16-step dual-frequency grating phase shift profilometry capable of absolute phase unwrapping

A dual-frequency grating and phase technology, applied in the field of optical three-dimensional sensing, can solve the problems that the measurement accuracy and measurement range cannot be guaranteed at the same time, and achieve the effects of suppressing the accumulation of error diffusion, strong adaptability, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and working principles.

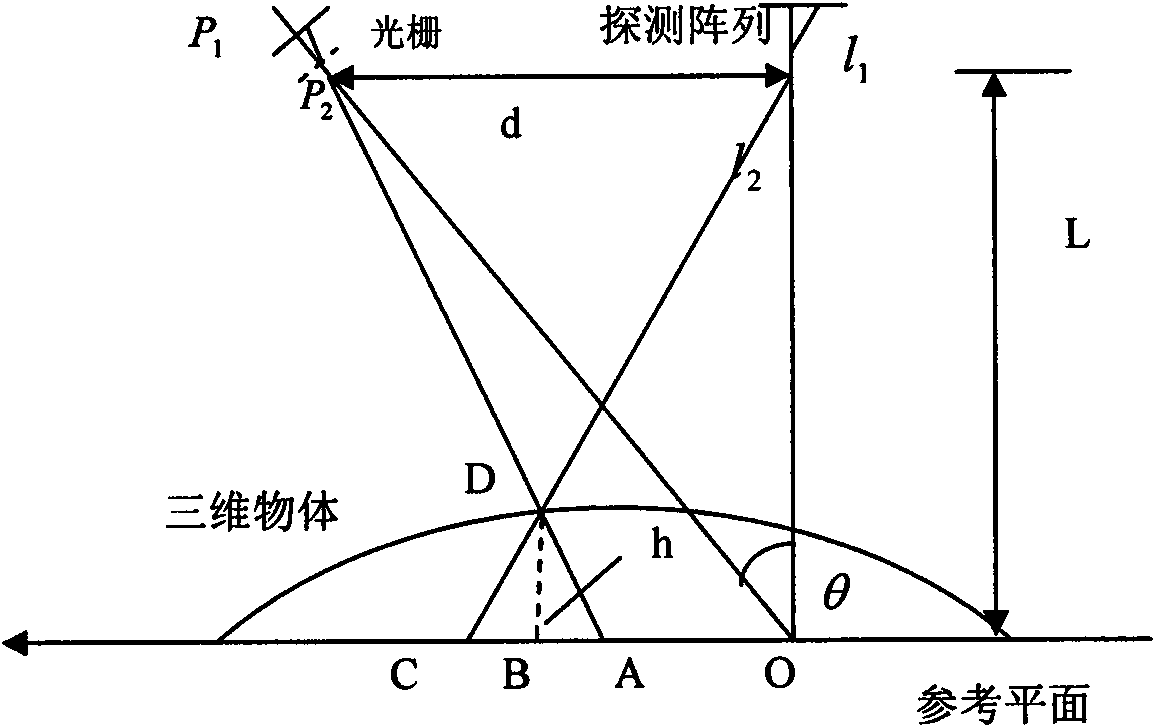

[0016] The optical path of real-time three-dimensional surface measurement with dual-frequency grating is similar to that of traditional phase measurement profilometry. figure 1 is the projection light path of the PMP method, P 1 and P 2 are the entrance pupil and exit pupil of the projection system, I 2 and I 1 are the entrance and exit pupils of the imaging system. The imaging optical axis is perpendicular to the reference plane, and the included angle with the projection optical axis is θ, they intersect at point O on the reference plane, d is the distance between the optical center of the detector and the optical center of the projection device, l is the detector light The distance from the center to the reference plane.

[0017] The measurement model using non-integer multiple double-frequency grating projection, the measureme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com