Method for measuring mixing effect of fluid

A fluid mixing and fluid technology, applied in the field of chemical engineering, can solve the problems of high requirements for stirring medium, complex devices, and few applications, and achieve high practical value, reduce economic losses, and the effect of simple and convenient methods

Inactive Publication Date: 2011-01-05

KUNMING UNIV OF SCI & TECH

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In recent years, with the development of science and technology, laser Doppler velocimeter LDV, computational fluid dynamics CFD simulation technology and electron tomography technology have been widely used, which has promoted the rapid development of fluid mixing technology. There are many methods for mixing effects, mainly including conductivity method, thermocouple method, optical method, decolorization method, etc. Among them, the conductivity method is widely used in the mixing and mixing of low-viscosity fluids, but it has high requirements for the stirring medium. The medium is deionized water; the thermocouple method will cause damage to the flow field; the general optical method is rarely used due to the complexity of the device; therefore highly subjective

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

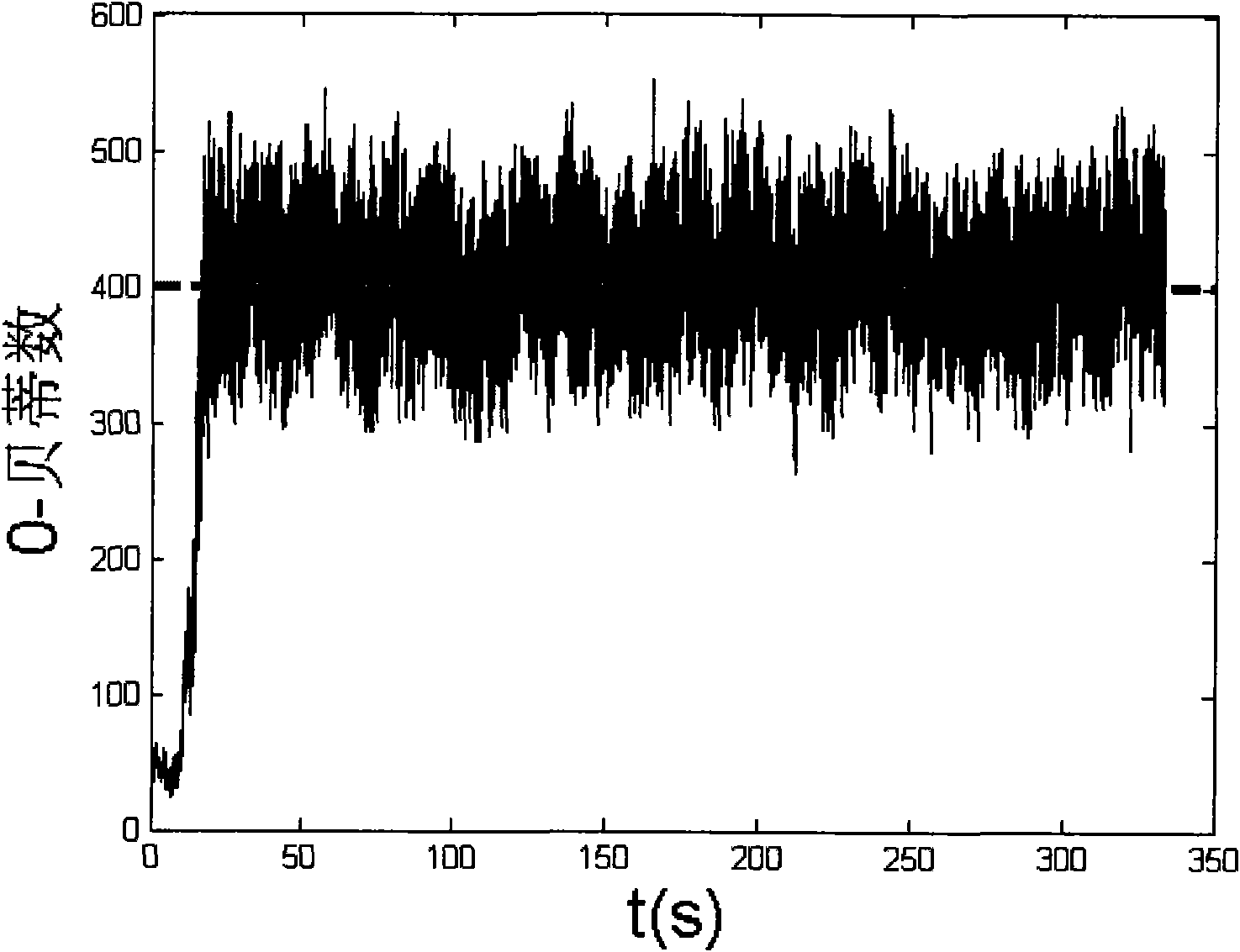

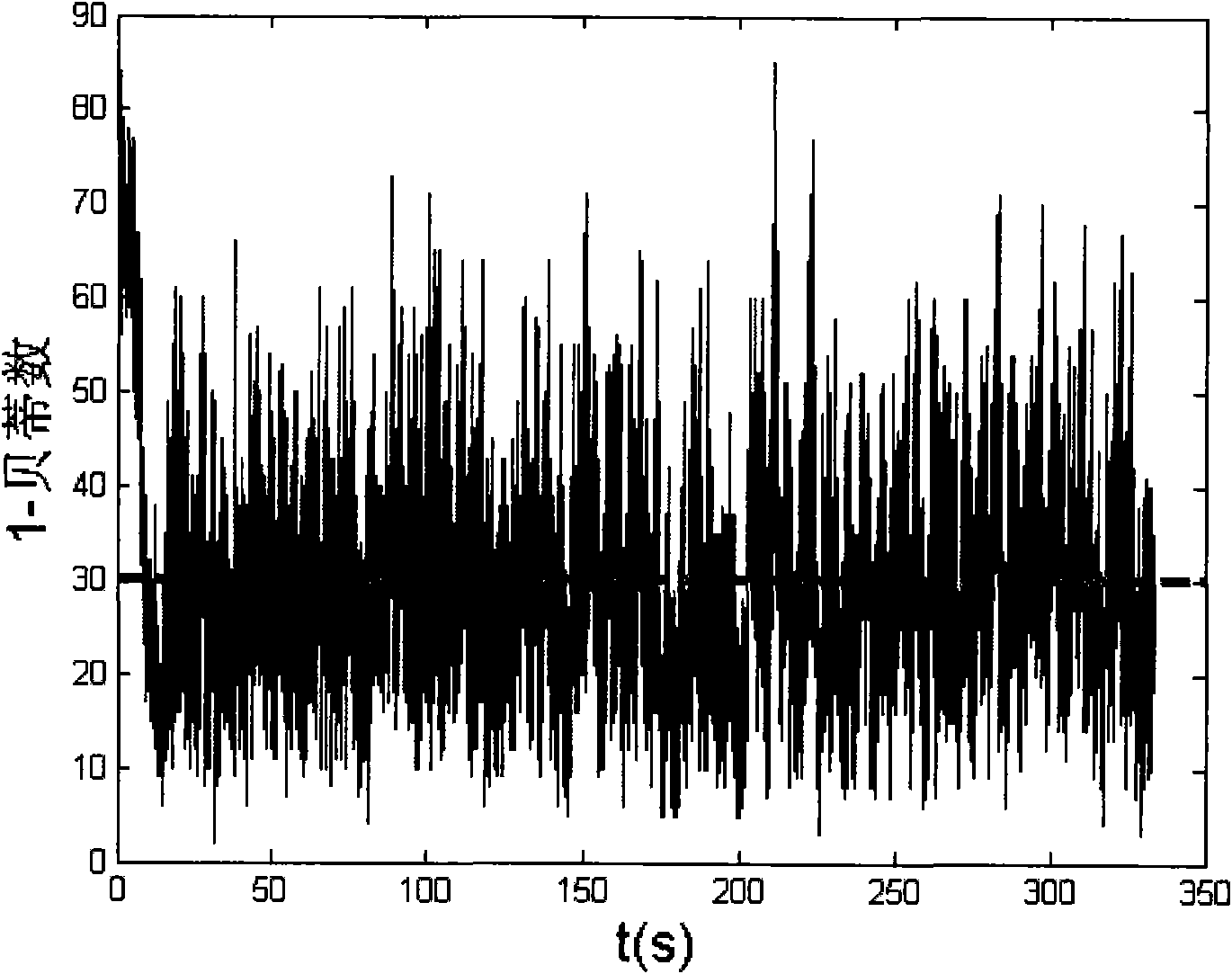

The invention relates to a method for measuring the mixing effect of fluids and is mainly applied to judging the mixing effect of fluids and theoretically guiding the design of experiments in experiments of chemical engineering. The method comprises the following steps: (1) utilizing a particle velometer (transparent or semi-transparent fluid mixing) and the electron tomography (nontransparent fluid mixing) to obtain a fluid mixing real-time pattern; (2) utilizing a written particular program to calculate a 0-dimension Betti number and a 1-dimension Betti number of the obtained real-time pattern; (3) judging the mixing effect through respectively calculating the evolvement of the 0-dimension Betti number and the 1-dimension Betti number of an integral region and the average value of the 0-dimension Betti number and the 1-dimension Betti number of a 4 region or a 16 region. The method is applied to the detection of the mixing effect of all fluids, is simple and convenient and has higher practical value. The invention provides a reliable and practical measuring method for judging the mixing effects and theoretically guiding the design of experiments in experiments of chemical engineering.

Description

A Method of Measuring Fluid Mixing Effect technical field The invention relates to the technical field of chemical engineering, in particular to a method for measuring the mixing effect of fluids which is suitable for detecting the mixing effects of all fluids in the chemical industry. Background technique Mixing is one of the most common critical unit operations in chemical engineering. From the 1960s to the 1980s, fluid mixing technology developed rapidly. The focus of its research is mainly on the use of conventional stirring paddles in heterogeneous systems such as low-viscosity and high-viscosity non-Newtonian homogeneous systems, solid-liquid suspension and gas-liquid dispersion. Experimental research is carried out on macroscopic quantities such as stirring power consumption and mixing time. Although there are a lot of design experience and correlation methods that can be used to analyze and predict mixed systems, it is still not sure to directly scale up the stirr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01N13/00G06F19/00

Inventor 王华徐建新王仕博孙辉

Owner KUNMING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com