Mothproof veneer board, mothproof faced veneer board and manufacturing method thereof

A technology for veneer plywood and a manufacturing method, applied in the field of plywood, can solve problems such as the reduction of insect-proof performance, and achieve the effects of prolonging service life, non-volatile and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

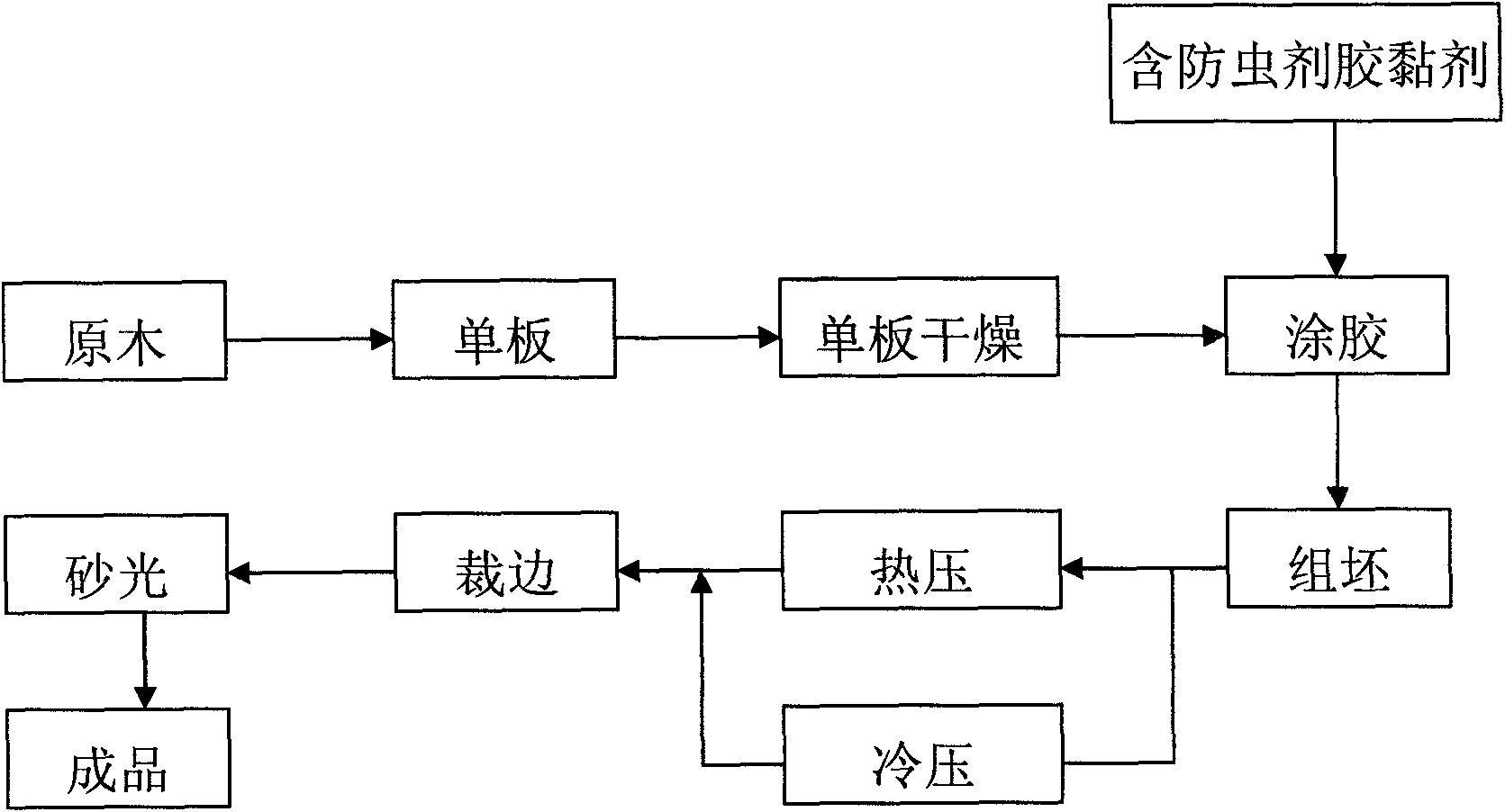

Method used

Image

Examples

Embodiment 1

[0029] 1. The phenthrin insect repellant is made into microcapsules for standby use, and the mass percentage of solids is 10-20%.

[0030] 2. Drying, splicing and repairing of poplar, eucalyptus or other types of veneer by rotary cutting and slicing, and grouping according to the requirements of plywood forming.

[0031] 3. The glue mixing ratio is: adhesive 100Kg, flour 20±2Kg, insect repellant 0.15Kg, ammonium chloride 1±0.1Kg. The adhesive is modified urea-formaldehyde resin glue or phenolic resin glue.

[0032] 4. After the repair, the veneer is glued, assembled and pre-pressed according to the requirements of plywood assembly. The amount of glue applied on both sides of the veneer is 300g / m 2 , the pre-pressing pressure is 0.7Mpa, the pre-pressing time is 0.5h, and the hot-pressing temperature is 110±5°C.

[0033] 5. After pre-pressing, the surface of the slab is repaired, the slab is hot-pressed, cured, and sanded to form a plywood slab. Hot pressing pressure 0.5Mpa,...

Embodiment 2

[0041] 1. The cypermethrin insect repellant is made into microcapsules for standby use, and the mass percentage of solids is 10-20%.

[0042] 2. Drying, splicing and repairing of poplar, eucalyptus or other types of veneer by rotary cutting and slicing, and grouping according to the requirements of plywood forming.

[0043]3. The glue mixing ratio is: adhesive 100Kg, flour 20±2Kg, insect repellant 0.5Kg, ammonium chloride 1±0.1Kg. The adhesive is modified urea-formaldehyde resin glue or melamine resin glue.

[0044] 4. After the repair, the veneer is glued, assembled and pre-pressed according to the requirements of plywood assembly. The amount of glue applied on both sides of the veneer is 350g / m 2 , the pre-pressing pressure is 0.8Mpa, the pre-pressing time is 1.5h, and the hot-pressing temperature is 110±5℃.

[0045] 5. After pre-pressing, the surface of the slab is repaired, the slab is hot-pressed, cured, and sanded to form a plywood slab (also called a substrate). Hot...

Embodiment 3

[0053] 1. The fenvalerate insect repellent is made into microcapsules for standby use, and the mass percentage of solids is 10-20%.

[0054] 2. Drying, splicing and repairing of poplar, eucalyptus or other types of veneer by rotary cutting and slicing, and grouping according to the requirements of plywood forming.

[0055] 3. The glue mixing ratio is: adhesive 100Kg, flour 20±2Kg, insect repellent 1.0Kg, ammonium chloride 1±0.1Kg. The adhesive is urea-formaldehyde resin glue or soybean adhesive.

[0056] 4. After the repair, the veneer is glued, assembled and pre-pressed according to the requirements of plywood assembly. The amount of glue applied on both sides of the veneer is 400g / m 2 , The pre-pressing pressure is 0.9Mpa, the pre-pressing time is 3.0h, and the hot-pressing temperature is 110±5°C.

[0057] 5. After pre-pressing, the surface of the slab is repaired, the slab is hot-pressed, cured, and sanded to form a plywood slab. Hot pressing pressure 1.4Mpa, time 2min / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com