Diamond reinforced metal-base composite material for electronic packaging and preparation method thereof

A technology for diamond reinforced and composite materials, which is applied to the field of diamond reinforced metal matrix composite materials for electronic packaging and its preparation, can solve the problems of high preparation cost, high cost, poor mechanical properties of materials, etc., and achieves reduction of thermal expansion coefficient and simplification of preparation process. , The effect of simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

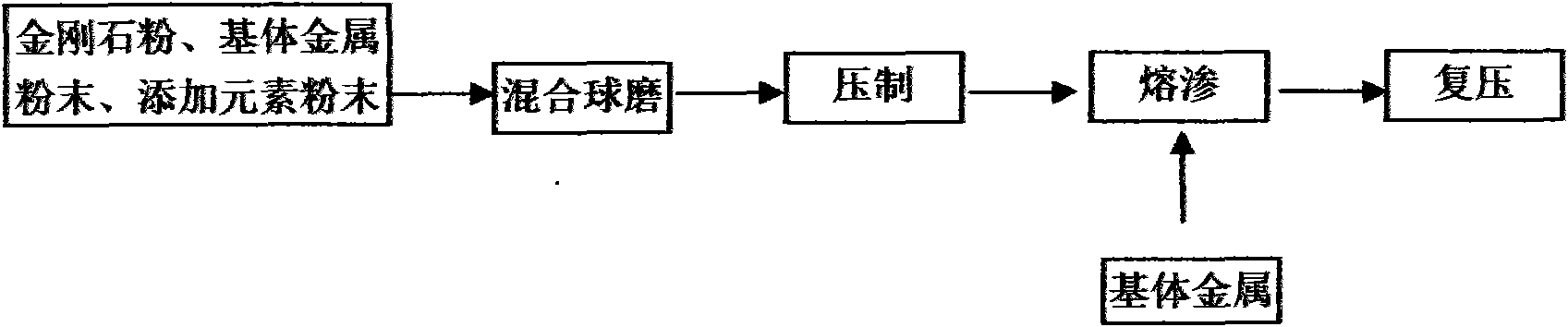

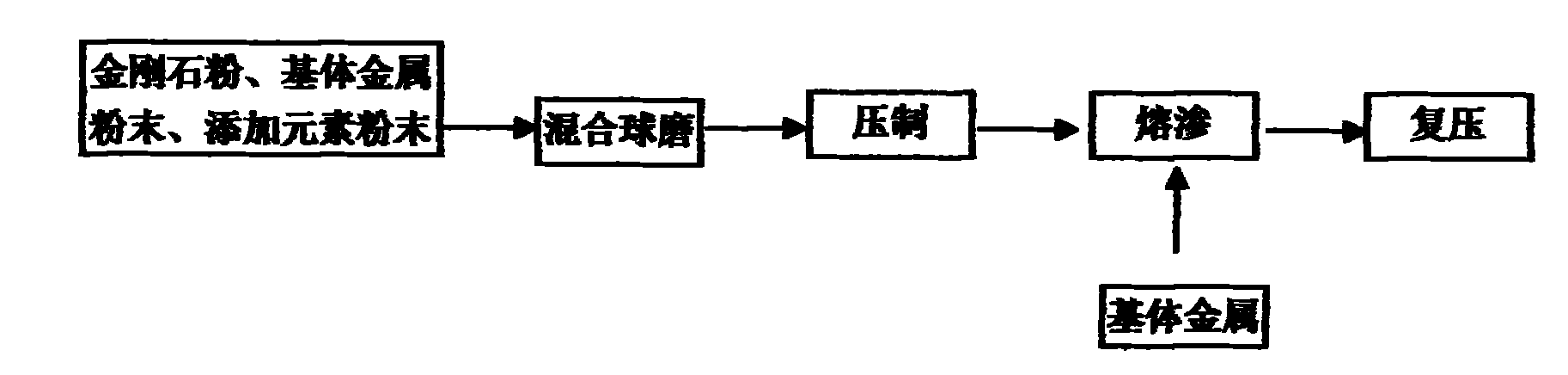

Method used

Image

Examples

Embodiment 1

[0032] Take the preparation of Ag-30% diamond with a thickness of 0.5mm as an example

[0033] First, 30% Ag powder, 30% diamond powder (150 μm in particle size) and 0.1% Cr powder are mixed and ball-milled, the ball-to-material ratio is 1:1, and the ball-milling time is 20 h;

[0034] Then the ball-milled powder is pressed into a green body under a pressure of 50 MPa;

[0035] The compact is infiltrated together with 39% Ag metal in an infiltration furnace, the infiltration temperature is 1250°C, the infiltration time is 5min / mm×0.5mm=2.5 minutes, and the atmosphere is a hydrogen atmosphere;

[0036]After the infiltration is completed, the sample is repressed on a four-column press at 500MPa for 1 minute to obtain a 30% diamond-reinforced silver-based composite material with a thermal conductivity of 550W / m.K and a thermal expansion coefficient of 8.5×10 -6 / K, the bending strength is 300MPa.

Embodiment 2

[0038] Take the preparation of Ag-90% diamond with a thickness of 200mm as an example

[0039] First, 5% Ag powder, 90% diamond powder (with a particle size of 1 μm) and 5% B powder are mixed and ball-milled, the ball-to-material ratio is 20:1, and the ball-milling time is 1 h;

[0040] Then the ball-milled powder is pressed into a green body under a pressure of 150MPa;

[0041] The compact is infiltrated together with 4% Ag metal in an infiltration furnace, the infiltration temperature is 1000°C, the infiltration time=2min / mm×200mm=400 minutes, and the atmosphere is a hydrogen atmosphere;

[0042] After the infiltration is completed, the sample is repressed on a four-column press at 100MPa for 10 seconds to obtain a 90% diamond-reinforced silver-based composite material with a thermal conductivity of 700W / m.k and a thermal expansion coefficient of 4.5×10 -6 / K, the bending strength is 450MPa.

Embodiment 3

[0044] Taking the preparation of Cu-30% diamond with a thickness of 0.5mm as an example

[0045] Firstly, 30% Cu powder, 30% diamond powder (with a particle size of 150 μm) and 0.1% Zr powder are mixed and ball-milled, the ball-to-material ratio is 1:1, and the ball-milling time is 20 h;

[0046] Then the ball-milled powder is pressed into a green body under a pressure of 50 MPa;

[0047] The compact is infiltrated together with 39% Cu metal in an infiltration furnace, the infiltration temperature is 1350°C, the infiltration time=5min / mm×0.5mm=2.5 minutes, and the atmosphere is a hydrogen atmosphere;

[0048] After the infiltration is completed, the sample is repressed on a four-column press at 500MPa for 1 minute to obtain a 30% diamond-reinforced copper-based composite material. The thermal conductivity of the material is 450W / m.K and the thermal expansion coefficient is 9.0×10 -6 / K, the bending strength is 350MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com