Method for extracting flavonoid compounds in mung bean hull

A technology for extracting flavonoids in the skin, which is applied in the directions of organic chemistry, pharmaceutical formulations, plant raw materials, etc., can solve the problems of low efficiency, unsuitable for industrial production, long extraction time, etc., and achieves high efficiency, simple production, and long extraction time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

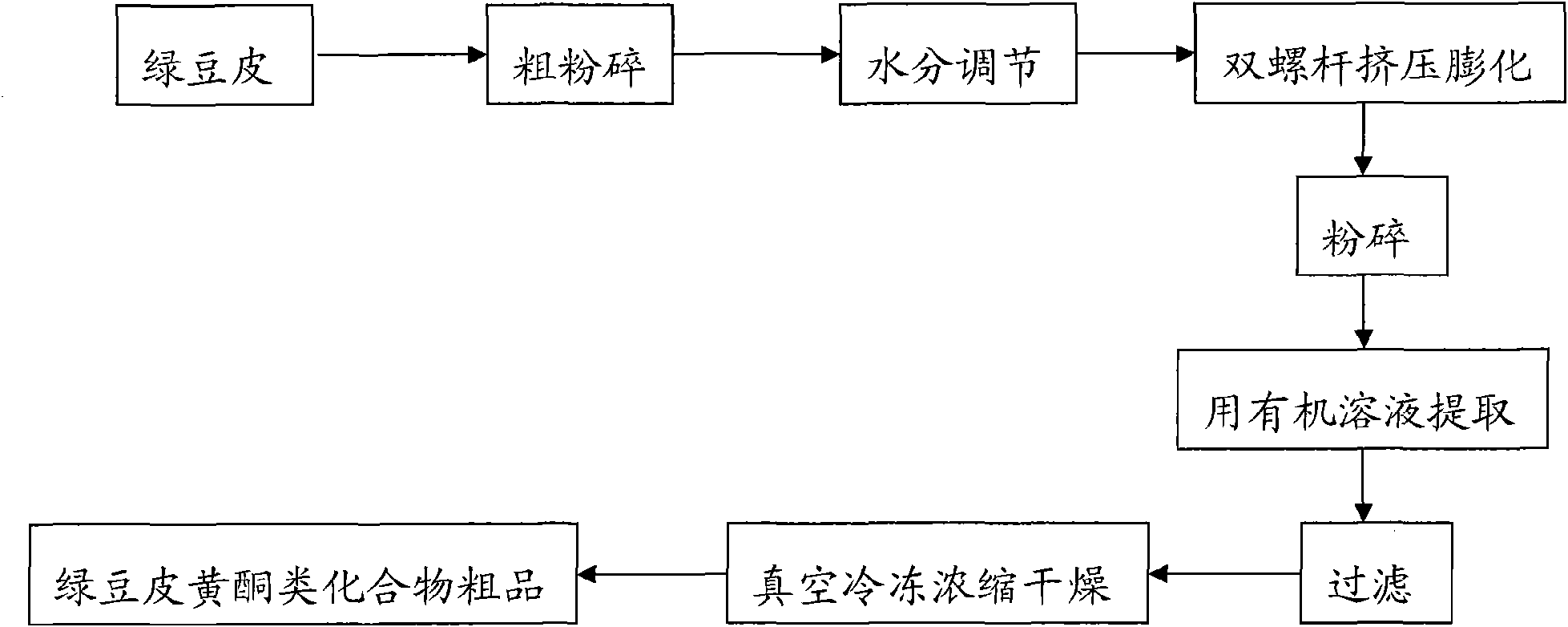

Method used

Image

Examples

Embodiment 1

[0020] First, collect 1kg of mung bean skins, coarsely crush and pass through a 20-mesh sieve, and then adjust the moisture content of mung bean skins to 15%. Subsequently, the mung bean skin powder with adjusted moisture content is subjected to twin-screw extrusion expansion treatment: extrusion temperature is 110°C, screw speed is 200r / min, and feeding speed is 500g / min, so that the mung bean skin powder becomes porous with loose texture status. Then, it was pulverized to 40 mesh using a plant pulverizer. Afterwards, 10 g of mung bean skin powder was weighed and poured into a beaker, and 200 mL of 40% ethanol solution was added for extraction, and the extraction was carried out at a temperature of 80° C. for 2 h. Finally, the filtrate was obtained by filtration, and the filtrate was divided into trays with a large open area, and subjected to vacuum freeze concentration and drying at 30° C. for 8 hours to obtain crude mung bean peel flavonoids.

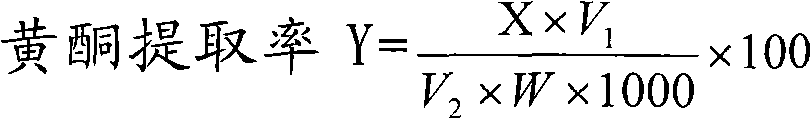

[0021] Determination: Using...

Embodiment 2

[0037] First, collect 1.5kg of mung bean skins, coarsely crush and pass through a 20-mesh sieve, and then adjust the moisture content of mung bean skins to 17%. Subsequently, the coarse mung bean skin powder with moisture adjustment is subjected to twin-screw extrusion expansion treatment: the extrusion temperature is 115°C, the screw speed is 270r / min, and the feeding speed is 700g / min, so that the mung bean skin coarse powder becomes porous with loose texture. status. Then, the extruded product was pulverized to 40 mesh using a plant pulverizer. Afterwards, 10 g of mung bean skin powder was weighed and poured into a glass beaker, and 250 ml of 40% ethanol solution was added for extraction, and the extraction was carried out at a temperature of 75° C. for 2.5 h. Finally, the filtrate was obtained by filtration, and the filtrate was divided into trays with a large open area, and subjected to vacuum freeze concentration and drying at 45° C. for 6 hours to obtain crude mung bea...

Embodiment 3

[0040] First, collect 2kg of mung bean skins, coarsely crush and pass through a 20-mesh sieve, and then adjust the moisture content of mung bean skins to 18%. Subsequently, the mung bean skin with adjusted moisture content is subjected to twin-screw extrusion expansion treatment: extrusion temperature 120°C, screw speed 250r / min, feeding speed 600g / min, so that the mung bean skin powder becomes a loose texture porous state. Then, the extruded product was pulverized to 40 mesh using a plant pulverizer. Afterwards, 10 g was weighed and poured into a glass beaker, and 300 ml of 35% ethanol solution was added for extraction, and the extraction was carried out at a temperature of 80° C. for 3 hours. Finally, the filtrate was obtained by filtration, and the filtrate was divided into trays with a larger open area, and subjected to vacuum freeze concentration and drying at 50° C. for 5 hours to obtain crude mung bean peel flavonoids.

[0041] The determination method is the same as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com