Laser cutting head and laser embroidery all-in-one machine using same

A laser cutting head and cutting head technology, applied in the direction of automatically controlled embroidery machine, embroidery machine, embroidery machine mechanism, etc., can solve the problems of high cost, edge collision of embroidery frame, poor smoking effect, etc., and achieve low cost and weight. Light, avoid the incomplete effect of smoking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

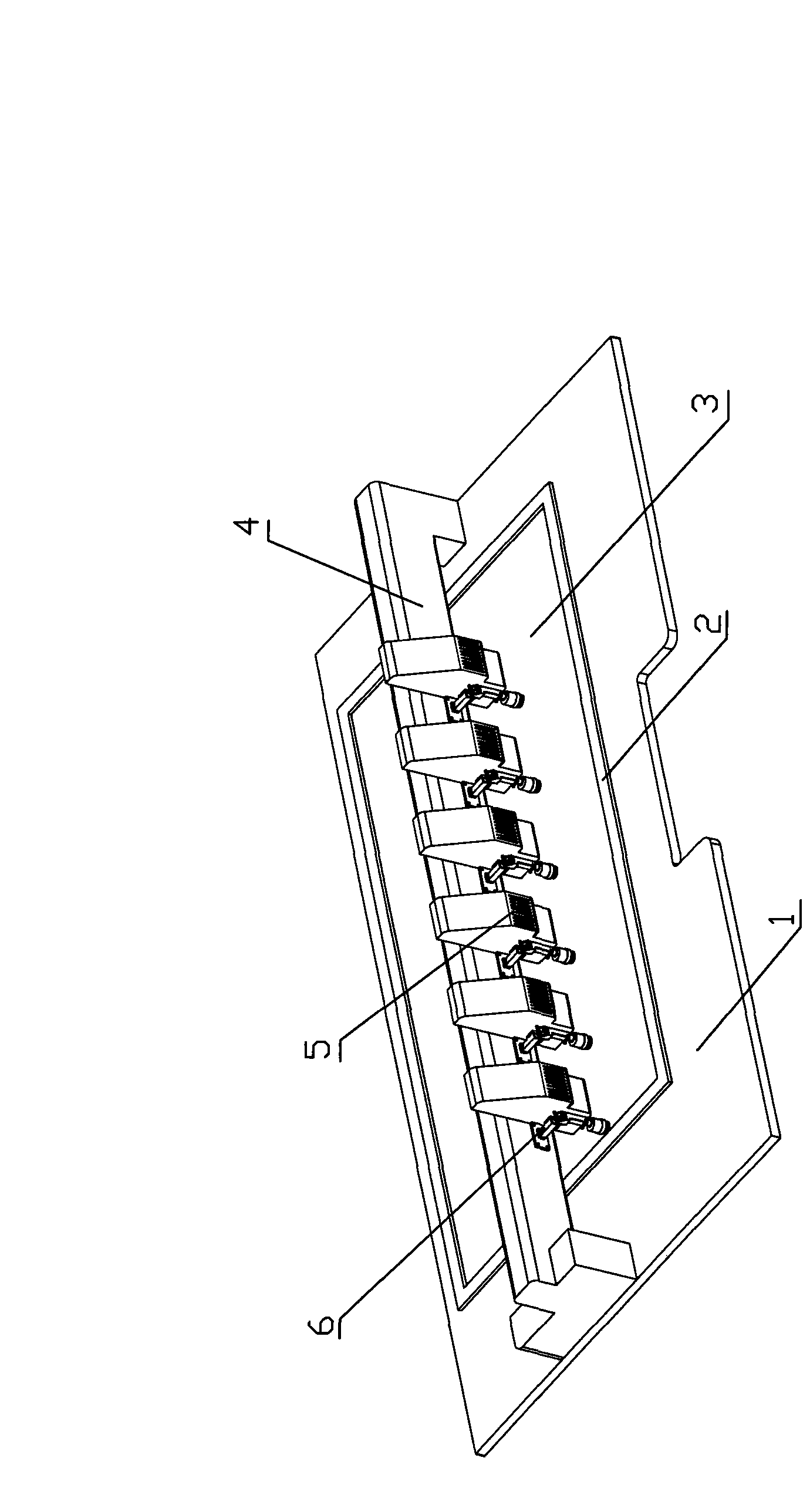

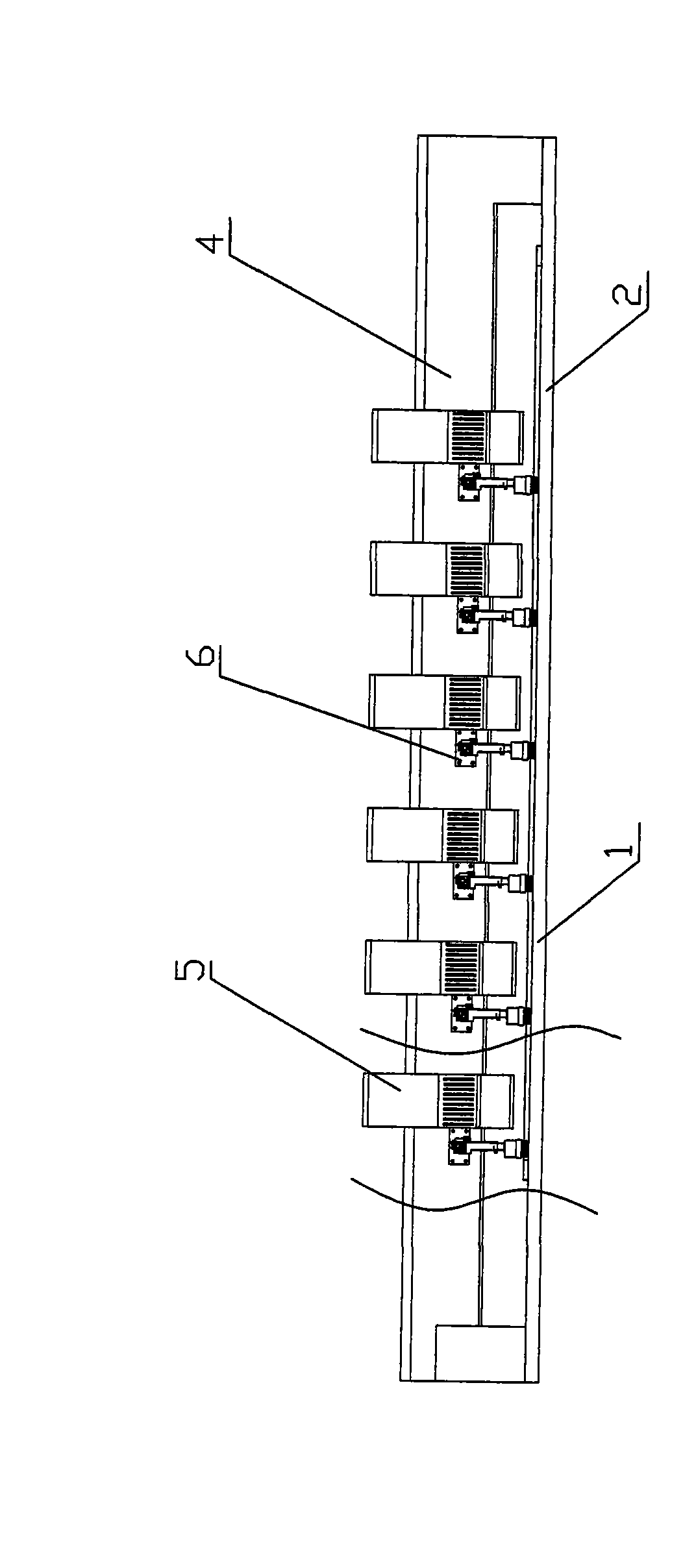

[0022] The present invention will be further explained below in conjunction with the drawings, please refer to figure 1 and figure 2 . It includes a horizontal workbench 1 on which a movable frame 2 is arranged. The frame 2 encloses an area 3 to be processed. The textile to be processed can be fixed in the frame 2. One is set on the worktable 2 and straddles the beam 4 at both ends of the frame body 2. A number of embroidery machines 5 and laser cutting heads 6 are arranged on the beam 4, and the embroidery machine 5 and the laser cutting head 6 are arranged adjacent to the beam 2 on.

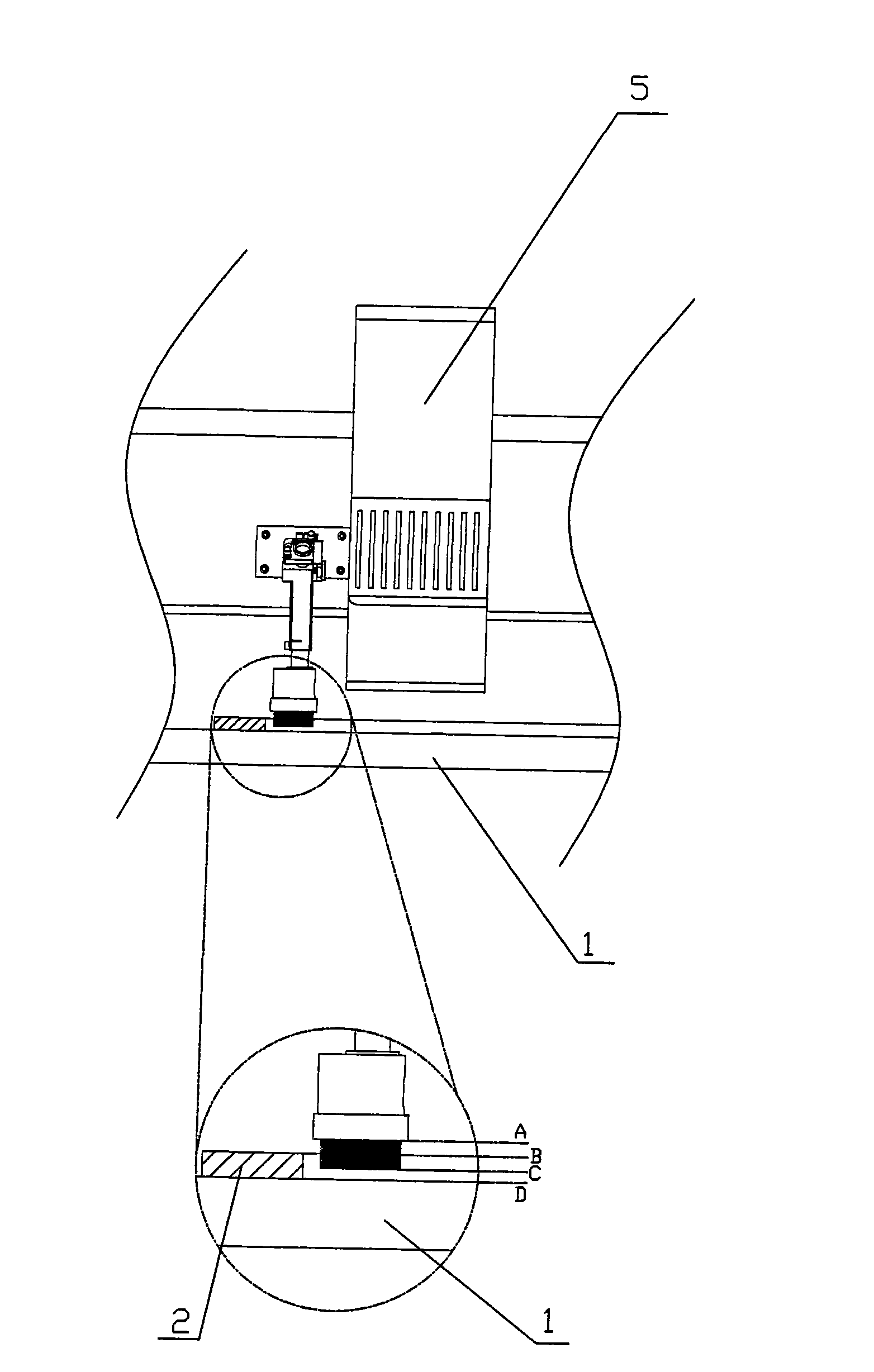

[0023] Please refer to Figure 4 to Figure 6 The laser cutting head 6 includes a substrate 61 connected to the beam 5, and the substrate 61 is fixed on the beam 5 by screws. A connecting rod 62 is vertically fixed on the substrate 61, and a circular through hole is provided in the middle of the connecting rod, and the through hole is used for laser transmission. One end of a connecting member ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com