GCr15 bearing steel bloom continuous casting dynamic soft reduction process

A light-reduction, bearing steel technology, used in metal rolling and other directions, can solve the problems of inability to adjust the stirring position, limiting the realization of the process, and strong crack sensitivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: Bearing steel GCr15 continuous casting bloom The bloom section size is 280mm * 325mm, and the main chemical composition (%) of the pouring heat is shown in the following table:

[0025] C

Si

mn

P

S

Cr

0.98

0.24

0.29

0.008

0.008

1.45

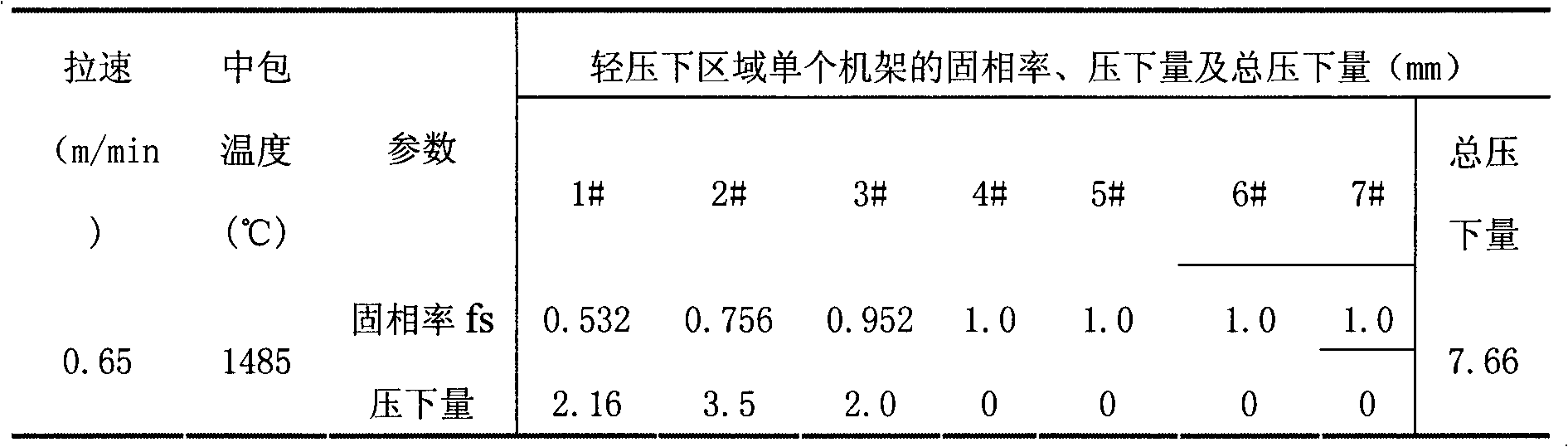

[0026] The main process parameters of pouring heat continuous casting are shown in the table below:

[0027]

Embodiment 2

[0028] Embodiment 2: The section size of bearing steel GCr15 continuous casting bloom is 280mm * 325mm, and the main chemical composition (%) of pouring heat is shown in the following table:

[0029] C

Si

mn

P

S

Cr

0.97

0.24

0.28

0.008

0.006

1.45

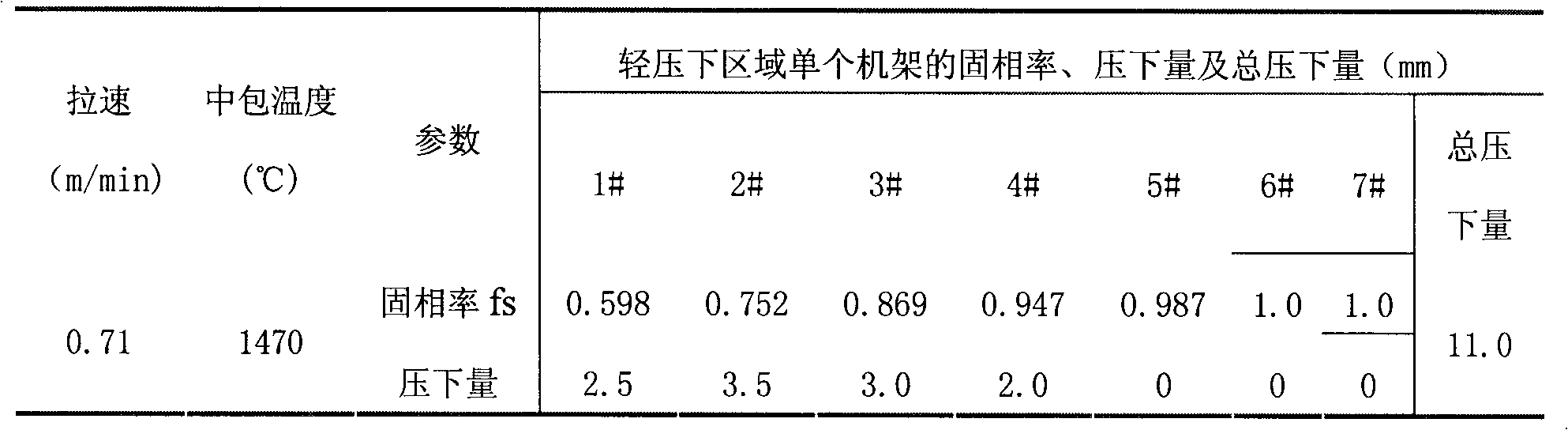

[0030] The main process parameters of pouring heat continuous casting are shown in the table below:

[0031]

Embodiment 3

[0032] Embodiment 3: the section size of bearing steel GCr15 continuous casting bloom is 280mm * 325mm, and the main chemical composition (%) of pouring heat is shown in the following table:

[0033] C

Si

mn

P

S

Cr

0.99

0.23

0.29

0.007

0.005

1.45

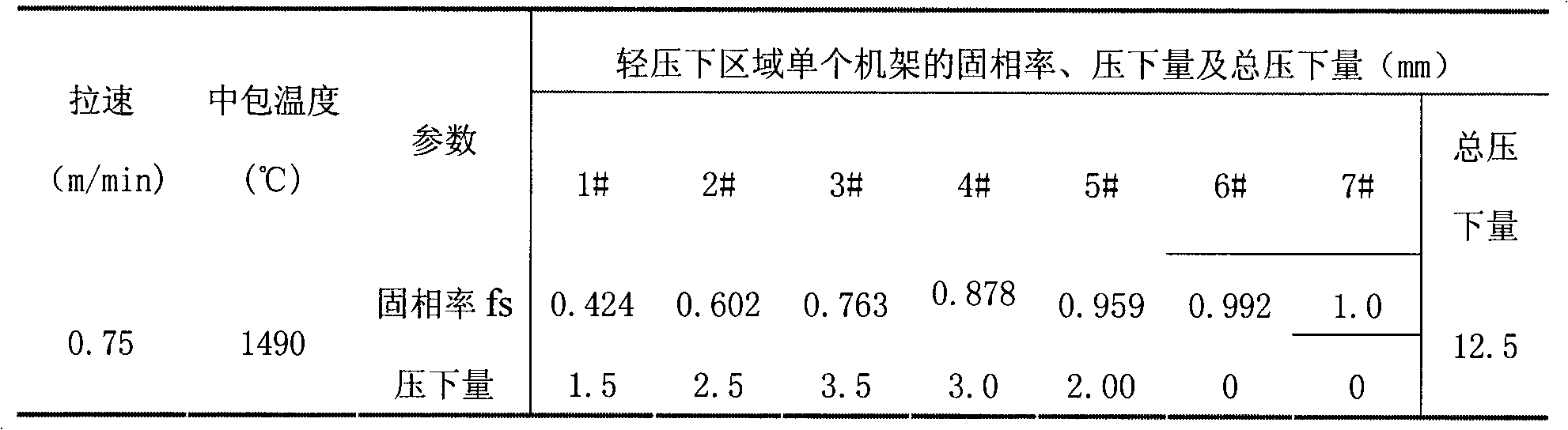

[0034] The main process parameters of pouring heat continuous casting are shown in the table below:

[0035]

[0036] The process of the present invention reduces and eliminates defects such as slab center segregation, center looseness, and center shrinkage cavity through continuous casting slab dynamic light reduction, and the carbon segregation index of the slab center is reduced from 1.25 to 1.38 to 0.95 to 1.08, with an average of 1.03; The proportion of billet center porosity ≤ 1.0 is increased from 28% to 100%, and the center shrinkage ≤ 0.5 is increased from 45% to 100%, and the bearing steel rolled by continuous casting billet meets the requi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com