Method for manufacturing cold-finished seamless steel pipe for integrally molded drive shaft

A technology of seamless steel pipe and manufacturing method, which is applied in the directions of manufacturing tools, metal processing equipment, shafts, etc., can solve the problems of increasing the wrinkle depth on the inner surface of the pipe, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

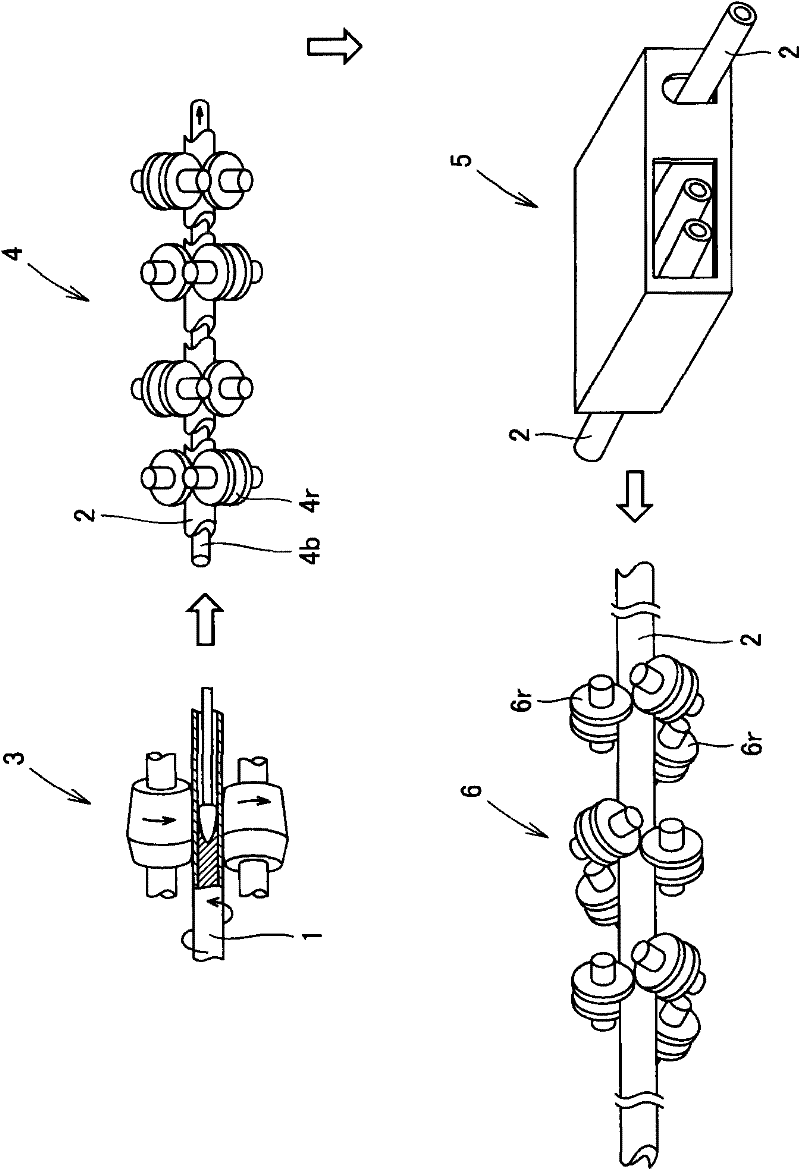

Method used

Image

Examples

Embodiment 1

[0131] In Examples, steel slabs having chemical compositions shown in Table 1 were used. Then, as shown in the column of thermal processing pipe making in Table 2, the piercing and rolling are carried out by ordinary Mannesmann mandrel mill processing, and the pass shape (pass shape) of the 3-roll stretching and shrinking mill is changed. Roll minimum flange contact angle β min ), to manufacture cold-drawn tube blanks with an outer diameter of 45.0 mm and a wall thickness of 7.0 to 7.4 mm.

[0132] [Table 1]

[0133]

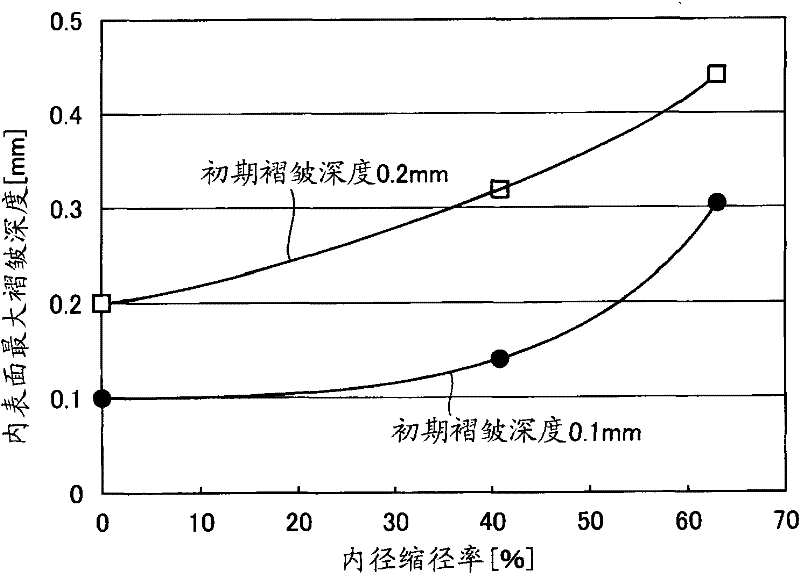

[0134] At this time, the minimum wall thickness in the circumferential direction of the pipe and the depth of the generated inner surface wrinkles were measured. The column of hot-worked tube making in Table 2 also shows the processing conditions (except the roll conditions of the stretching mill) and the measurement results of the minimum wall thickness and inner surface wrinkle depth in the hot-worked tube-making process at this time.

[0135] Cold draw...

Embodiment 2

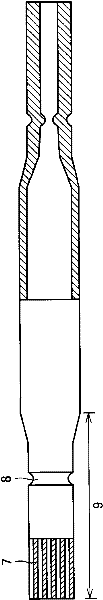

[0150] Using the sample materials A to I subjected to diameter reduction in Example 1, a torsional fatigue test was implemented. As above Figure 4 As shown, for the sample material subjected to diameter reduction processing, the central part of the length of the sample was cut off by 3.5 mm from the outer diameter after cold drawing (to reduce the wall thickness by 1.75 mm), and a parallel part with a length of 150 mm was formed. This part forms a spline, and serves as a sample for simulating a splined portion of an integrally formed drive shaft.

[0151] Figure 8 It is a sectional view showing the splined shape of the sample subjected to the torsional fatigue test used in Example 2. The number of teeth of the spline processing part is slightly different depending on the outer diameter after the above-mentioned outer diameter cutting, but within the range of 25 to 31, the depth of the recess is 0.98mm, and the radius of curvature of the bottom of the recess is 0.4mm. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com