Coke oven gas fan with high transmission shaft sealability

A technology of sealing performance and coke oven gas is applied in coke ovens, coke oven heating, dry distillation gas discharge devices, etc. Prevent leakage, maintain long-term efficient and stable operation, and maintain clean and hygienic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

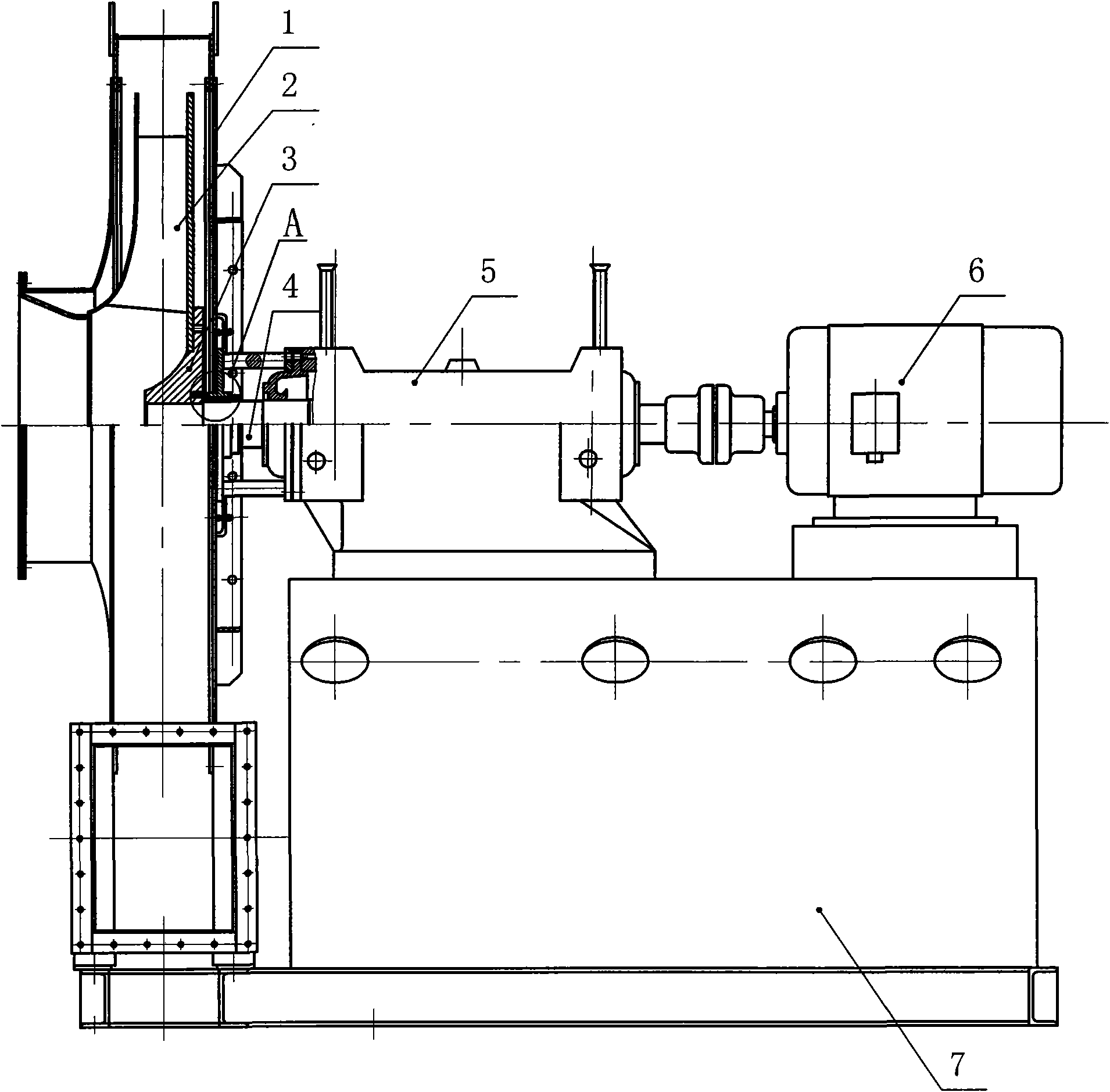

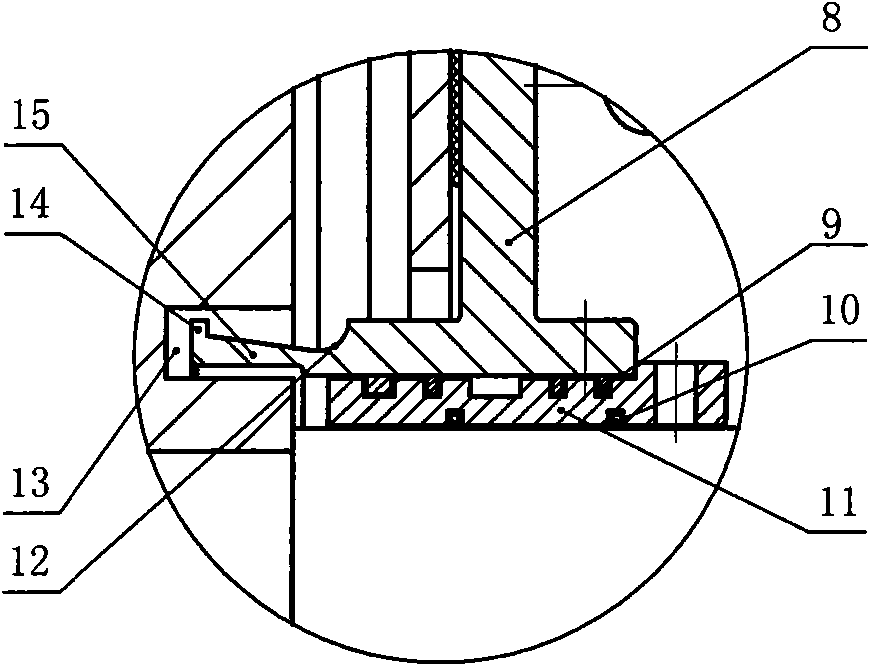

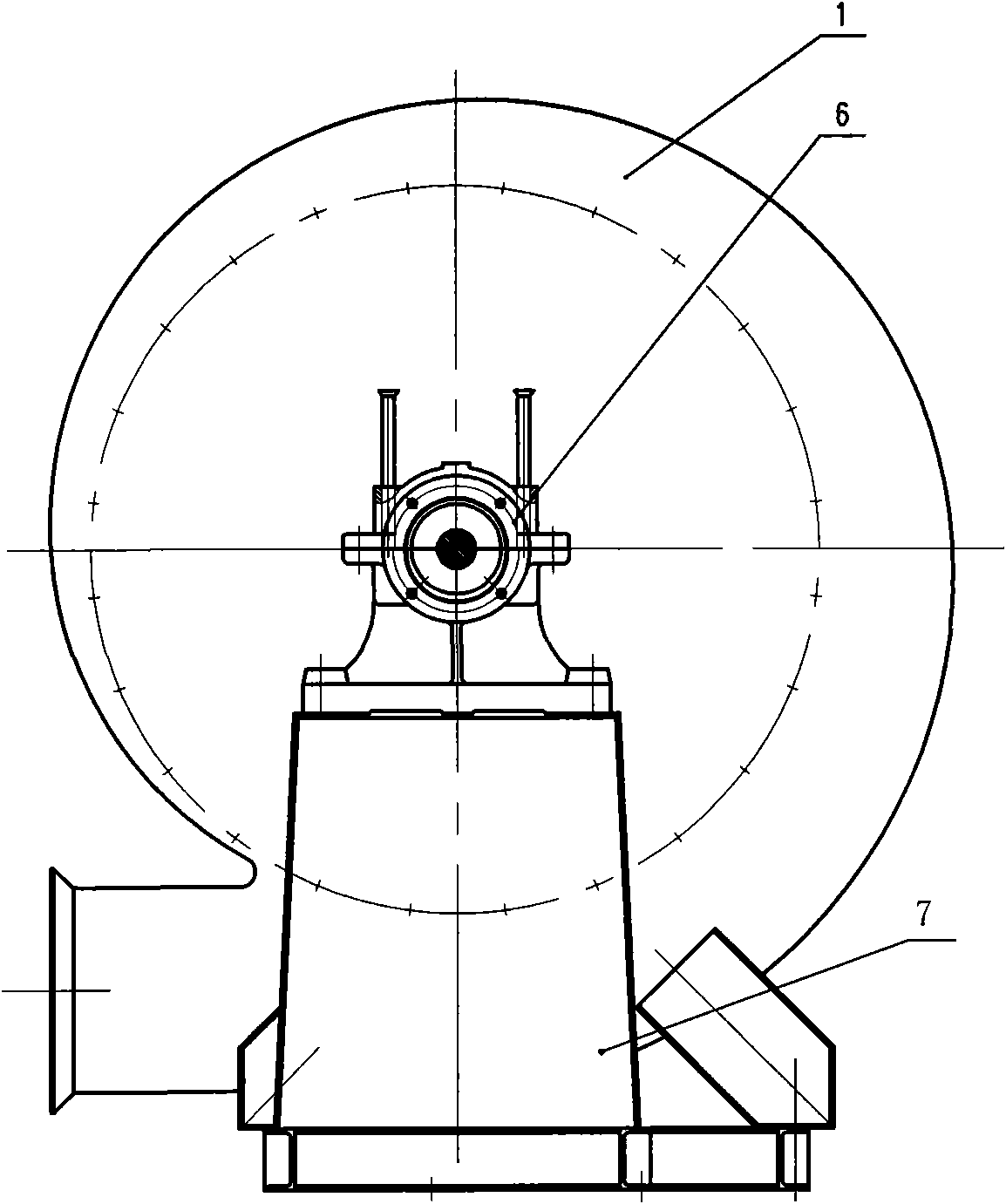

[0018] A coke oven gas blower with high transmission shaft sealing performance is composed of a motor unit 6, a transmission unit 5, an impeller 2, and a casing 1, and the motor unit and the transmission group are installed on the outer base 7 of the side plate of the casing. The power transmission shaft 4 of the transmission group output end is worn on the casing side plate and stretches into the casing inside, and the impeller of the wheel disc 3 is fixedly installed at the end of the transmission shaft stretching into the casing. The outer sealing sleeve 8 is coaxially set on the part of the drive shaft that is mounted on the side plate of the casing, and the outer sealing sleeve is fixedly installed with the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com