Production method of super-good light worsted woolen fabric

A production method and wool fabric technology are applied in the production field of super-bright worsted wool fabrics, which can solve the problems of inability to add softeners, low production efficiency, slow speed, etc., and achieve bright fabrics, high production efficiency, and bright gloss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

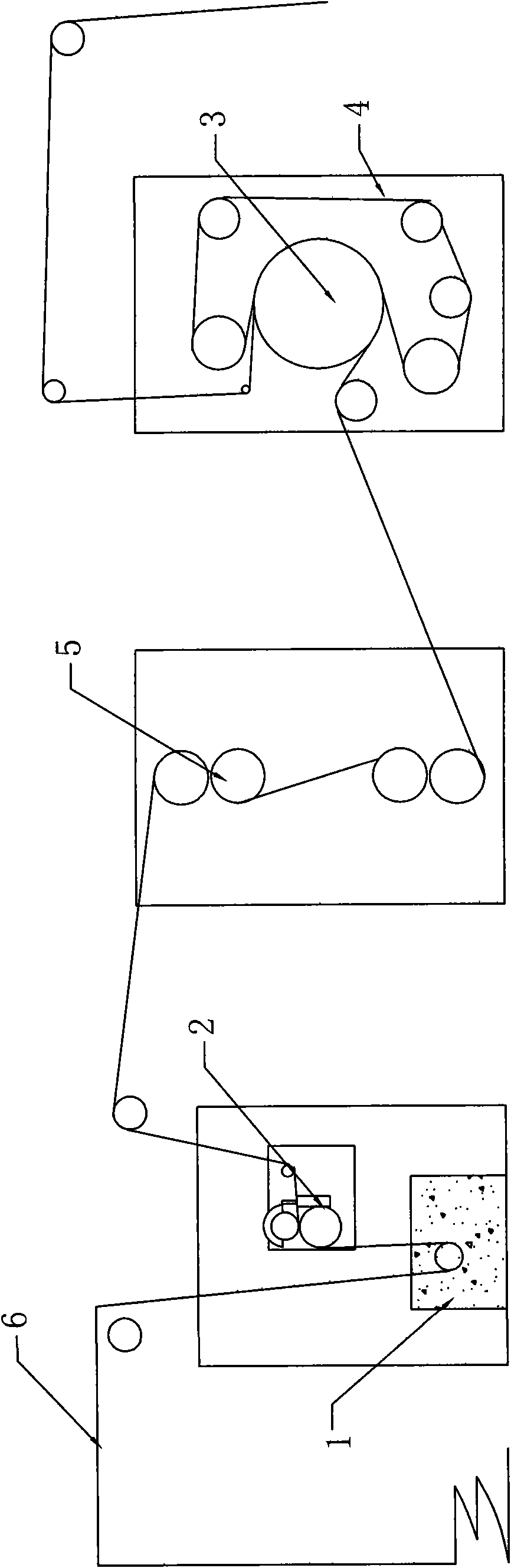

Image

Examples

example 1

[0009] Example 1. Singe the gray fabric of wool, polyester and tweed with fiber weight percentage content of 70% wool / polyester 30%, yarn count 90 / 2*50 / 1 and fabric weight 230 g / m → boil → wash →Boiling→drying→intermediate inspection→cloth repairing→shearing→rolling liquid→pressing→drying→baking→dry finishing→finished product; the temperature for boiling is 85°C and the time is 25 minutes; the temperature for washing is 50°C, the time is 40 minutes; the drying temperature is 95°C; the baking temperature is 180°C, and the time is 45 seconds; it is characterized in that the fabric gray cloth is softened after shearing. After soaking and rolling, add SPM softener from Shanghai Corning Company in the bath, the concentration of the softener in the bath is 50g / l, the pressure of the roller is 6bar, and the speed is 30m / min; Calendering treatment, which is to carry out high-temperature and high-pressure treatment on the gray fabric of the fabric through 2 sets of high-temperature met...

example 2

[0010] Example 2. The pure wool tweed gray cloth whose fiber weight percentage content is wool 97% / polyester 3%, yarn count is 80 / 2*45 / 1 and fabric weight is 225 g / m is singed → boiled → washed Fabric→cooking→drying→intermediate inspection→cloth trimming→shearing→rolling liquid→pressing→drying→baking→dry finishing→finished product; the temperature of boiling is 85℃, and the time is 25 minutes; the temperature of washing The temperature is 50°C, and the time is 40 minutes; the drying temperature is 95°C; the baking temperature is 180°C, and the time is 45 seconds; it is characterized in that the fabric gray cloth is softened after shearing, and the process: padding method, One dipping and one rolling, add SPM softener from Shanghai Corning Company in the bath, the concentration of the softener in the bath is 50g / l, the pressure of the roller is 6bar, and the speed is 30m / min; High-temperature calendering treatment, which is to process high-temperature and high-pressure treatmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com