Decohering and shimming device

A guiding device and laser beam technology, applied in the laser field, can solve the problems of many system components, high installation accuracy requirements, low laser utilization rate, etc., and achieve the effect of small occupied volume and high laser utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

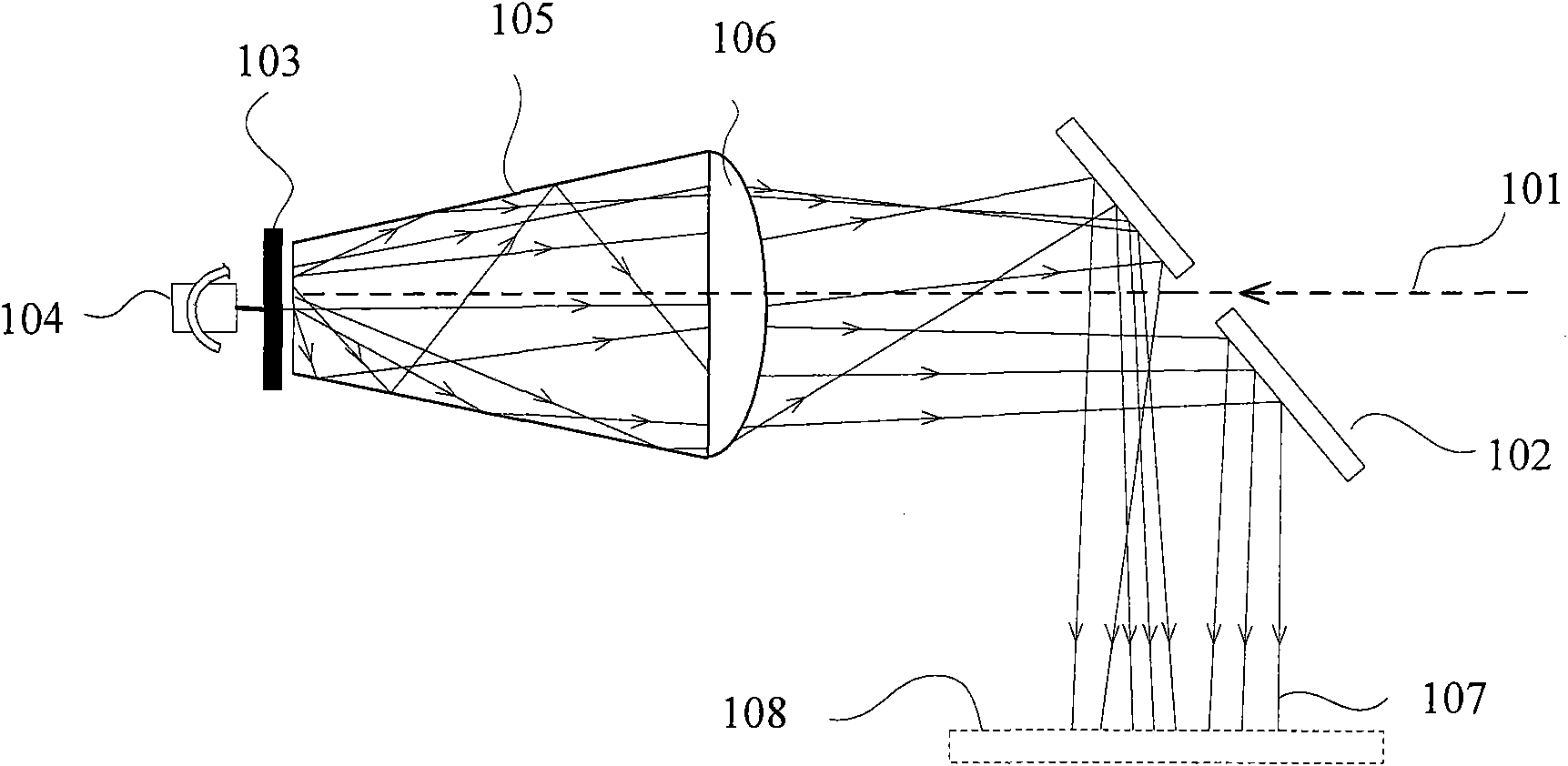

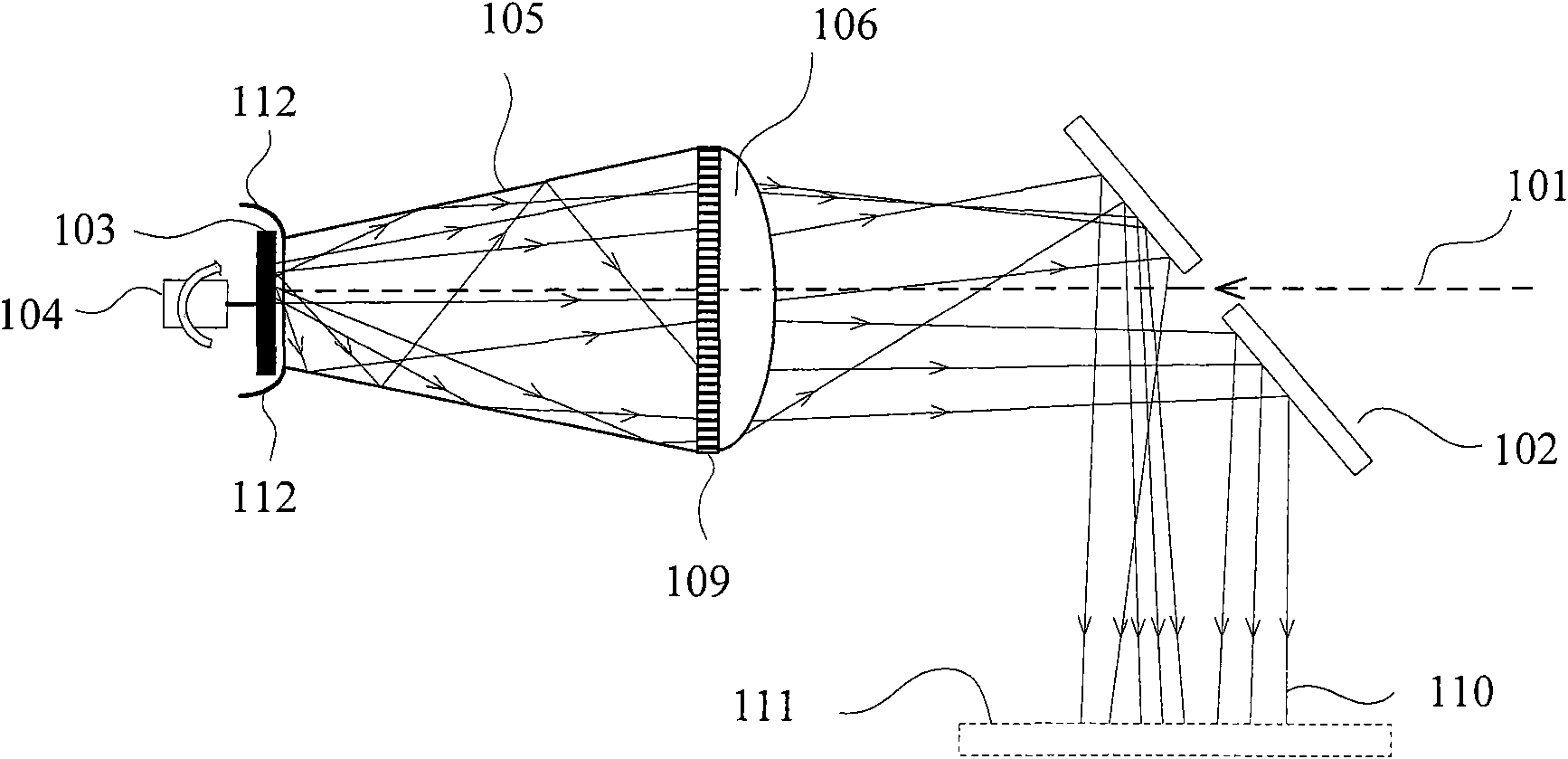

[0034] Figure 1A It is a schematic diagram of an embodiment of the present invention. The device in this embodiment includes a perforated reflector 102 , a diffuse reflector 103 , a motor 104 that rotates the diffuse reflector 103 , a total reflection cavity 105 and a free-form surface lens 106 .

[0035] The structure of the device of the present invention in this embodiment will be described in detail below. In this embodiment, a perforated reflector 102 (the perforated reflector of this structure is disclosed in the utility model patent of application number CN200720305226.8) is used to guide the coherent incident laser beam 101 into the total reflection cavity 105, in order to To minimize the impact of the apertured reflector 102 on the optical path, the size of the aperture on the apertured reflector 102 should be as small as possible, and may only be slightly larger than the beam diameter of the beam 101 . In this embodiment, the total reflection cavity 105 adopts a hol...

Embodiment 2

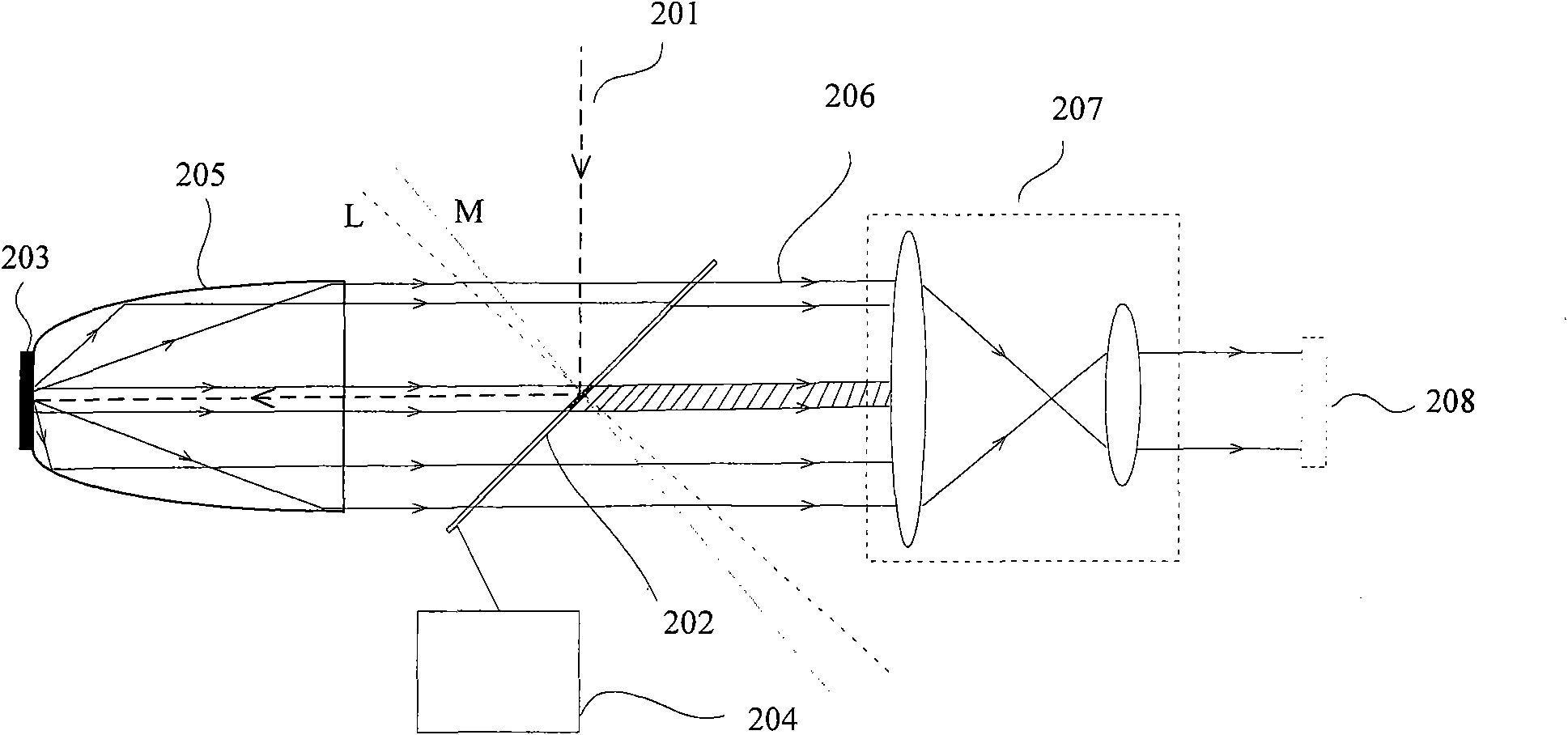

[0041] figure 2 It is a schematic diagram of another embodiment of the present invention. In this embodiment, a partial reflector 202 is used to guide the coherent incident laser beam 201 into the total reflection cavity 205. The reflective part of the partial reflector 202 is coated with a high-reflection film for the wavelength of the beam 201, and the transmissive part of the partial reflector 202 is coated with For the anti-reflection coating of the wavelength of the light beam 201, the partial reflection mirror 202 of this new structure is used because its size can completely accept all the light beams in the optical path, so that the fixing device of the partial reflection mirror 202 does not need to appear in the optical path. There is no interference in the light path. The normal of the beam 201 on the partial reflector 202 is the L axis, the M axis passes through the incident point of the beam 201 on the partial reflector 202 and slightly deviates from the L axis by...

Embodiment 3

[0047] image 3 for will Figure 1A The setup shown in is a schematic diagram of a monolithic DLP projection system. In this embodiment, the three-primary-color laser light source is composed of a red laser 301 , a green laser 302 and a blue laser 303 , and emits coherent red light 321 , green light 322 and blue light 323 respectively. The red light 321 , green light 322 , and blue light 323 time-divisionally multiplexed through the holes of the perforated mirror 305 , and are incident on the diffuse reflection plate 306 through the free-form surface lens 309 , and the diffuse reflection plate 306 is rotated by the motor 307 . The inner wall of the total reflection cavity 308 is coated with a thin film for total reflection of the red light 321, the green light 322, and the blue light 323, and the three primary color lasers are respectively processed by the diffuse reflection plate 306, the total reflection cavity 308 and the free-form surface lens 309 to form incoherent light ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com