Thinning-free accurate seeder

A seeder and thinning-free technology, applied in fertilizers and sowing equipment, planting methods, fertilization devices, etc., can solve problems such as affecting the germination rate of seeds, and achieve the goal of maintaining soil structure and moisture, improving adaptability, and suppressing and increasing moisture. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

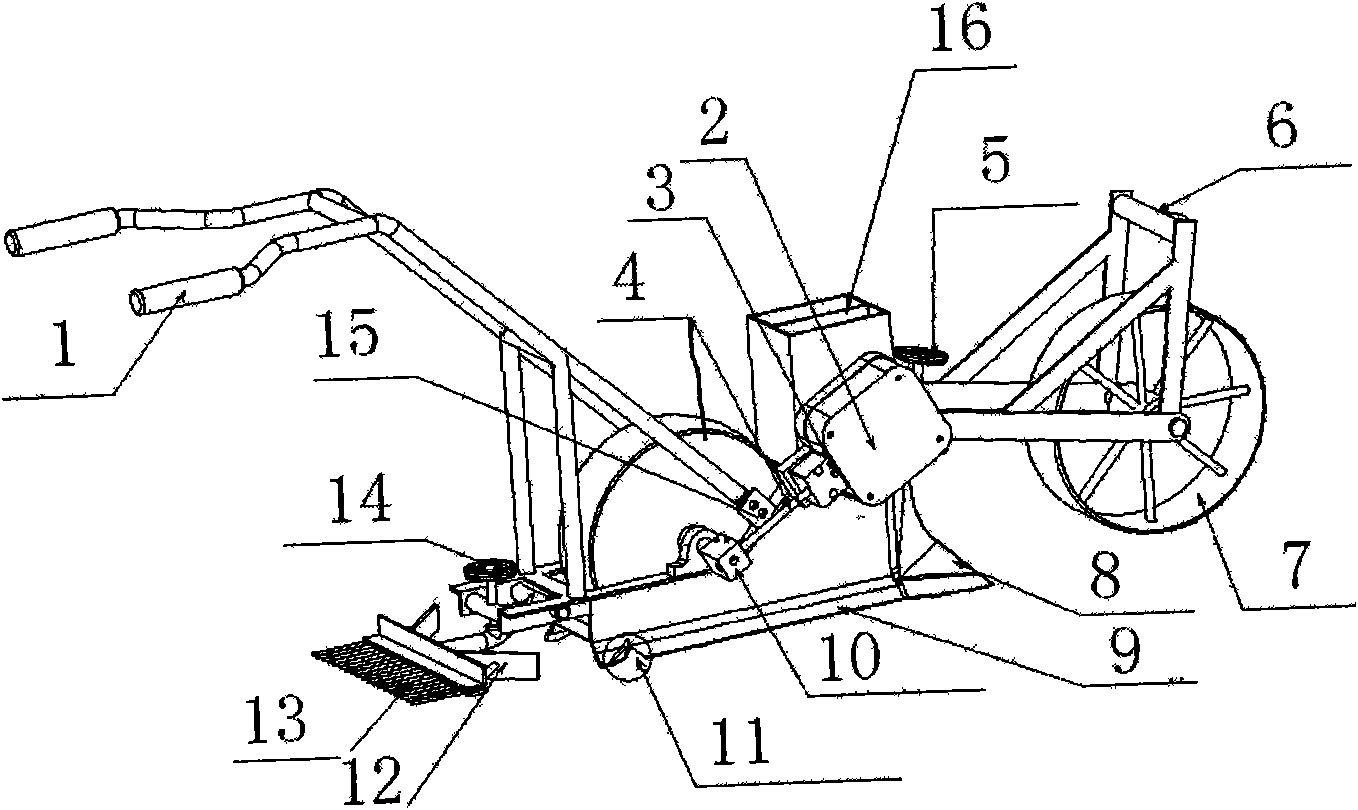

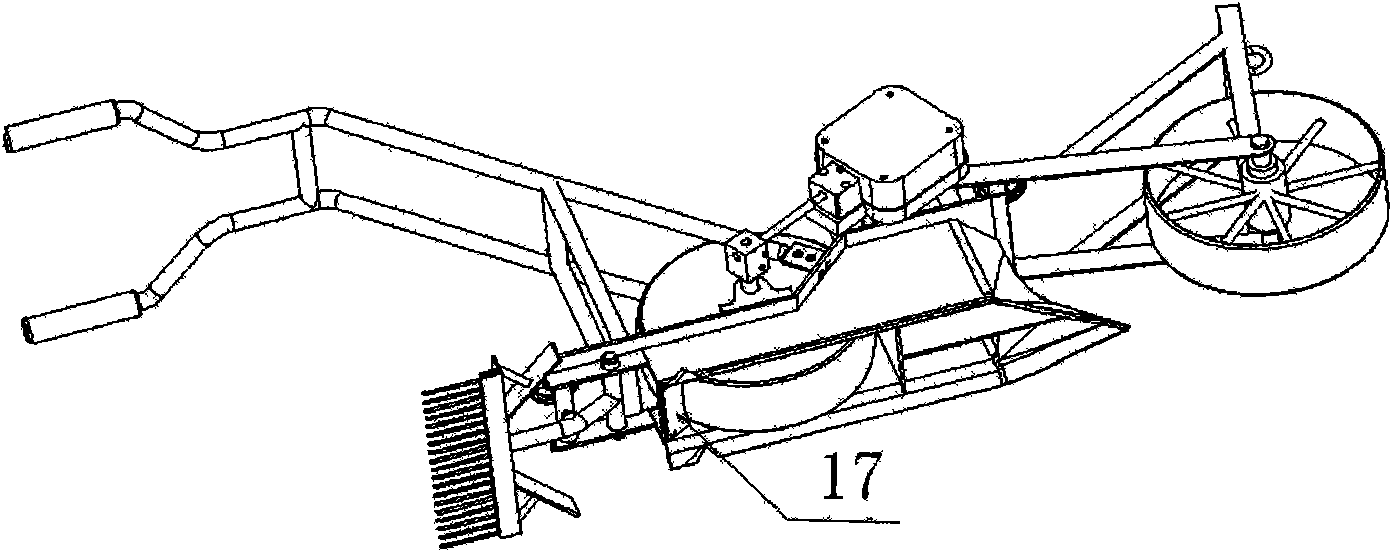

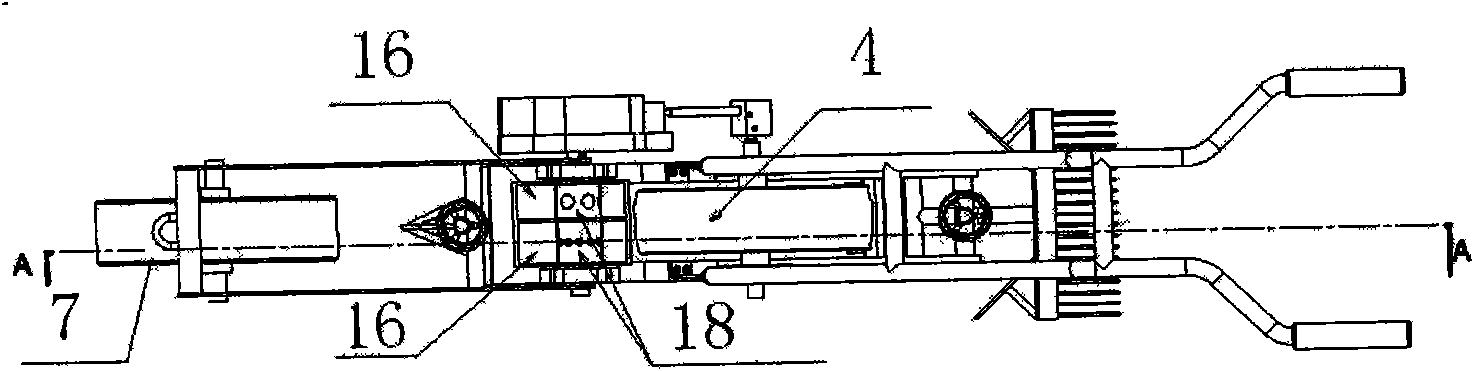

[0019] Such as figure 1 , 2 As shown, a kind of thinning-free precision planter includes a frame 15, a depth-limiting wheel 7 is provided in front of the frame 15, a seed pressing wheel 4 is provided behind the frame 15, and a material box 16 is provided in the middle, behind the seed pressing wheel 4 A soil covering device is provided, and the material box 16 is divided into a seed box and a fertilizer box, and a seed row and fertilizer device 18 is arranged at the bottom of the material box 16, and the seed row and fertilizer device 18 is linked by the shaft of the transmission 2 and the pressing wheel 4, Seed and fertilizer discharger 18 is connected with seed box and fertilizer box respectively, and ditching soil expander is provided at the bottom of frame 15. The front side of ditching soil expander is pointed shovel 8 obliquely downward, and the two sides are soil retaining plates. 9. The rear portion of the retaining plate 9 is also provided with a forced entrance 11 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com