Manufacturing method of individual tongue-side orthodontic retainer

A manufacturing method and retainer technology, which can be applied to brackets and other directions, can solve the problems of failure to hold, easy to loosen, and affect the holding effect, and achieve the effects of wide application range, short manufacturing cycle, and process saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

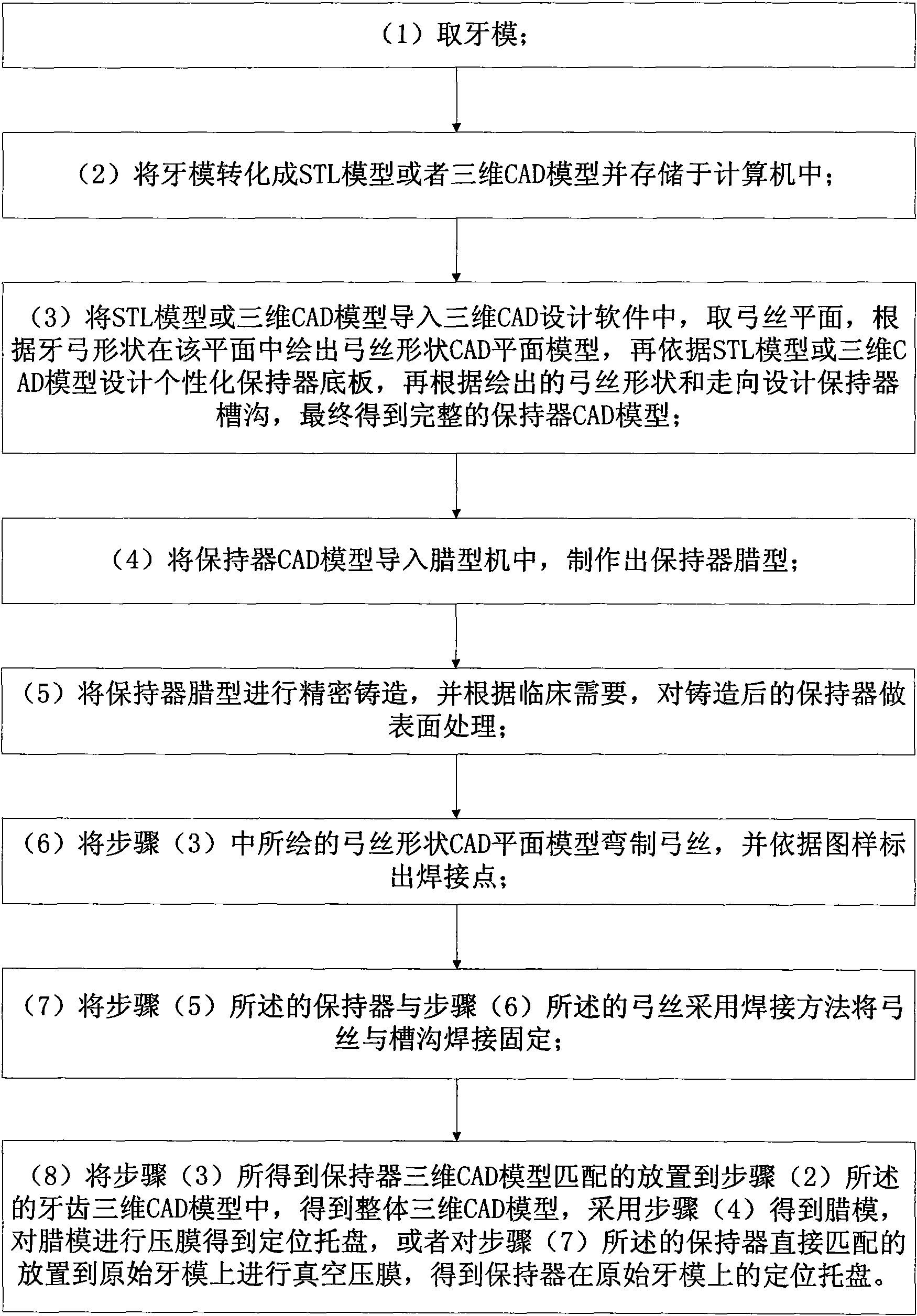

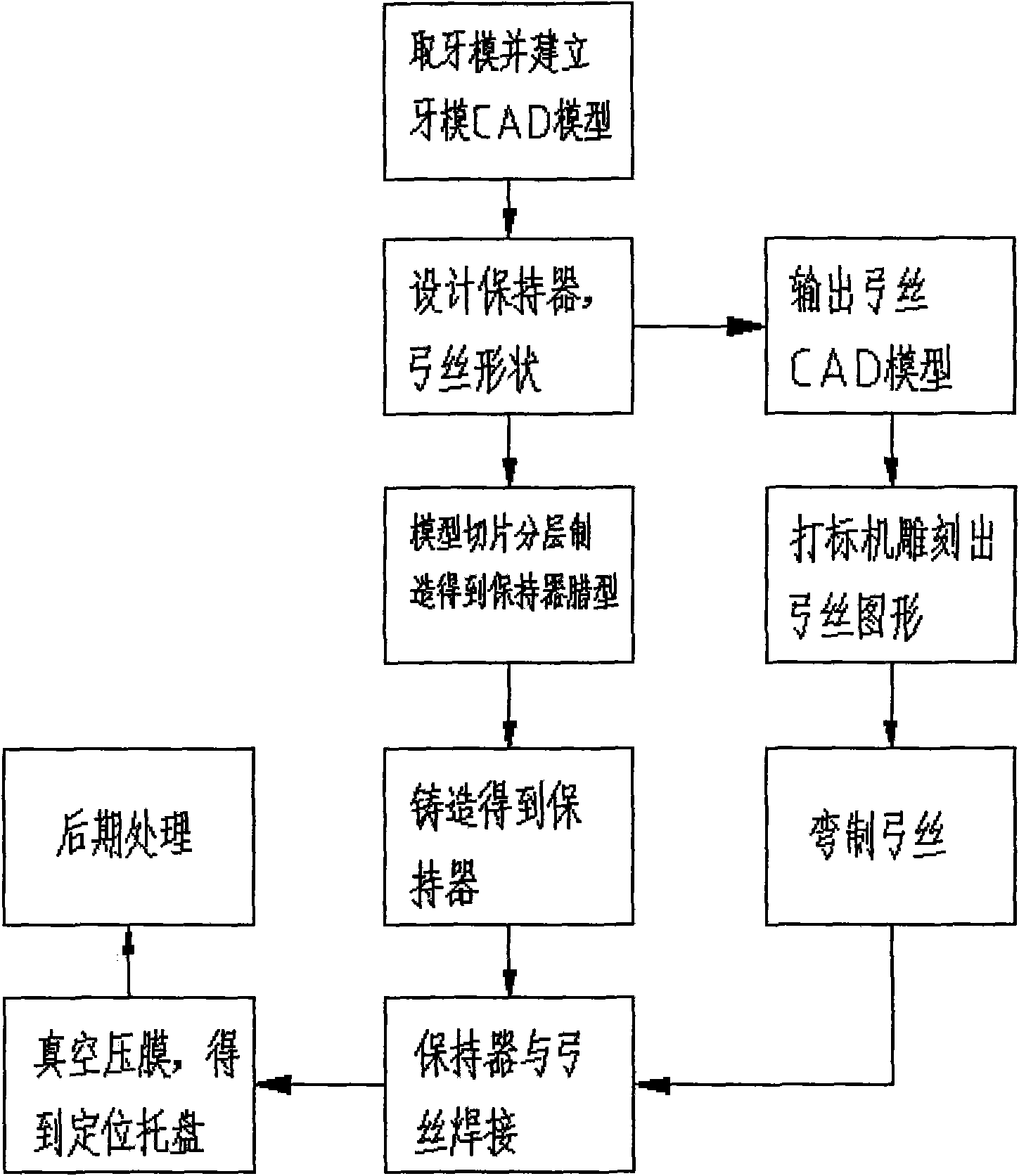

[0034] refer to figure 1 , the manufacturing method of personalized lingual orthodontic retainer, comprises the following steps:

[0035] (1) Take dental model;

[0036] (2) Convert the dental model into an STL model or a three-dimensional CAD model and store it in the computer;

[0037] (3) Import the STL model or 3D CAD model into the 3D CAD design software, take the arch wire plane, draw the CAD plane model of the arch wire shape on the plane according to the shape of the dental arch, and then design the personalized design according to the STL model or 3D CAD model The base plate of the retainer, and then design the retainer groove according to the drawn arch wire shape and direction, and finally obtain a complete retainer CAD model;

[0038] (4) Import the CAD model of the retainer into the wax-type machine to make the wax-type retainer;

[0039] (5) Precision casting the wax type of the retainer, and performing surface treatment on the cast retainer according to clini...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com