Electric main shaft of digital control machine tool

A technology of CNC machine tools and electric spindles, applied in the direction of electromechanical devices, mechanical energy control, electrical components, etc., can solve the problems of unreplaceable bearings, spindle damage, unfavorable precision machining, etc., to reduce manufacturing and use costs, facilitate assembly and disassembly, Facilitate the effect of precision machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

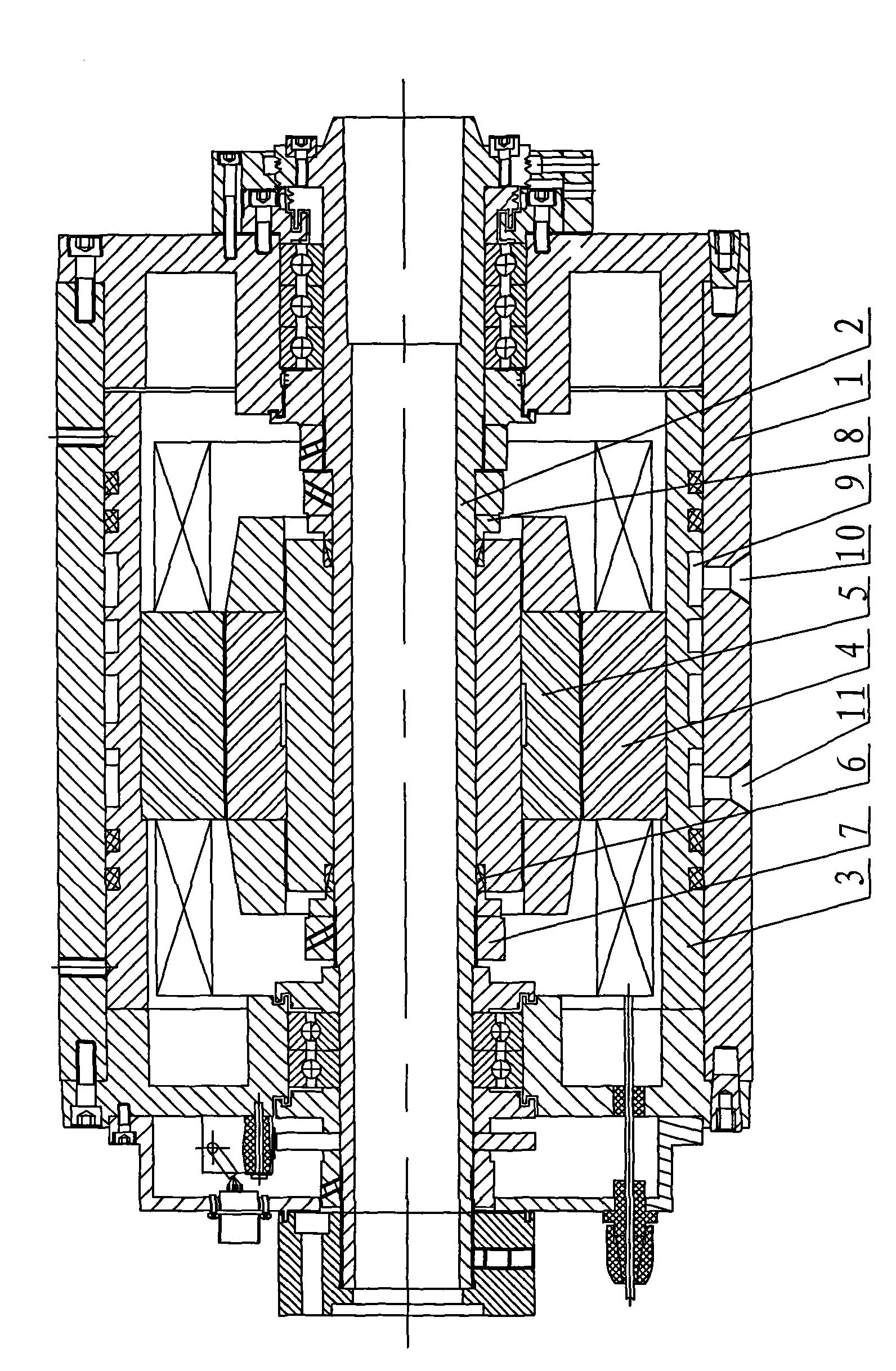

[0011] Example: such as figure 1 As shown, an electric spindle of a CNC machine tool includes a spindle 2 and a motor arranged in a box body 1. The motor includes a housing 3 and a rotor 4. The rotor 4 is inserted into the spindle 2 and is located in the middle of the spindle 1. The rotor 4 passes through the expansion The tightening device is connected with the main shaft 2.

[0012] The tensioning device in this example includes a spacer 5 arranged between the rotor 4 and the main shaft 2, and an expansion sleeve 6 is arranged at both ends of the spacer 5, and the above-mentioned expansion sleeve 6 is pressed into the space between the spacer 5 and the main shaft 2 In the gap, a lock nut 7 is arranged on the outside of the expansion sleeve 6, and the above lock nut 7 compresses the expansion sleeve 6 through the pressure spacer 8.

[0013] A circulating water channel 9 is arranged in the casing 3 , and the above-mentioned circulating water channel 9 is arranged laterally in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com