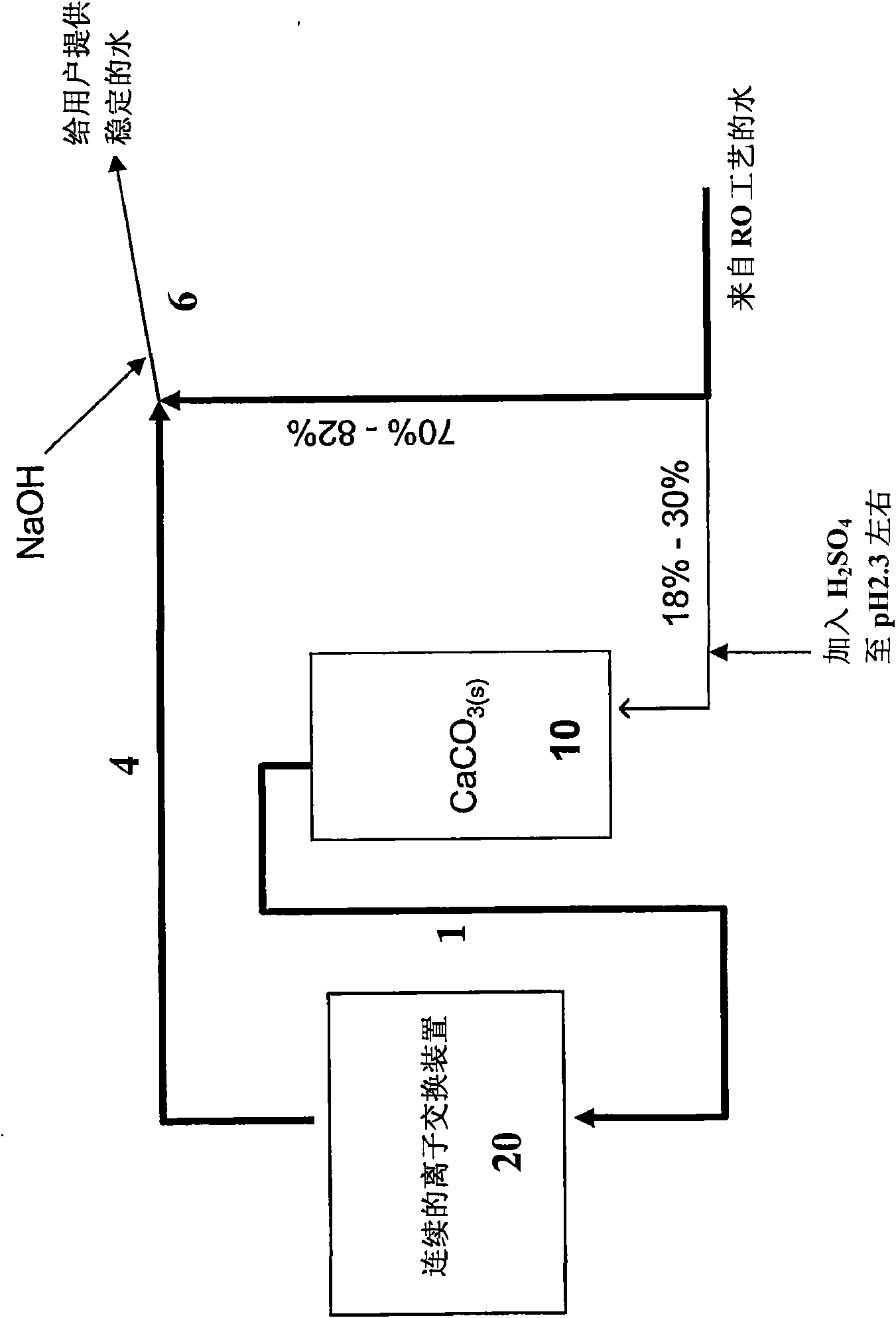

Method used

Image

Examples

Embodiment 1

Embodiment 1 (operation under continuous mode)

[0057] Water quality requirements for post-treatment process outlets

Alkalinity>90mg / L CaCO 3

120>[Ca 2+ ]≥80mg / L CaCO 3

[Mg 2+ ]=24.3mg / L Mg 2+

CCPP≥3.0mg / L CaCO 3

pH=<8.5

General design

[0058] The chemicals that need to be added to the water as it passes through the calcite reactor are (assuming only 25% of the water passes through the calcite reactor, the chemical added per cubic meter of water represents 25% of these values):

h 2 SO 4 (100%)=487mg / L (pH reaches 2.06)

CaCO 3(s) =760mg / L

[0059] According to the existing calcite dissolution method, this water flow should be combined with 75% untreated water and added NaOH to obtain a pH value of about 7.8 to obtain the following results: Alkalinity = 92.5mg / L CaCO 3 , [Ca 2+ ]=190mg / L CaCO 3 , CCPP=3.2mg / L CaCO 3 (NaOH required in this hypothetical case is 21.4 mg / L).

[0060] In the method that the present invention proposes, the water quality...

Embodiment 2

Embodiment 2 (multi-column operation)

[0066] Water quality requirements for post-treatment process outlets

Alkalinity≥65mg / L CaCO 3

120>[Ca 2+ ]≥80mg / L CaCO 3

[Mg 2+ ]=12.15mg / L

CCPP≥2.0mg / L CaCO 3

pH<8.5

General design

[0067] The chemicals that need to be added to the water as it passes through the calcite reactor are (assuming only 25% of the water passes through the calcite reactor, the chemical added to the entire water flow represents a quarter of the dosage stated in this article):

h 2 SO 4 (100%)=316mg / L (pH reaches 2.24)

CaCO 3(s) =525mg / L

[0068] According to the existing calcite dissolution method, this water flow should be combined with 75% untreated water and added NaOH to obtain a pH value of about 8.2 to obtain the following results: Alkalinity = 66mg / L CaCO 3 , [Ca 2+ ]=132mg / L CaCO 3 , CCPP=3.0mg / L CaCO 3 (NaOH dosage required in this case is 12.3 mg / L).

[0069] In the method that the present invention proposes, the water (its...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com