Fuel cell sealing method and sealing structure

A fuel cell and sealing structure technology, which is applied to fuel cell parts, structural parts, battery pack parts, etc. , high operator skill requirements, etc., to shorten the production cycle, improve work efficiency and assembly safety, and simplify the assembly process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further described in detail through the following examples in conjunction with the accompanying drawings, but are not limited to the content of this example.

[0026] A fuel cell sealing method, comprising the steps of:

[0027] 1) Carry out mold design according to the shape of membrane electrode, be provided with injection port and exhaust port on described mold;

[0028] 2) Fix and clamp the prepared membrane electrode with the mold, form a closed space connected with the injection port around the membrane electrode, and then inject the sealing material from the injection port until it is filled In the enclosed space, air and excess sealing material are discharged through the exhaust port;

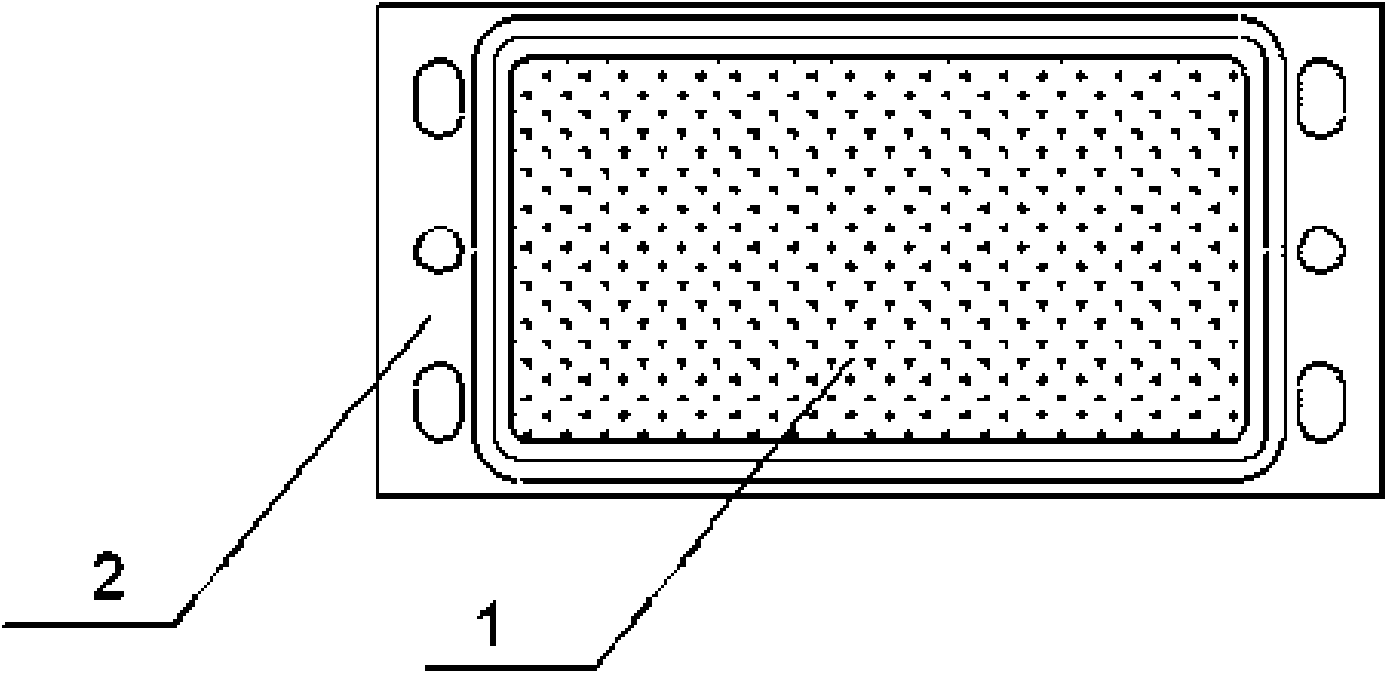

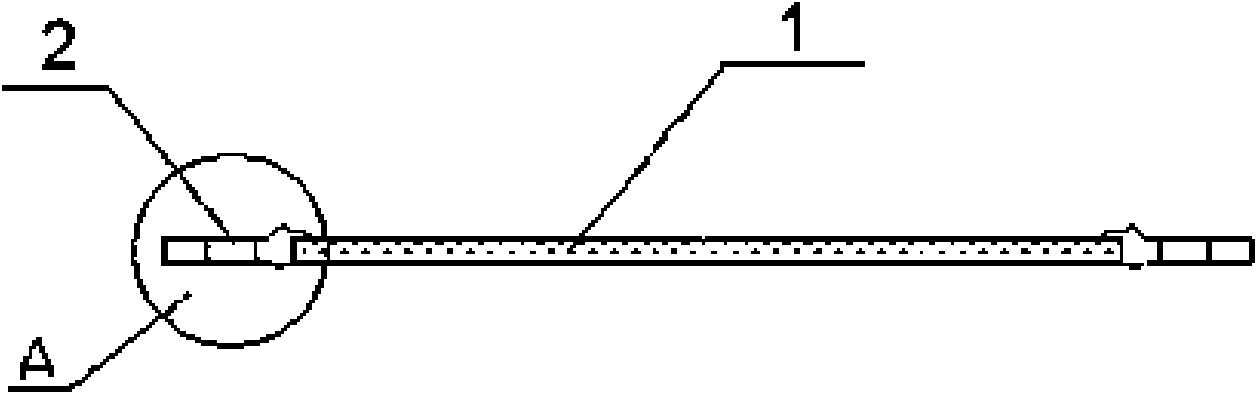

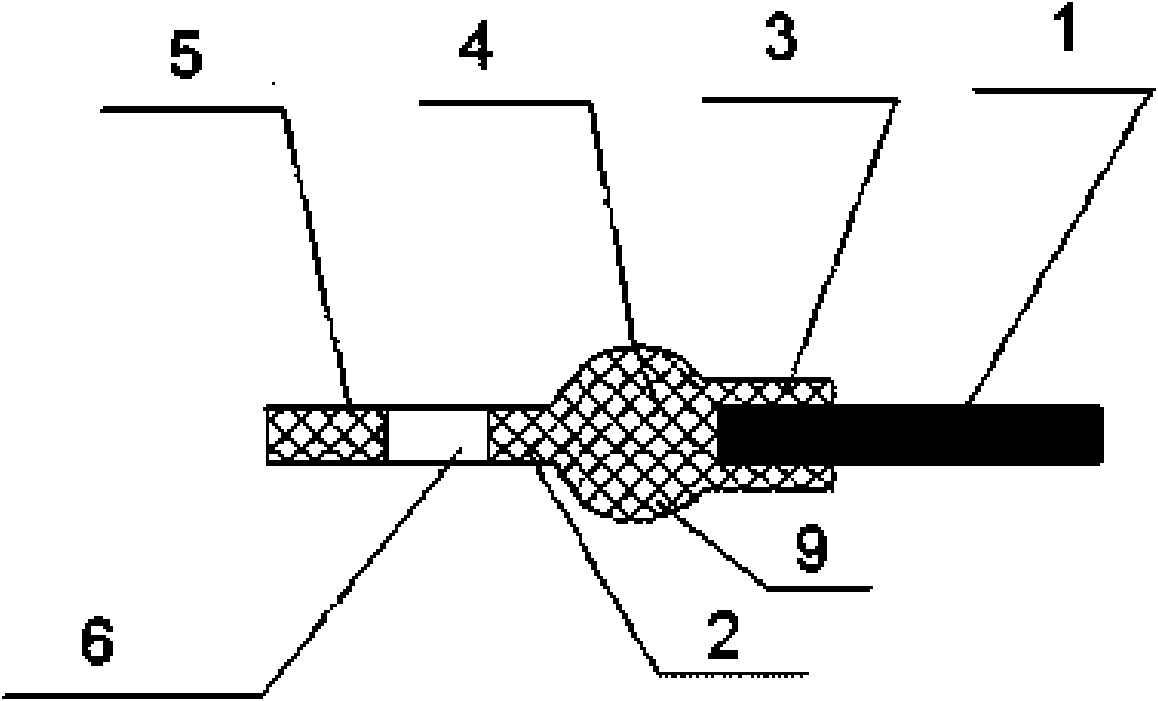

[0029] 3) Under a certain pressure, heat the above-mentioned mold until the sealing material solidifies, remove the mold, and obtain the sealing structure of the fuel cell, such as figure 1 , figure 2 , image 3 shown....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com