Excimer lamp

A technology of excimer lamps and electrodes, which is applied in the direction of discharge lamps, parts of gas discharge lamps, lighting devices, etc., can solve the problems of wire 116 falling off, lamp failure to light up, and influence, and achieve high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

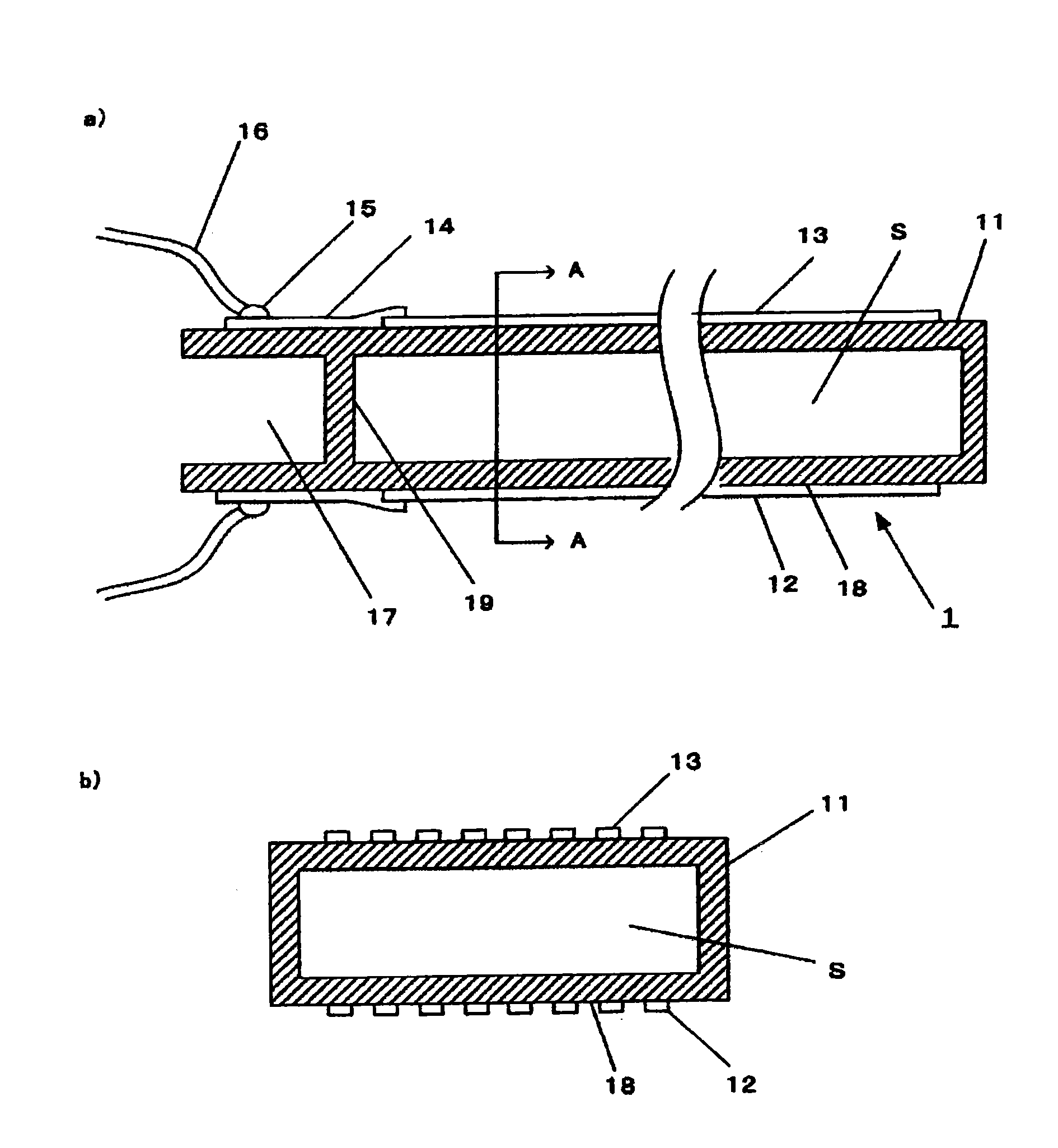

[0050] The first embodiment of the excimer lamp of the present invention is shown in figure 1 . figure 1-a) is a schematic cross-sectional view of the excimer lamp 1 of the present invention cut along the tube axis direction. The excimer lamp 1 is composed of a discharge vessel 11 made of quartz glass, an electrode 12 and an electrode 13 formed on the outer surface of the discharge vessel 11 at positions facing each other, and an electrode 13 formed inside the discharge vessel 11 and enclosed with a A discharge space S of gas such as xenon is used for discharge. In addition, although not shown in the figure, in the discharge space S, an ultraviolet reflective film is provided in addition to the window 18 for emitting light. The electrode 12 is made of, for example, a light-transmitting electrode made of grid-shaped printed electrodes, etc., and the surface of the discharge vessel 11 on which the electrode 12 is disposed serves as a window for emitting excimer light generat...

Embodiment 2

[0058] Figure 4 Shows the second embodiment of the present invention. Figure 4 -a) is a schematic cross-sectional view of the excimer lamp 20 according to the second embodiment of the present invention, taken along the axis of the lamp tube. The basic composition of the excimer lamp 20 and figure 1 The case of the first embodiment shown is the same, and the same reference numerals are assigned to the same components as in the case of the first embodiment. And, with figure 1 In the same manner as in the case of , an ultraviolet reflective film (not shown) is provided in the discharge space S. As shown in FIG. In this second embodiment, the space 21 connected to the discharge space S and divided by at least five surfaces is isolated from the outside by the outer wall 22 . In this embodiment, the interior of the space 21 is in a vacuum state, or is filled with a gas that is not easy to discharge, such as nitrogen. Accordingly, there is an advantage that no discharge occu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com