Large-diameter hollow roller and manufacturing method thereof

A hollow roll, large diameter technology, applied in the manufacture of large diameter hollow roll, large diameter hollow roll field, can solve the problems of loss, poor stiffness and strength, inconvenient lifting, etc., to achieve increased stiffness and strength, good balance , The effect of convenient lifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

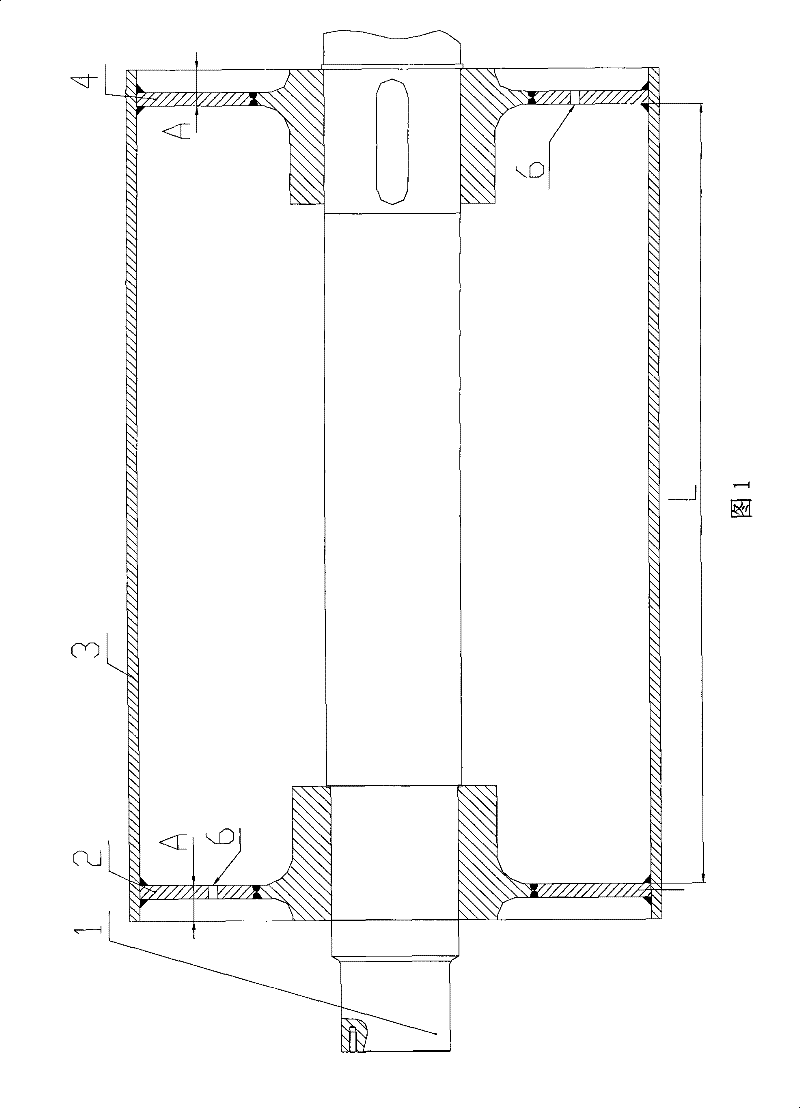

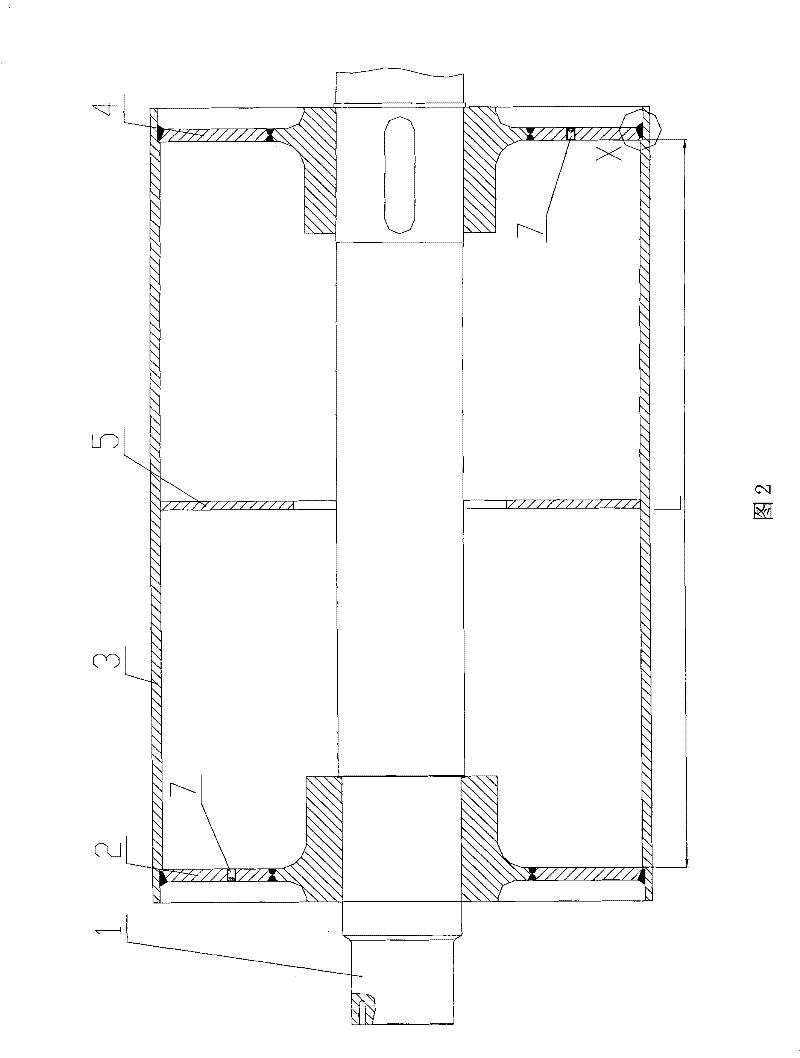

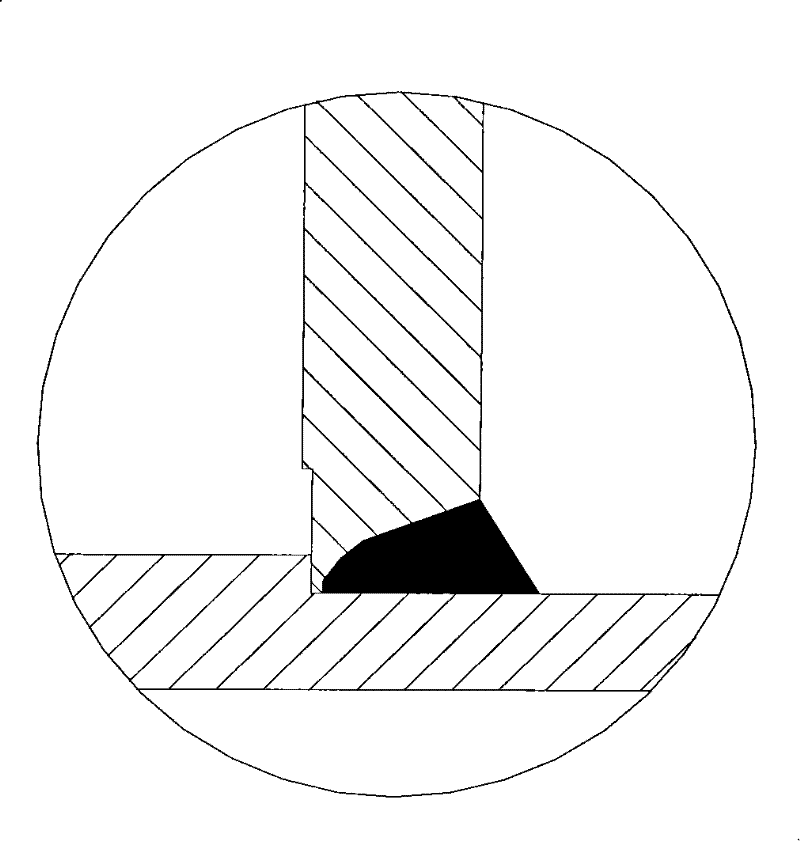

[0030] Such as figure 2 As shown, the large-diameter hollow roll of the present invention (outside diameter greater than 800mm) includes a shaft 1, a left panel 2, a roll body 3, a right panel 4, and a middle panel 5, and the left and right panels 2 and 4 are respectively arranged on the roller body 3. At both ends of the inside, the axis 1 passes through the left and right panels 2, 4, the big end of the axis 1 is on the right, and the small end is on the left; the middle panel 5 is arranged between the left and right panels 2, 4. The shaft 1 passes through the through hole in the center of the middle web 5 , the inner diameter of the through hole of the middle web 5 is larger than the outer diameter of the shaft 1 , and the middle web 5 is fixed on the inner wall of the roller body 3 . The intermediate web 5 is preferably arranged in the middle of the roll body 3 .

[0031] Three M20 or M24 threaded holes are evenly distributed on the circumference of the left and right pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com