Method for trapping burner smoke of stamp-charged coke oven

A technology for tamping coke ovens and burner smoke, applied to coke ovens, chemical instruments and methods, cleaning methods and appliances, etc., can solve the problems of heavy weight of the whole set of equipment, tight layout space, unfavorable installation of brackets, etc., and achieve pipe material saving , compact layout, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

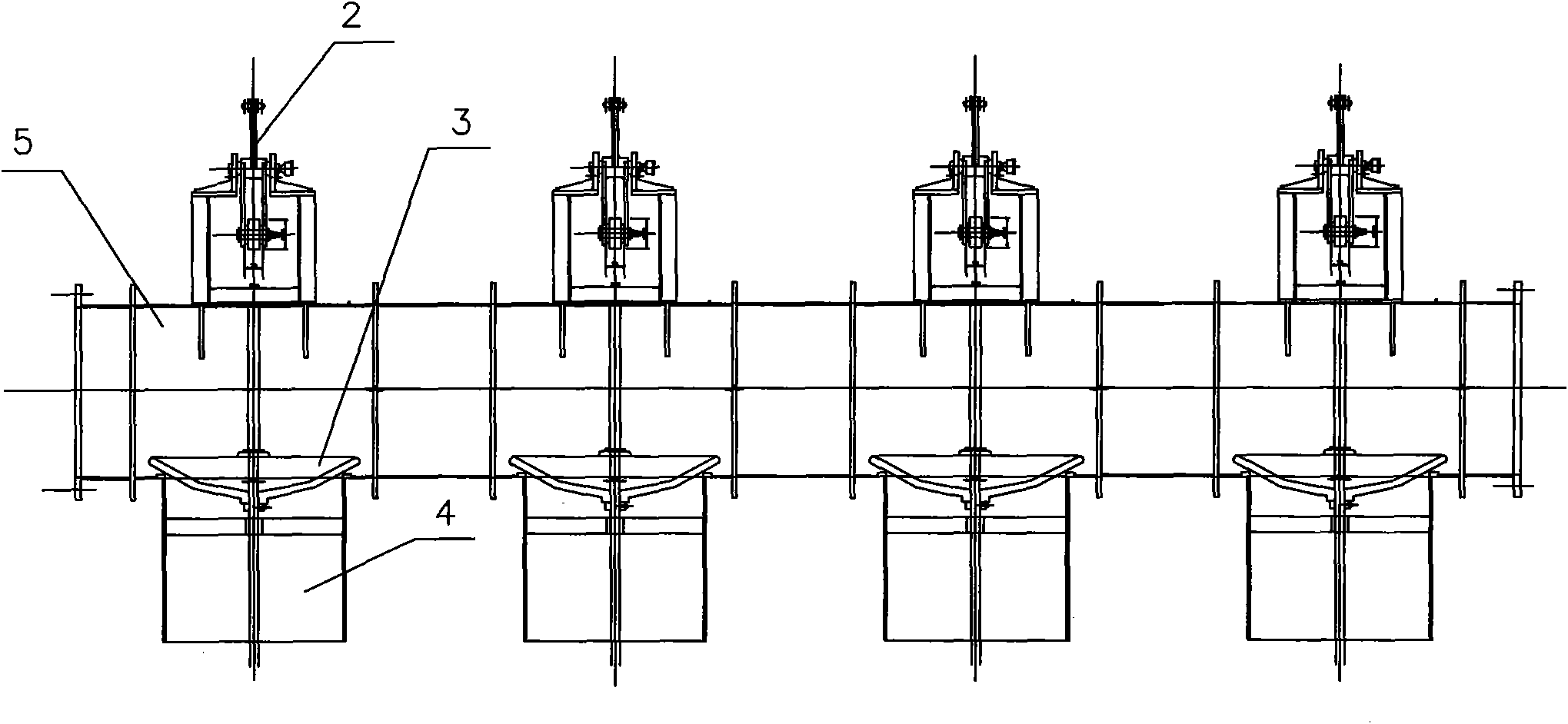

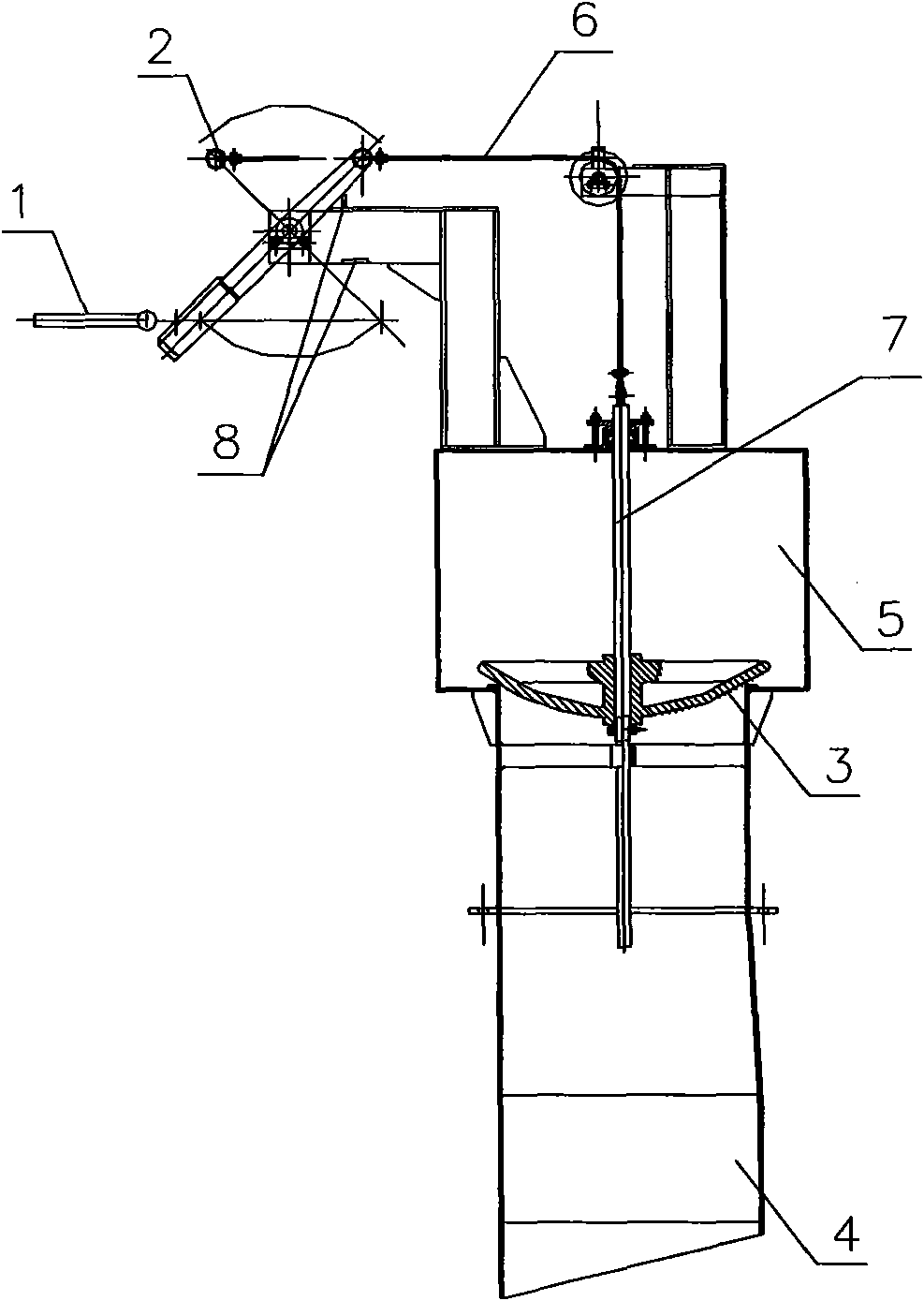

[0017] See figure 1 , figure 2 , a tamping coke oven burner smoke capture method, which transmits the burst burner smoke generated on the side of the machine to the fixed flue gas dust removal equipment through the valve group and the gas collection pipeline. The lift of the poppet valve plate in the group is used to capture the smoke from the burner. The trapping device includes a valve group and a gas-collecting pipe. The valve group is used in conjunction with the smoke guide truck installed on the furnace roof. The number of valve groups corresponds to the number of coke oven doors. The gas-collecting pipe 5 is located directly above the collection hood 4. , each valve body of the valve group is arranged at the connection between the gas collection pipe 5 and the collection cover 4 . Compared with the separate arrangement of the gas-collecting pipeline and the trapping poppet, this arrangement reduces the occupied space and makes the whole set of trapping valve group li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com