Pneumatic nozzle of variable geometry turbocharger (VGT)

A technology of turbocharger and pneumatic nozzle, applied in the field of turbocharger nozzle and pneumatic nozzle, can solve the problems of poor effect, small exhaust flow, unfavorable exhaust pressure, etc., so as to improve the response characteristics and increase the supercharging ratio. , Efficient matching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

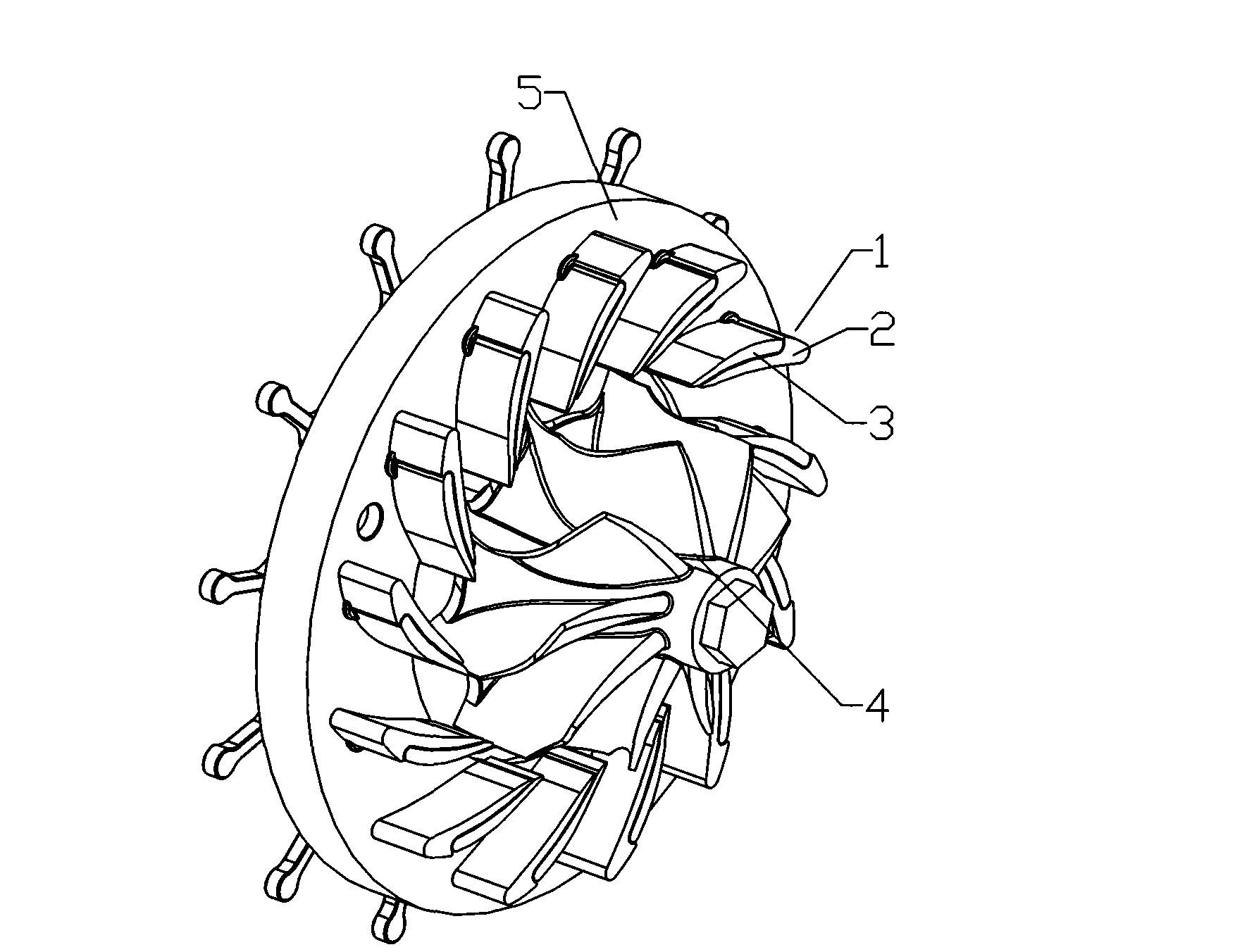

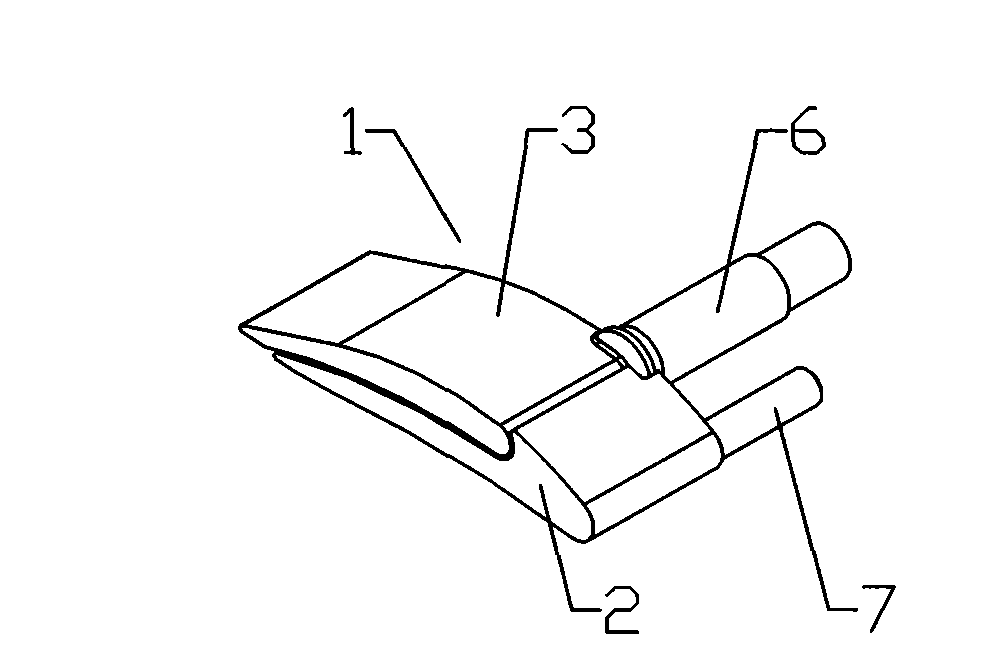

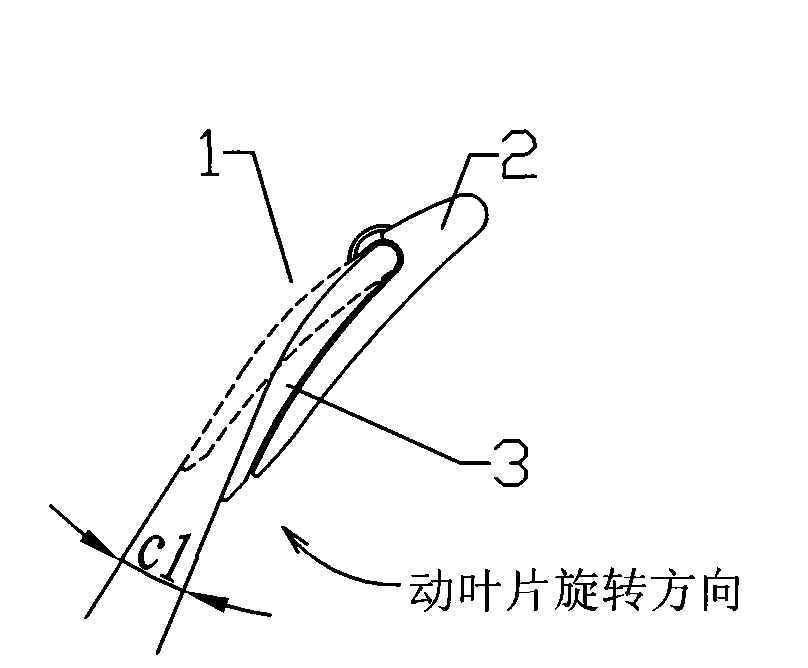

[0028] Example: such as Figure 4 , Figure 5 with Image 6 As shown, the aerodynamic nozzle of the variable geometry turbocharger includes an aerodynamic nozzle support plate 8 and a power turbine 15 coaxially connected with the aerodynamic nozzle support plate 8, and the aerodynamic nozzle support plate 8 is arranged on the surface of the power turbine 15 side There are thirteen pneumatic nozzle blades 12. The shape of the pneumatic nozzle blades 12 is arc-shaped. On the other surface of the pneumatic nozzle support plate 8, a shift fork plate 10 is arranged. The shift fork 11 is provided, the pneumatic nozzle blade 12 includes the pneumatic nozzle moving blade 13 and the pneumatic nozzle stationary blade 14, the pneumatic nozzle moving blade 13 includes an outer arc surface 131 and an inner arc surface 132, and the inner arc surface 132 forms a groove 24, the pneumatic nozzle The nozzle stationary vane 14 is located in the groove 24, the surface matching the pneumatic noz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com