Gear oil pump with low noise

A gear oil pump, low-noise technology, applied to pumps, pump components, rotary piston pumps, etc., can solve problems affecting the normal lubrication of motor vehicle running parts, gear oil pump flow and pressure pulsation, and affect the service life of running parts, etc., to achieve Improve transmission and working efficiency, good mesh sealing, convenient and simple maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

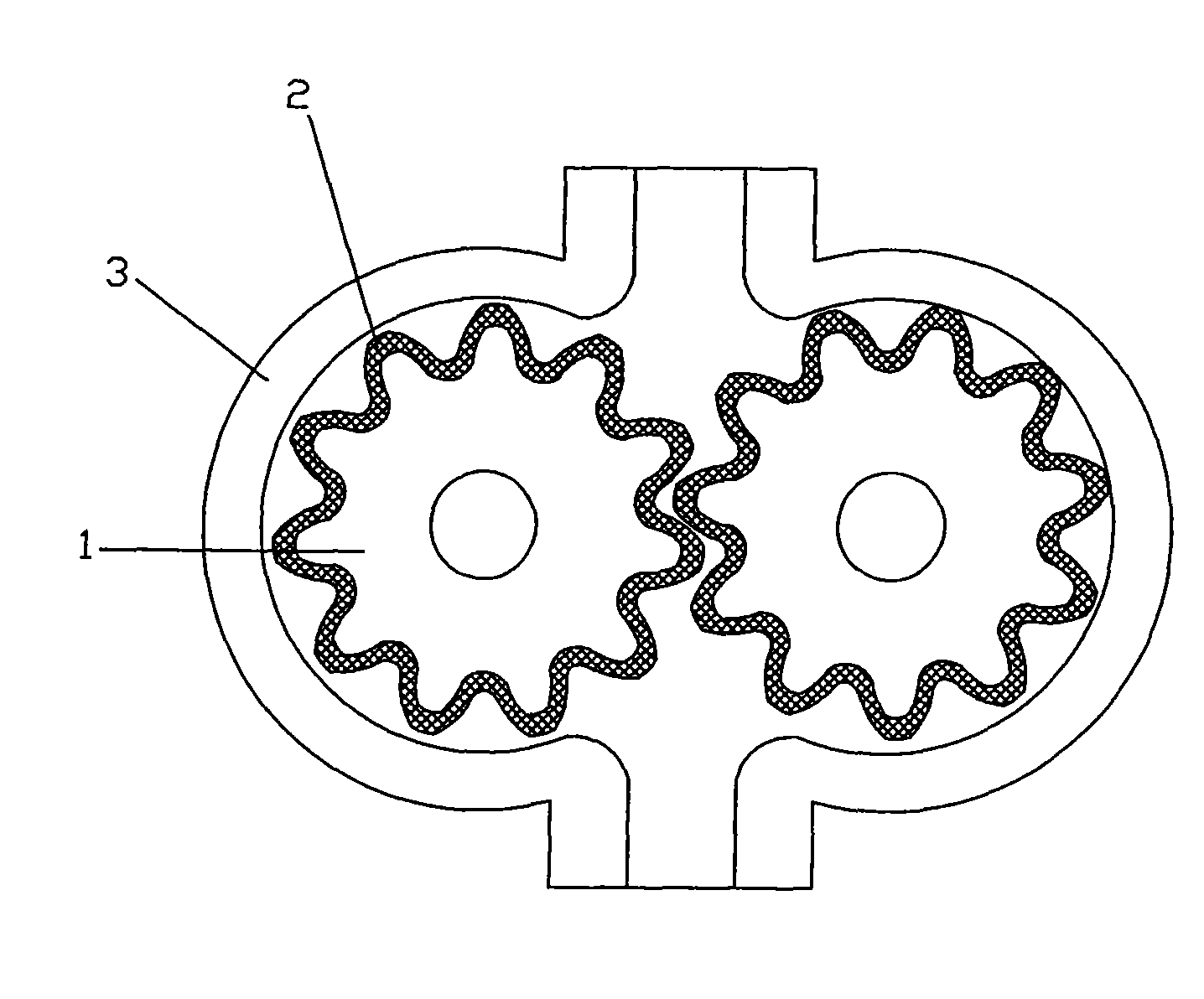

[0016] The accompanying drawing is a schematic structural diagram of the present invention, as shown in the figure: the low-noise gear oil pump of this embodiment includes a pump cylinder 3 and two gears 1 that are engaged with each other in the pump cylinder 3, and the tooth surfaces of the two gears 1 are Secure the cover elastic2.

[0017] In this embodiment, the material of the elastic layer 2 is filled polytetrafluoroethylene; it has good oil resistance, wear resistance, and self-lubricating performance, and is suitable for a motor vehicle lubricating oil pump.

[0018] In this embodiment, metal powder is added to the filled polytetrafluoroethylene to further increase the wear resistance and improve the service life of the oil pump.

[0019] Of course, the material of the elastic layer 2 is a resin-based elastic oil-resistant and wear-resistant material; it has high strength and improves the ability of the elastic layer to resist impact loads, which can also achieve the p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap