Method for preparing raw material of float glass

A float glass and raw material technology, which is applied in the field of preparation of feldspar-free float glass raw materials, can solve problems such as difficulty in achieving uniform mixing, and achieve the effects of reducing the difficulty of quality control, reducing production costs, and reducing exhaust emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

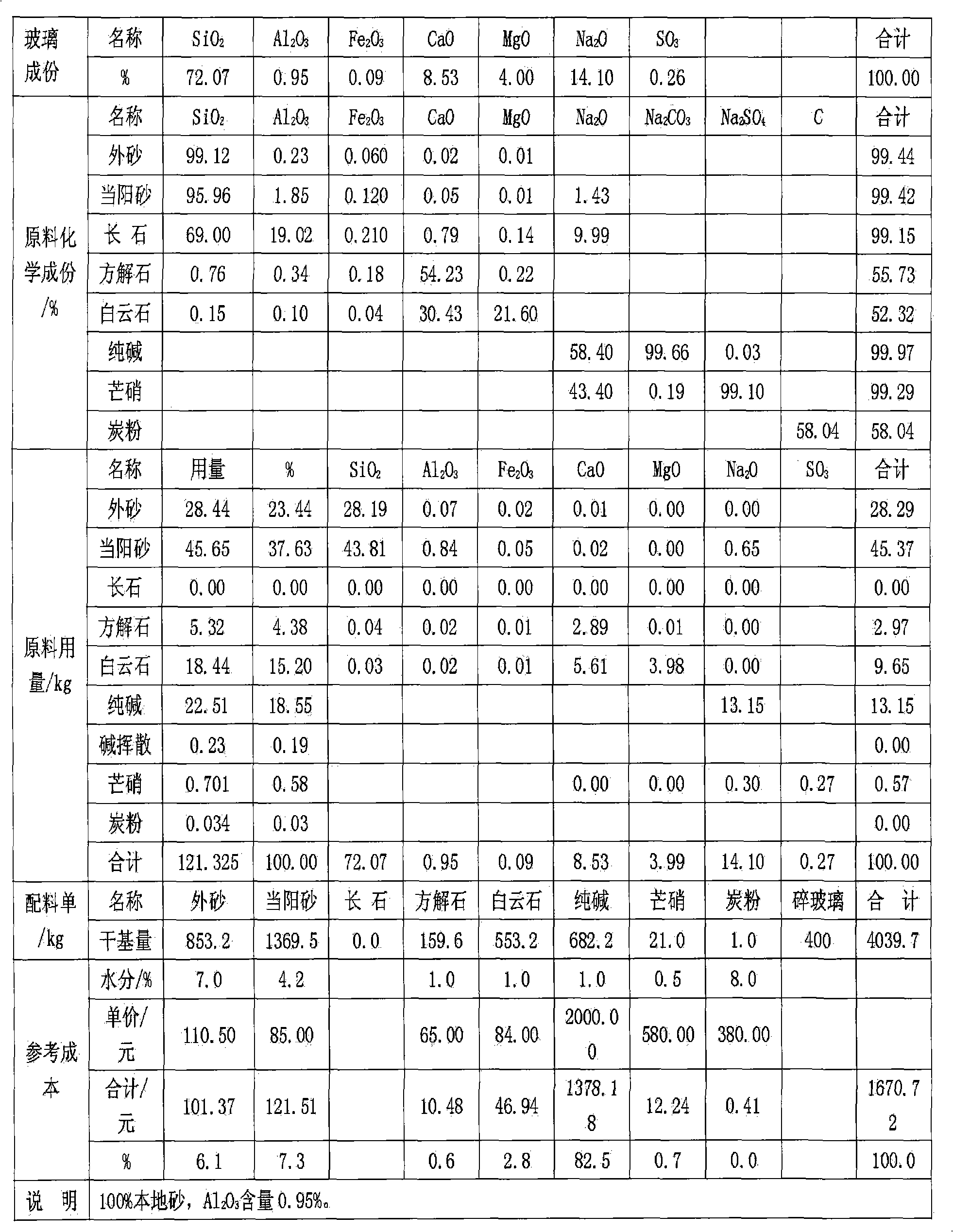

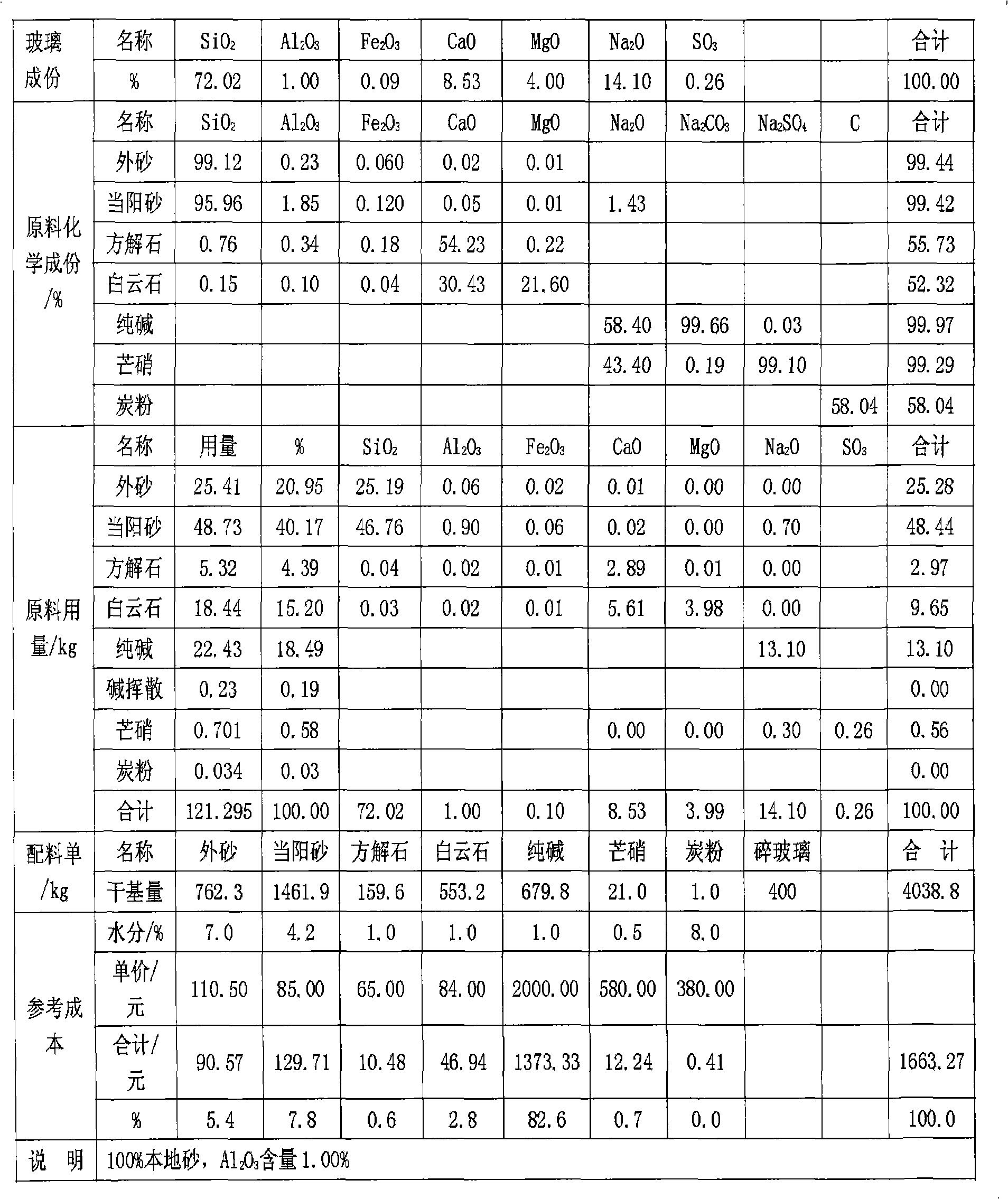

[0023] Dangyang silica sand (local sand for short) chemical composition used in the present invention is as shown in table 3:

[0024] Table 3 Chemical composition of local sand Unit: %

[0025] serial number

SiO 2

al 2 o 3

Fe 2 o 3

CaO

MgO

Na 2 O+K 2 o

total

1

95.96

1.85

0.120

0.05

0.01

1.43

99.42

2

95.91

1.91

0.120

0.08

0.01

1.43

99.46

3

96.04

1.9

0.120

0.08

0.01

1.43

99.58

[0026] Local silica sand particle grade

[0027] >0.8mm=0.10%; 0.8-0.5mm=0.50%; 0.5-0.3mm=39.90%;

[0028] 0.3-0.1mm = 49.80%; <0.1mm = 9.40%;

[0029] Al in local silica sand 2 o 3 Evenly distributed in SiO in the form of potassium feldspar 2 In the particle composition, the content of potassium and sodium is higher than that of foreign silica sand, and the melting temperature is lower than...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com