External pressure self-intensification cylinder and design calculation and manufacturing method thereof

A manufacturing method, design and calculation technology, applied in the direction of calculation, pressure vessels, mechanical equipment, etc., can solve problems such as cumbersome, inner layer compression yielding, roughness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

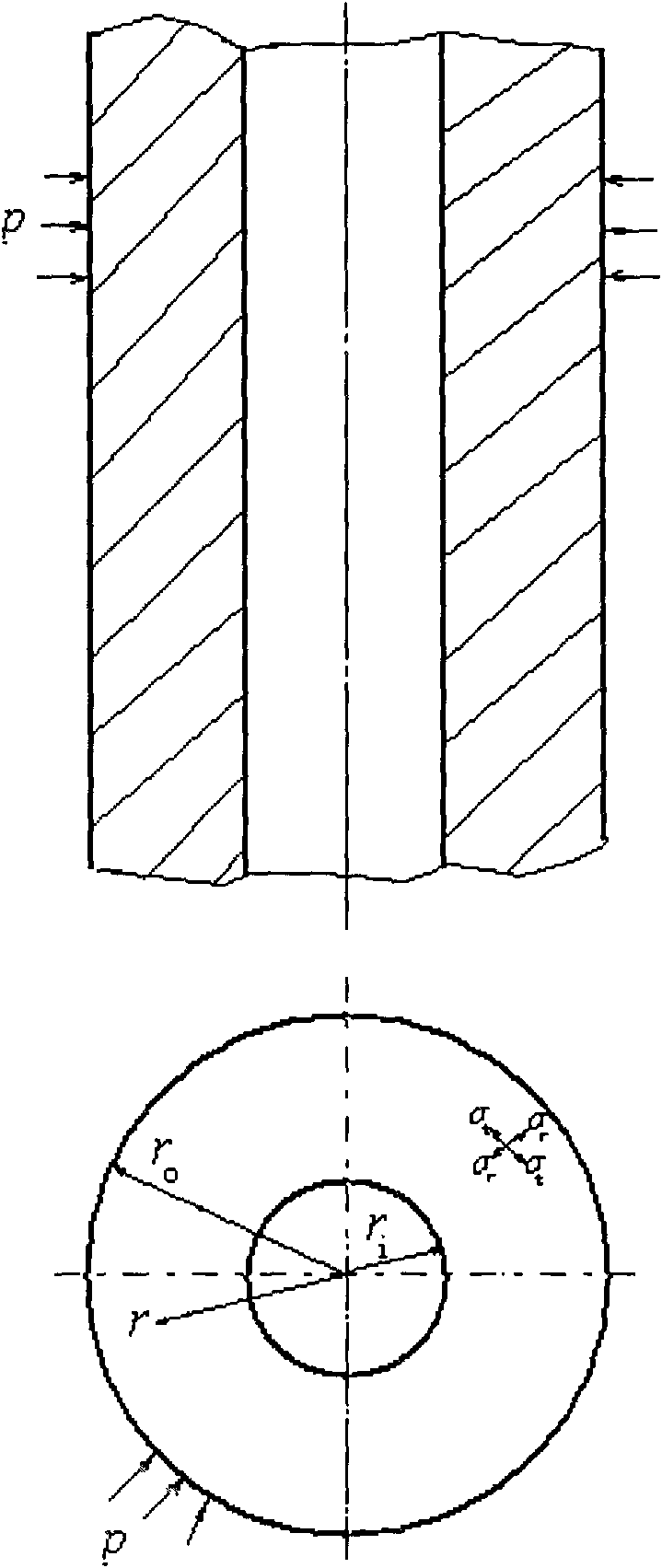

[0238] Example 1, a certain external pressure high-pressure vessel adopts self-reinforcing technology, and the inner diameter is r i =150mm; container material is 34CrNi3MoA, its σ y = 700Mpa; the external pressure to bear is p = 360Mpa; according to the relevant industry's design specifications for containers, the safety factor is taken as n = 1.6.

[0239] The calculated thickness of the container can be calculated immediately from formula (55):

[0240] t = r i ( σ y σ y - np - 1 ) = 150 ( 700 700 - 1.6 ...

Embodiment 2

[0248] Example 2, assuming that the process calculation determines the inner diameter of the pressure vessel r i =500mm; the container material is 20MnMoNb, its σ y =480Mpa; the required external pressure p=100Mpa; the safety factor is n=1.6.

[0249] The calculated thickness of the container can be calculated immediately from formula (55):

[0250] t = r i ( σ y σ y - np - 1 ) = 500 ( 480 480 - 1.6 × 100 - 1 ) ...

Embodiment 3

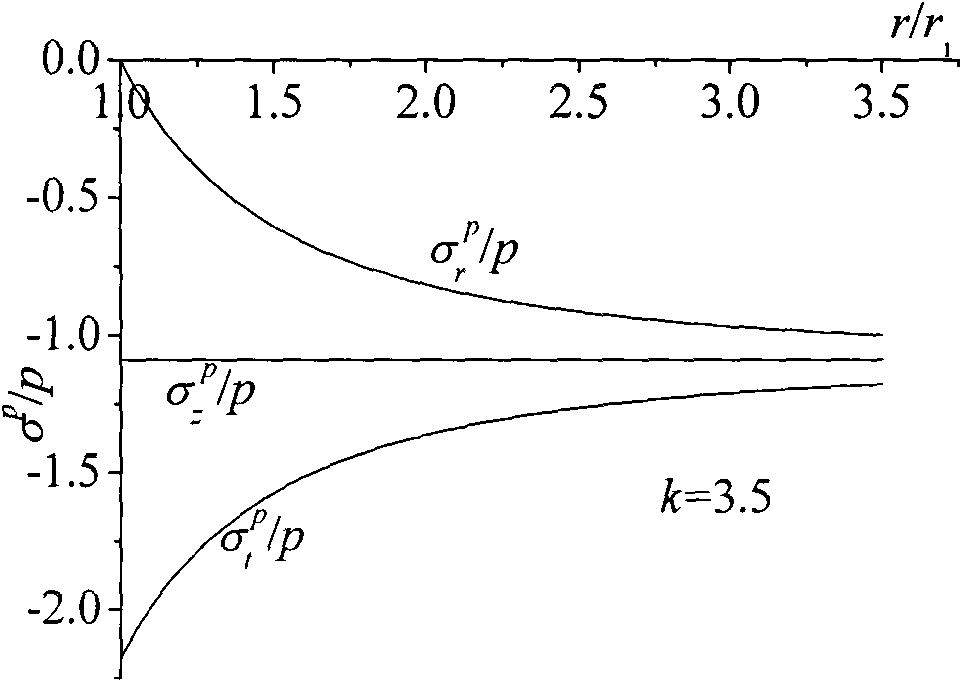

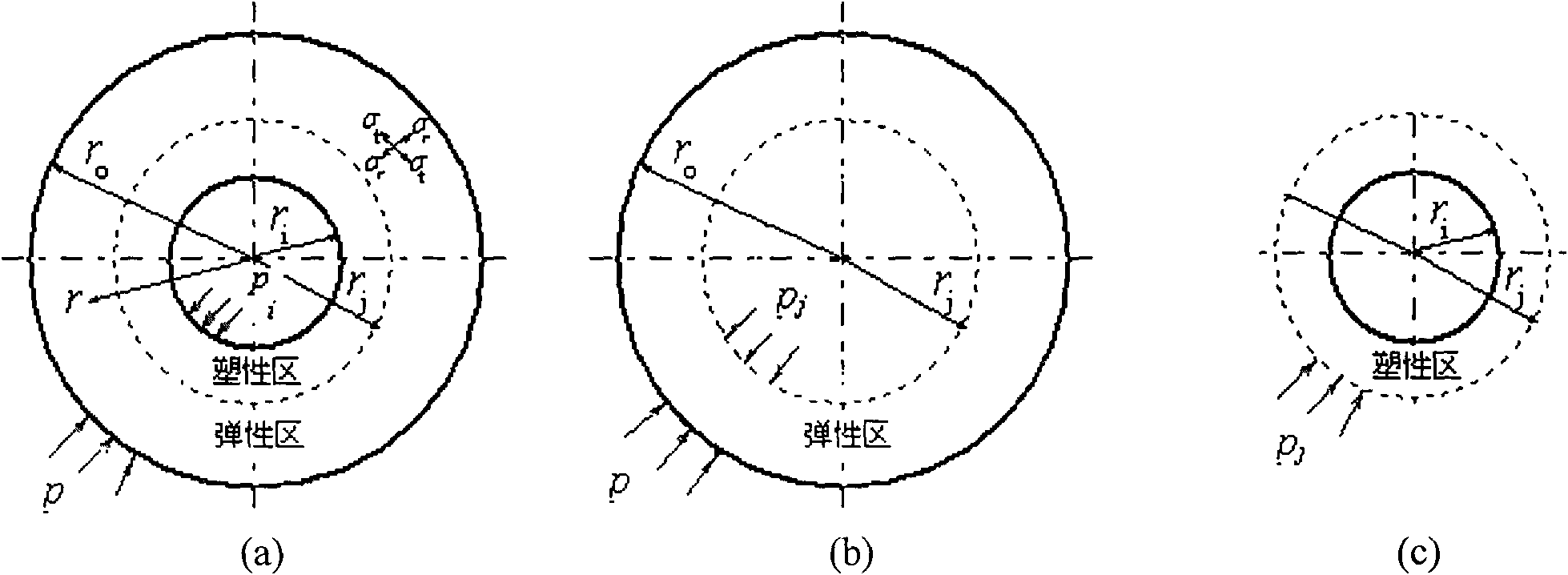

[0266] Example 3, there is a self-reinforcing container with diameter ratio k=2.5, made of 20MnMoNb, σ y = 480 MPa. It is necessary to determine the load that the container can withstand.

[0267] According to the fourth intensity theory. By formula (45') or Figure 15 Get: the best carrying capacity p * / σ y = 0.969948, ie p * =0.969948×480=465.5753Mpa, take safety factor n=1.6, then p=465.5753 / 1.6=290.9845Mpa. Look up table 1 and know, when k=2.5, k j * = 1.844363 . When the container bears an external pressure of 290.9845Mpa, there must be σ′ ei = σ y , σ in the entire plastic zone e T y . verify:

[0268] According to formula (30): σ ei ′ σ y = k 2 l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com