Edible fungi sterilization and inoculation integrated equipment

A technology for sterilizing inoculation and edible fungi, applied in botany equipment and methods, applications, gardening, etc., can solve the problems of low automation of edible fungus mechanical equipment, low inoculation success rate, and easy contamination, so as to eliminate human factors interference, high inoculation success rate, and reduced production links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

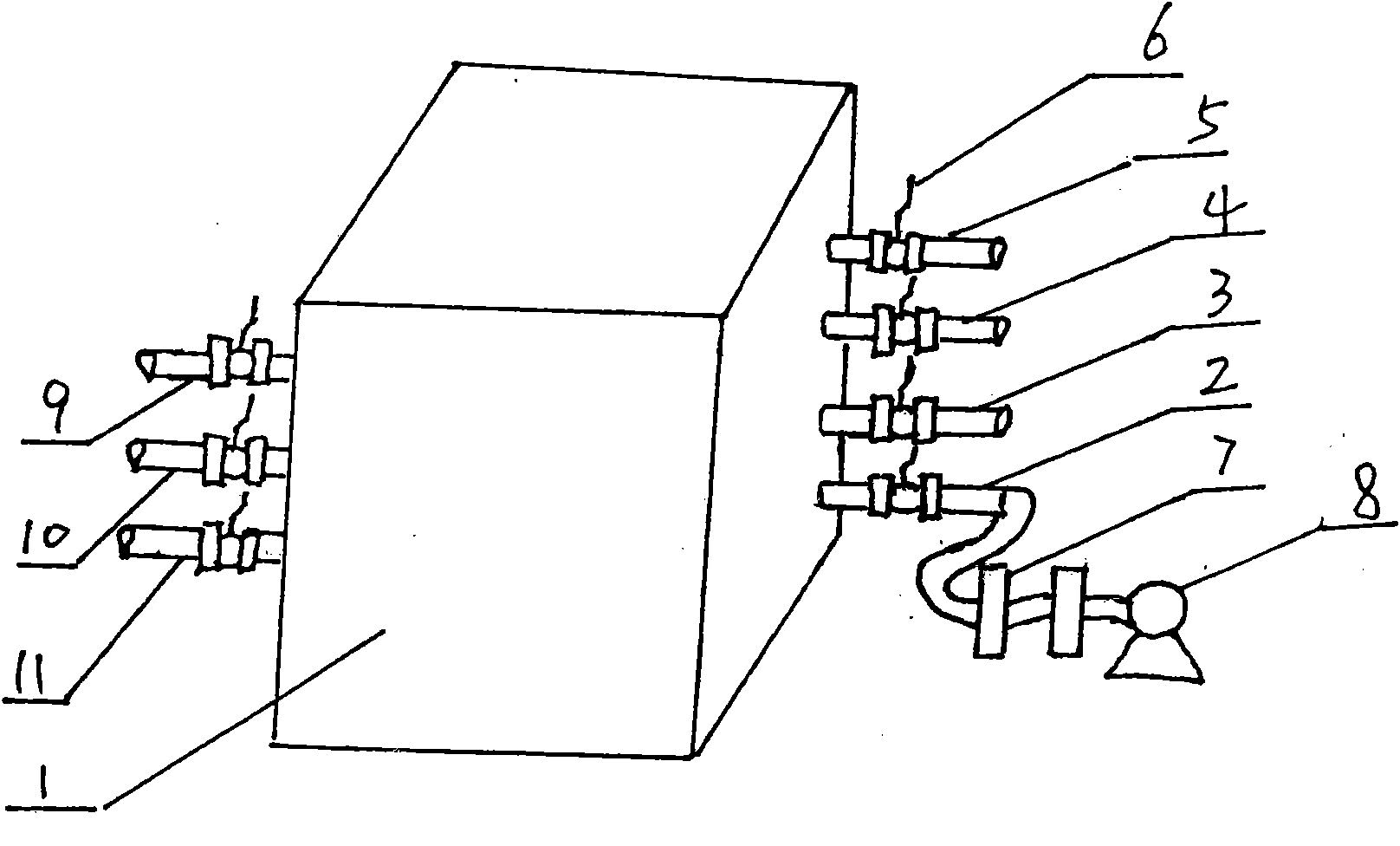

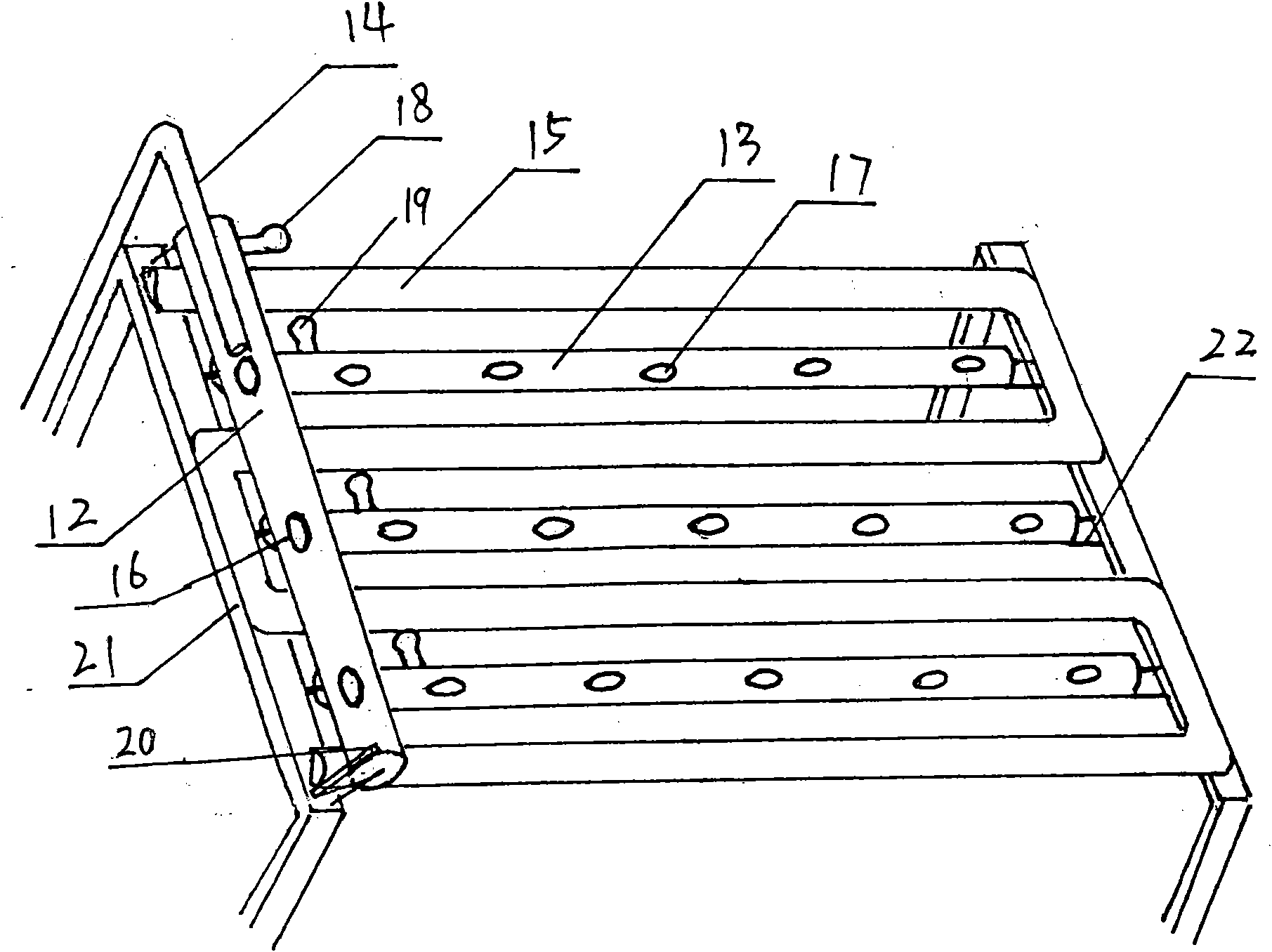

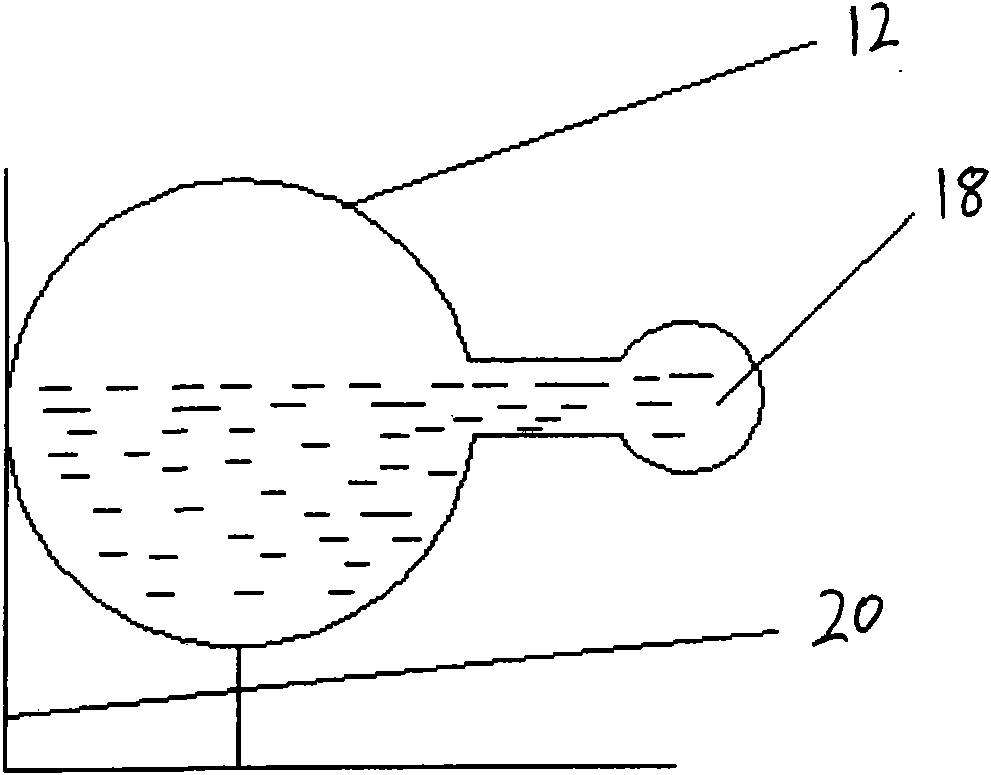

[0014] An integrated equipment for sterilization and inoculation of edible fungi, comprising a fermenter for liquid strains, a closed sterilization chamber 1, connected to the outside of the sterilization chamber 1 is a steam inlet pipe 3, a steam exhaust pipe 10, a water inlet pipe 4, and a drain pipe 9 , strain pipe 5, air inlet pipe 2 and air exhaust pipe 11, air inlet pipe 2 is connected with air filter 7, and air filter 7 is connected to blower fan 8, and described each nozzle place is respectively provided with control valve 6 ; Sterilization chamber 1 is provided with a multi-layered support frame 21, and each layer of support frame 21 is respectively provided with a bent water circulation pipe 15, and the two ends of the water circulation pipe 15 are respectively connected with the water inlet pipe 4 and the drain pipe 9; A plurality of auxiliary inoculation pipes 13 are arranged between the adjacent water circulation pipes 15, and main inoculation pipes 12 are arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com