Optical detection method of verticality error of longitudinal axis and latitudinal axis of horizontal type telescope

A telescope and horizontal technology, applied in the direction of using optical devices, measuring devices, instruments, etc., can solve problems such as inappropriate promotion and complicated calculation process, and achieve the effect of reliable measurement method, simple method principle and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in further detail below in conjunction with the example given.

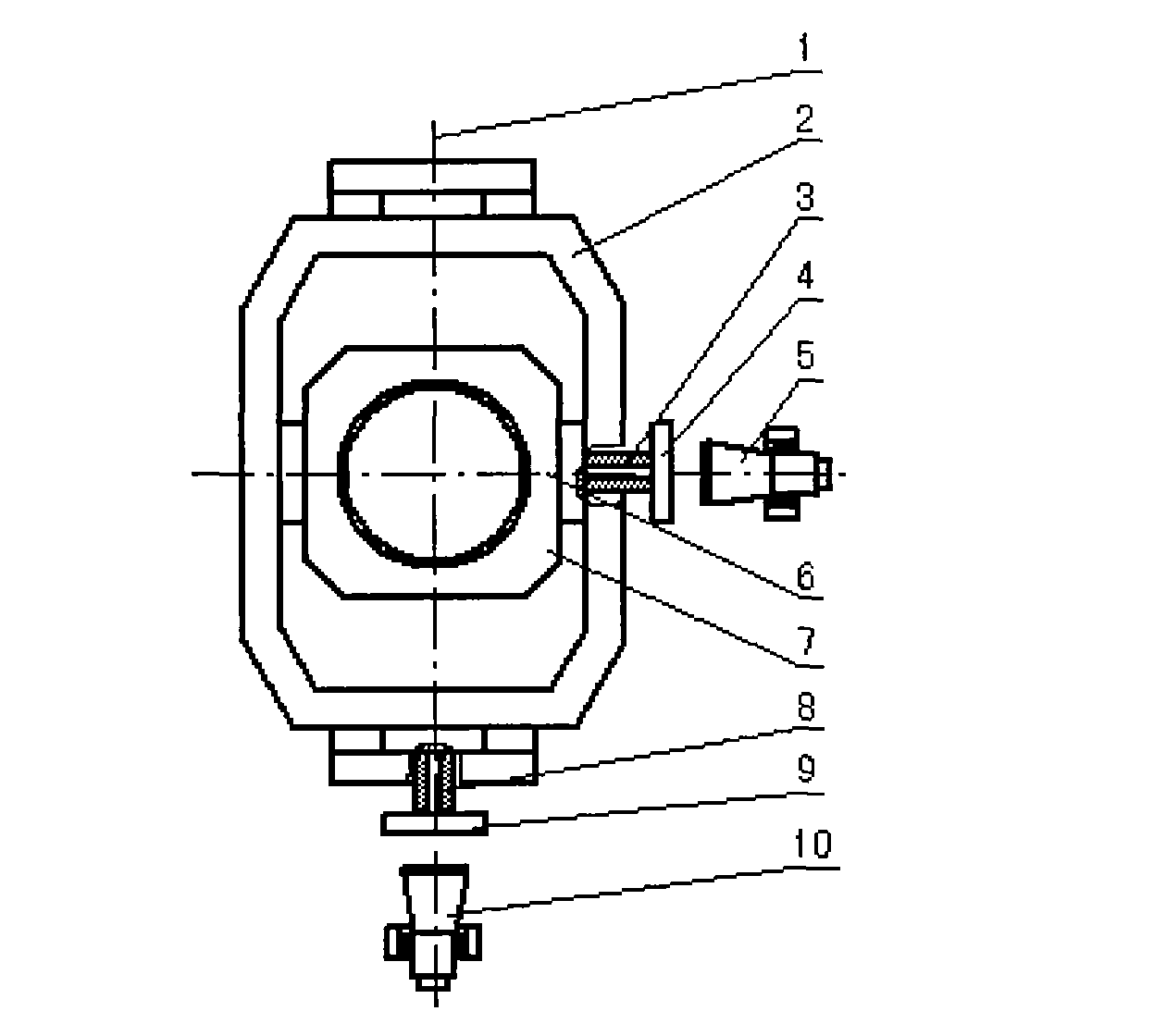

[0018] The present invention detects the method for the perpendicularity error of the longitude and latitude axes of the horizontal telescope, such as image 3 As shown, a plane reflector 4 is installed on the latitude axis 3 axis head of the horizontal telescope to be measured, a theodolite 5 is correspondingly placed outside the plane reflector 4, and the installation angle of the plane reflector 4 and the pendulum of theodolite 5 are adjusted. Place the position so that the optical axis of the theodolite 5 coincides with the axis of rotation 6 of the latitudinal axis; another plane reflector 9 is installed on the warp axis 8 axis head of the horizontal telescope to be measured, and another plane reflector 9 is correspondingly placed outside the plane reflector 9 Theodolite 10, adjust the installation angle of plane reflector 9 and the placement position of theodolite 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com