Automatic lifting mechanism

A technology of automatic lifting and driving device, applied in the direction of lifting device, electrical components, electric solid devices, etc., can solve the problems of the effective working stroke limited by oil volume, loud noise, fine dust particles, short service life, etc., and achieve a simple structure. Compact, high cleanliness, improved cleanliness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

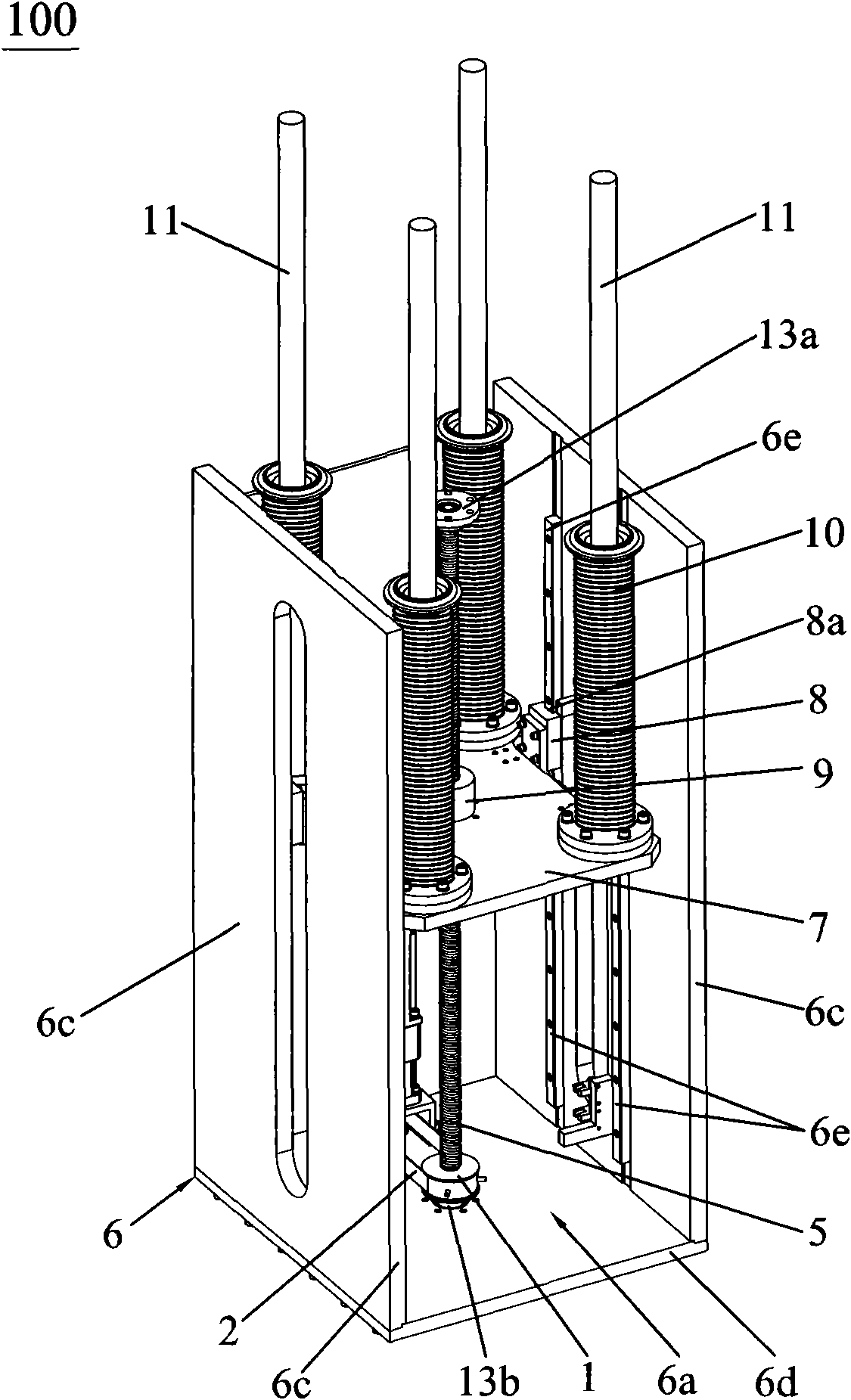

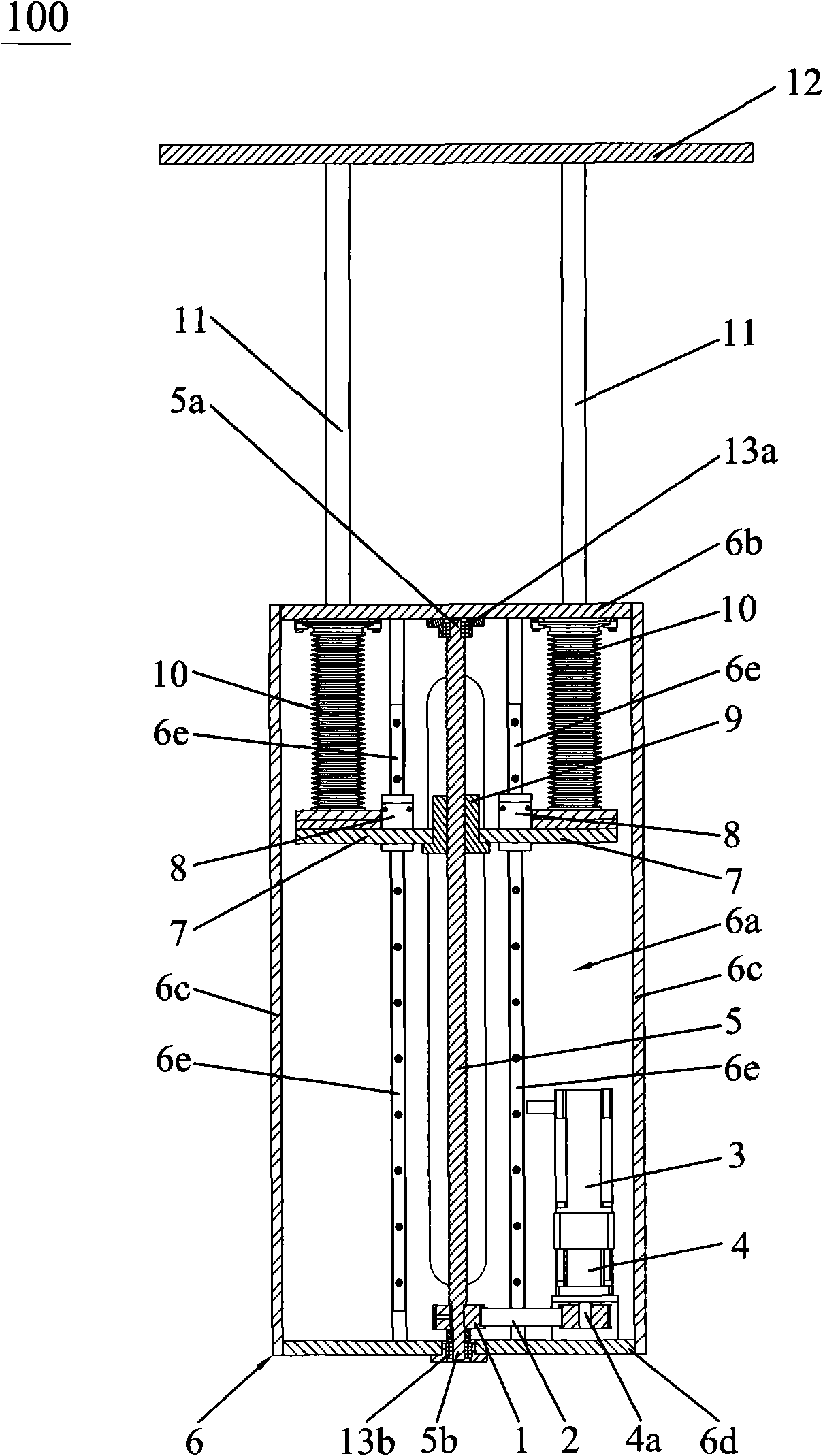

[0015] Such as figure 1 and figure 2 As shown, the automatic lifting mechanism 100 of the present invention includes a support box 6, a workbench 12, a pillar 11, a transmission device, a driving device and a control device (not shown in the figure), the support box 6 is a hollow structure, and the hollow structure forms Placement chamber 6a, one end of the pillar 11 passes through the top wall 6b of the support box 6 and is connected with the workbench 12, the other end of the pillar 11 is connected with the transmission device, and the drive device is connected with the The transmission device is accommodated in the placement cavity 6a, the drive device is connected to the transmission device, the control device is electrically connected to the drive device, the control device controls the drive device, and the drive device Drive the transmission device, the transmission device drives the pillar 11 to do linear reciprocating motion, wherein the transmission device includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com