Concentration technology for zymogen liquid

A fermenting bacteria and process technology, applied in tissue cell/virus culture devices, biochemical instruments, semi-permeable membrane separation, etc., can solve problems such as difficult continuous production, low bacteria collection rate, and low production efficiency, and achieve production High efficiency, high concentration efficiency, and less maintenance and repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

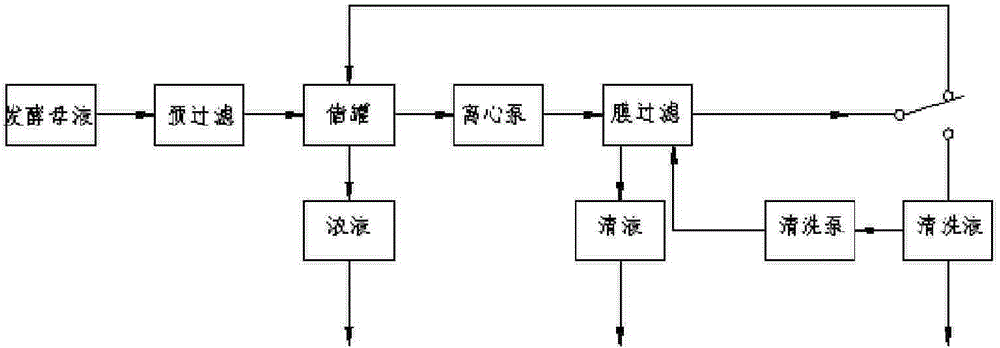

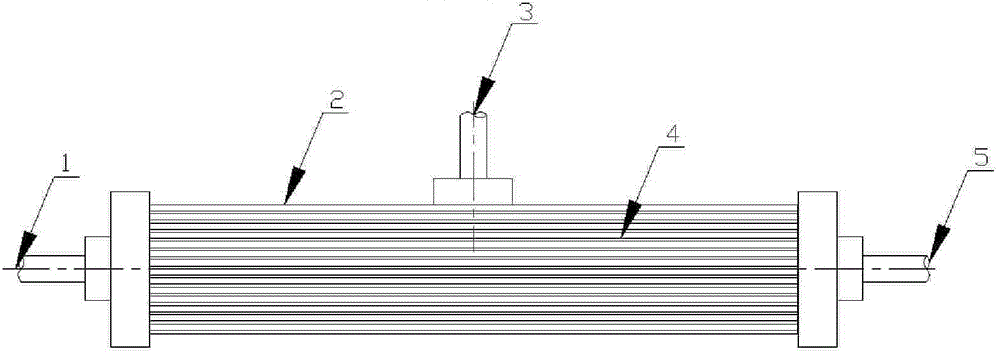

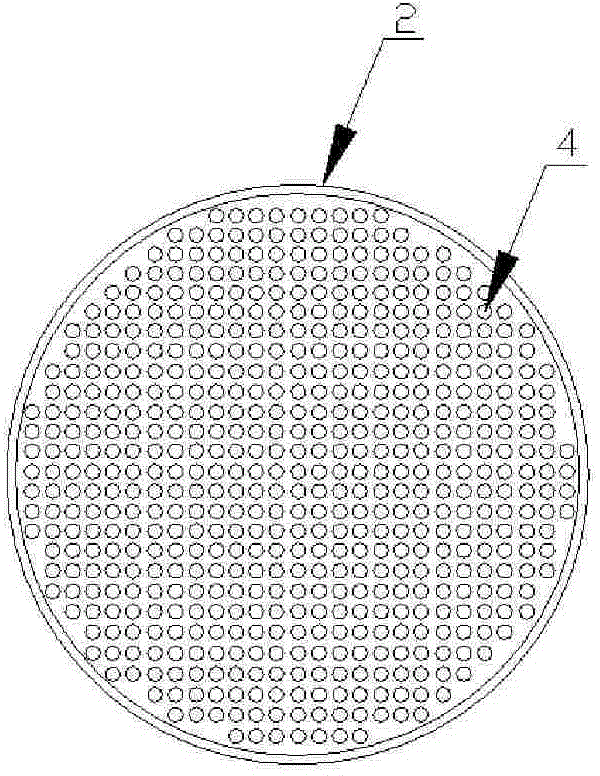

[0015] see figure 1 , figure 2 with image 3 , the operating process of the present invention is as follows:

[0016] The fermented bacteria liquid first goes through a pre-filtering treatment process, and firstly removes particles larger than 1 mm in the fermented bacteria liquid before entering the storage tank; then the fermented bacteria liquid in the storage tank enters from the entrance 1 of the membrane processor 2, The outlet 5 of the membrane processor 2 flows out, and the membrane processor 2 is a high molecular polyacrylonitrile fiber hollow membrane filter tube combination equipment. The high molecular polyacrylonitrile fiber hollow membrane filter tube combination equipment is assembled with numerous diameters of 2-3 mm, The fiber membrane tube 4 with a molecular weight of 40,000-80,000, the overall diameter of the fiber membrane tube 4 is 12-18cm, and the length is 90-110cm. If it exists, part of the fermentation liquid seeps out the clear liquid through the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com