Method for reinforcing and sealing coal mine and preventing gas

A gas and coal mine technology, applied in the field of coal mine reinforcement and airtight gas prevention and control, can solve problems such as air leakage and gas gushing out, achieve the effects of improving overall strength, preventing corrosion reaction, and ensuring long-term stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

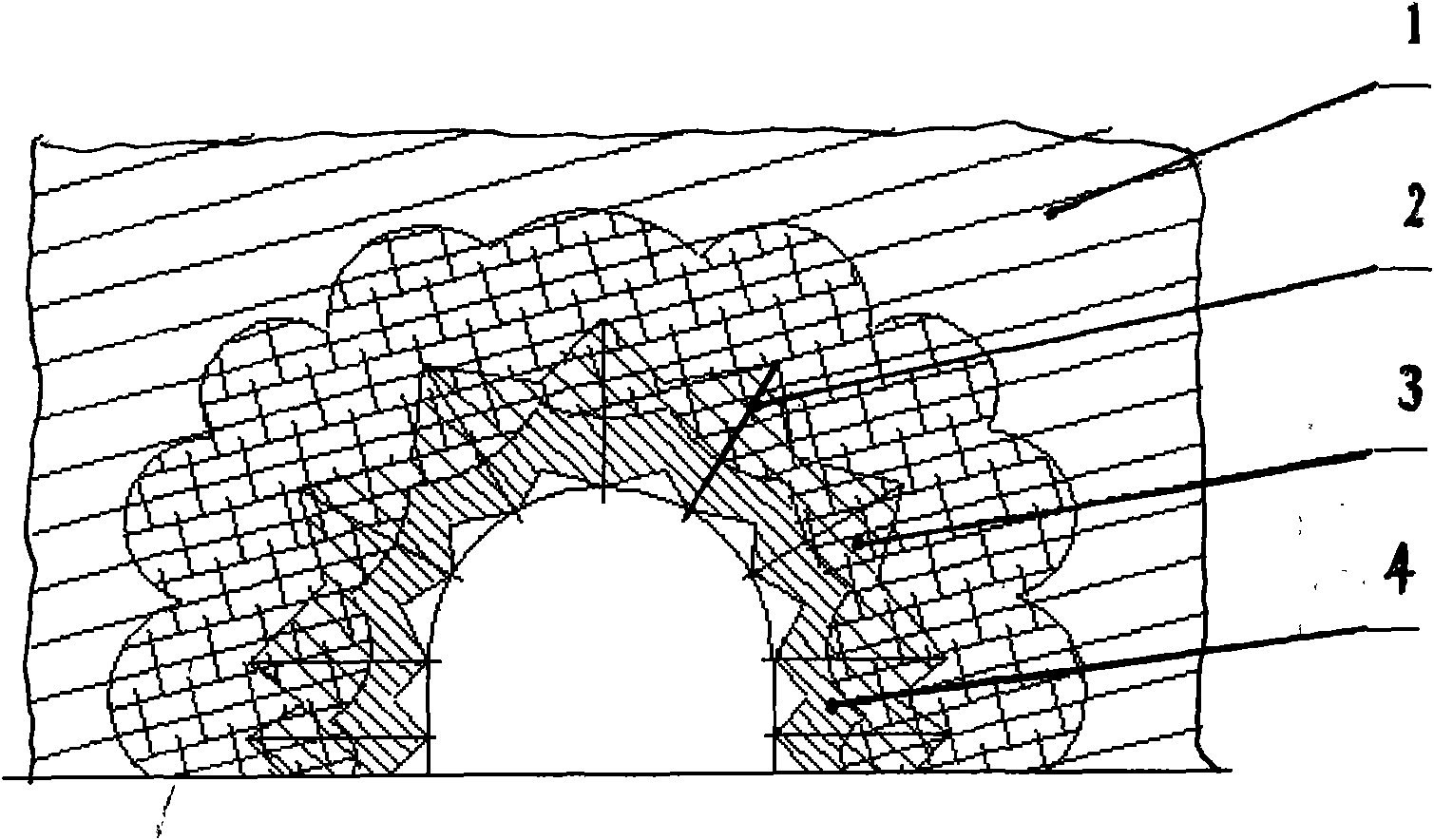

[0019] The object of implementation of the present invention is the following four airtight walls of the mine

[0020] Site overview: ①11301 上 Into the shelf Yokogawa, ②11212 下 Hengchuan, ③ end of Lane 92230 and ④ 8212 下 The four seals of the alley are all built of stone, 0.5 meters thick, the depth of the two side grooves is 0.5-0.8 meters, and the cross-section is 10-15 square meters. ①11301 上 Into the shelf Yokogawa, ②11212 下 The airtight walls of Hengchuan are basically intact, but the ventilation negative pressure is relatively large, and the air leakage to the outside is serious. CH 4 up to 1.3%, the roadway is supported by I-beams and wooden sheds, and the direct roof is siltstone, which is basically complete; # In the coal seam, the immediate top is K 4 Limestone, relatively complete; ④8212 下 Roadway closed, CH 4 : 0.2%, CO 2 : 17%. The roadway is supported by I-shaped steel, and the direct roof is siltstone, the roof is relatively broken, and the roof is ser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com