Metal bump structure and application thereof to packaging structure

A technology of metal bumps and packaging structures, which is applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of complex manufacturing process, high cost, poor lamination of conductive particles of anisotropic conductive film, etc., and achieve improved capture rate, The effect of reducing churn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

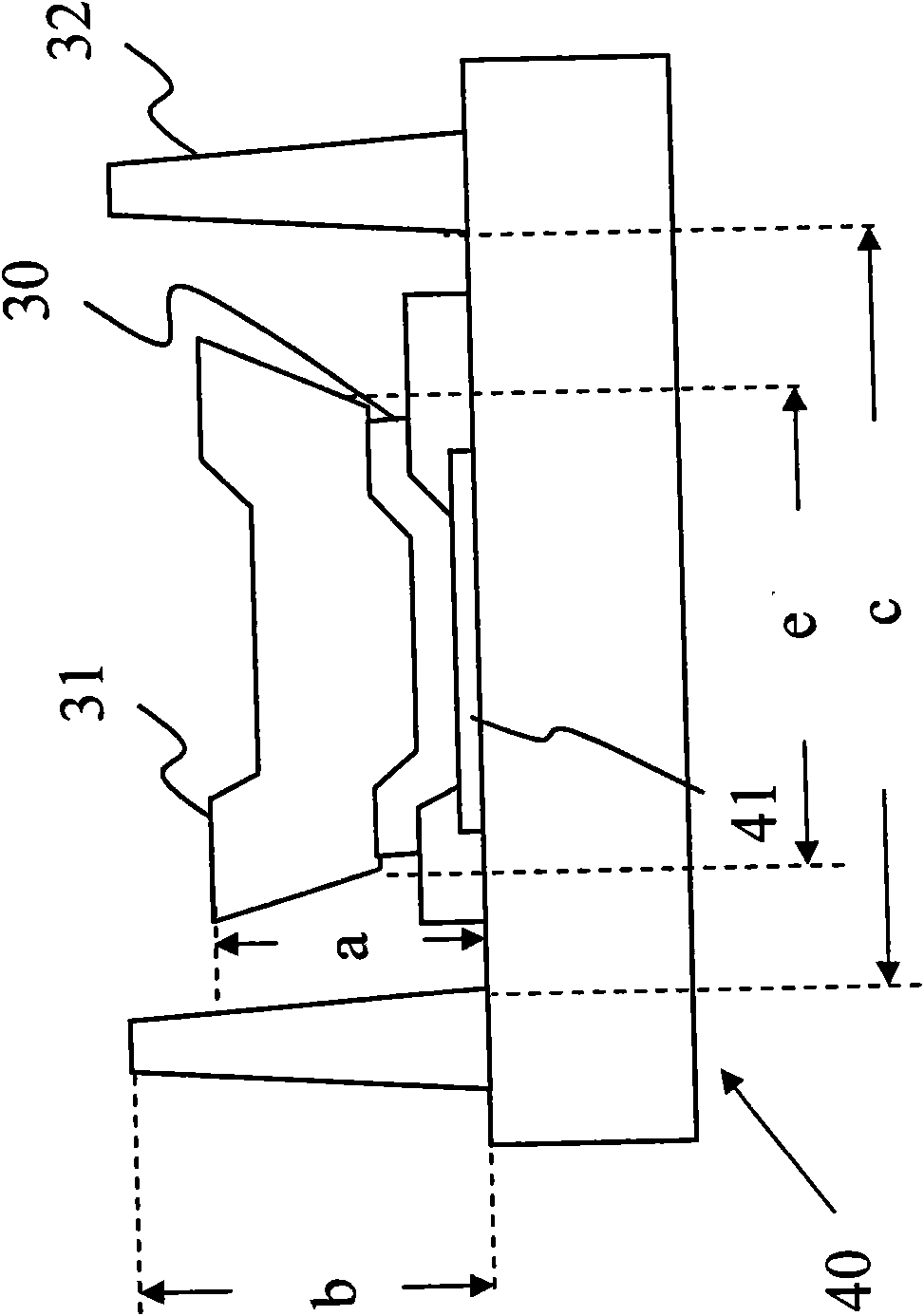

[0046] Please refer to Figure 3A and Figure 3B , are respectively a cross-sectional view and a top view of the metal bump structure provided by the embodiment of the present invention. The metal bump structure mainly includes an under bump metallurgy (UBM) 30 , a metal bump 31 and a barrier layer (dam structure) 32 , wherein the UBM layer 30 is disposed on the connection pad 41 of the semiconductor device 40 and the metal bump 31, and the barrier layer 32 is made of polymer material on the semiconductor element 40, and the barrier layer 32 completely surrounds the metal bump 31, wherein the height b of the barrier layer 32 exceeds The height a of the metal bump 31, such as Figure 3A b>a shown, and the barrier layer 32 is not in contact with the metal bump 31, that is, there is a gap between the barrier layer 32 and the metal bump 31, as Figure 3A c > e shown.

[0047] Please refer to Figure 4A to Figure 4F , the entire process of fabricating the metal bump structure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com