High-power LED light fitting based on MEMS micro-cooling device radiation

A technology of LED lamps and cooling devices, which is applied in the direction of cooling/heating devices of lighting devices, lighting devices, lighting and heating equipment, etc., which can solve the problems of difficulty in guaranteeing service life, affecting the use effect, and unsatisfactory heat dissipation effect of high-power LED lamps, etc. problem, to achieve the effect of compact structure, improved heat dissipation efficiency, and good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

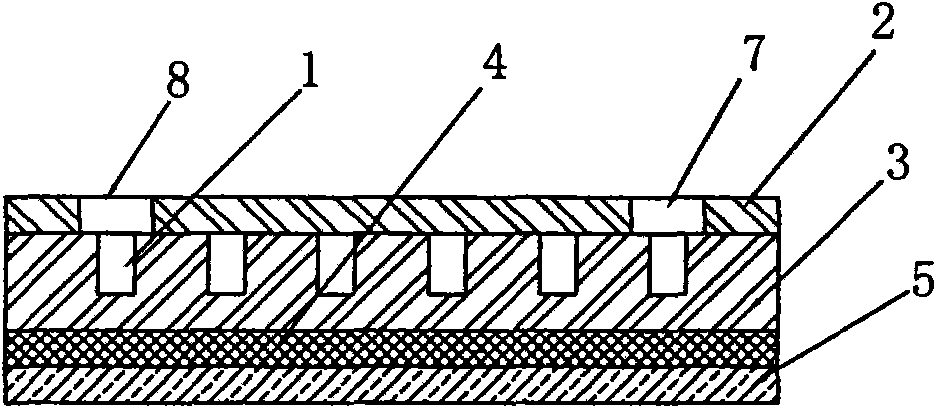

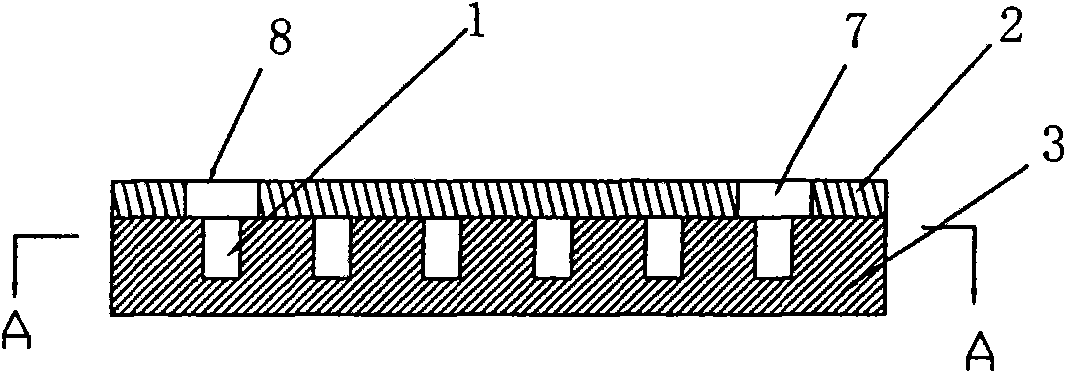

[0024] Such as figure 1 , 3 , 4 shown.

[0025] A high-power LED lamp based on a MEMS micro-cooling device for heat dissipation, including a PCB board 5 for installing LED chips, and the side of the PCB board 5 that is not equipped with LED chips is connected to the bottom phase of the diamond matrix 3 phases. The diamond substrate 3 is provided with a continuous S-shaped microfluid cooling channel 1 (such as Figure 4 ), the microfluid cooling channel 1 is equipped with a sealing plate 2, and the sealing plate 2 is provided with a microfluid inlet hole 7 and a microfluid outlet hole 8 communicating with the microfluid cooling channel 1, and the microfluid is installed in the microfluid cooling channel 1. The flow takes away the heat emitted by the LED chip during use and conducted to the diamond substrate 3 . During specific implementation, the diamond matrix 3 can be bonded and connected with the PCB board 5 on which the LED chip is installed through the thermally conduct...

Embodiment 2

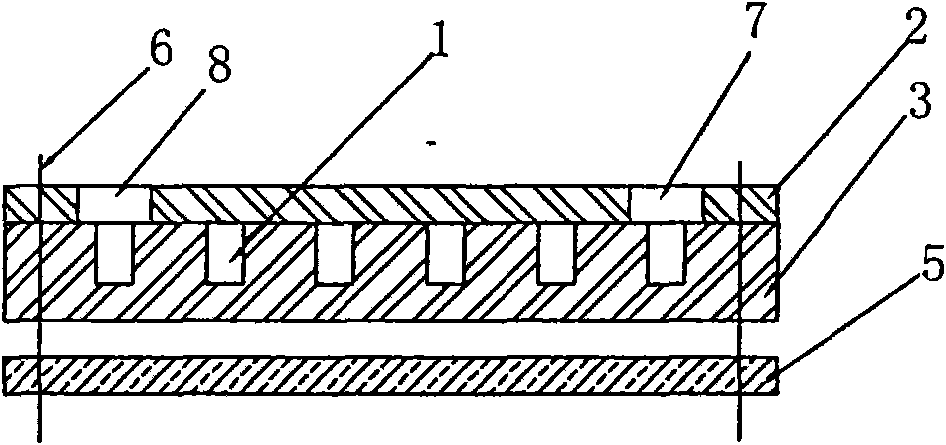

[0027] Such as figure 2 , 3 , 4 shown.

[0028] A high-power LED lamp based on a MEMS micro-cooling device for heat dissipation, including a PCB board 5 for installing LED chips, and the side of the PCB board 5 that is not equipped with LED chips is connected to the bottom phase of the diamond matrix 3 phases. The diamond substrate 3 is provided with a continuous S-shaped microfluid cooling channel 1 (such as Figure 4 ), the microfluid cooling channel 1 is equipped with a sealing plate 2, and the sealing plate 2 is provided with a microfluid inlet hole 7 and a microfluid outlet hole 8 communicating with the microfluid cooling channel 1, and the microfluid is installed in the microfluid cooling channel 1. The flow takes away the heat emitted by the LED chip during use and conducted to the diamond substrate 3 . During specific implementation, the diamond matrix 3 can be bonded to the PCB board 5 for installing the LED chip by connecting bolts 6, such as figure 2 shown. M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com