System for automatically producing metal ingot stack

A technology for automatic production and metal ingots, applied in metal processing equipment, safety devices, manufacturing tools, etc., to achieve the effects of enhancing processing capacity, solving easy torsion damage, and solving technical bottlenecks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

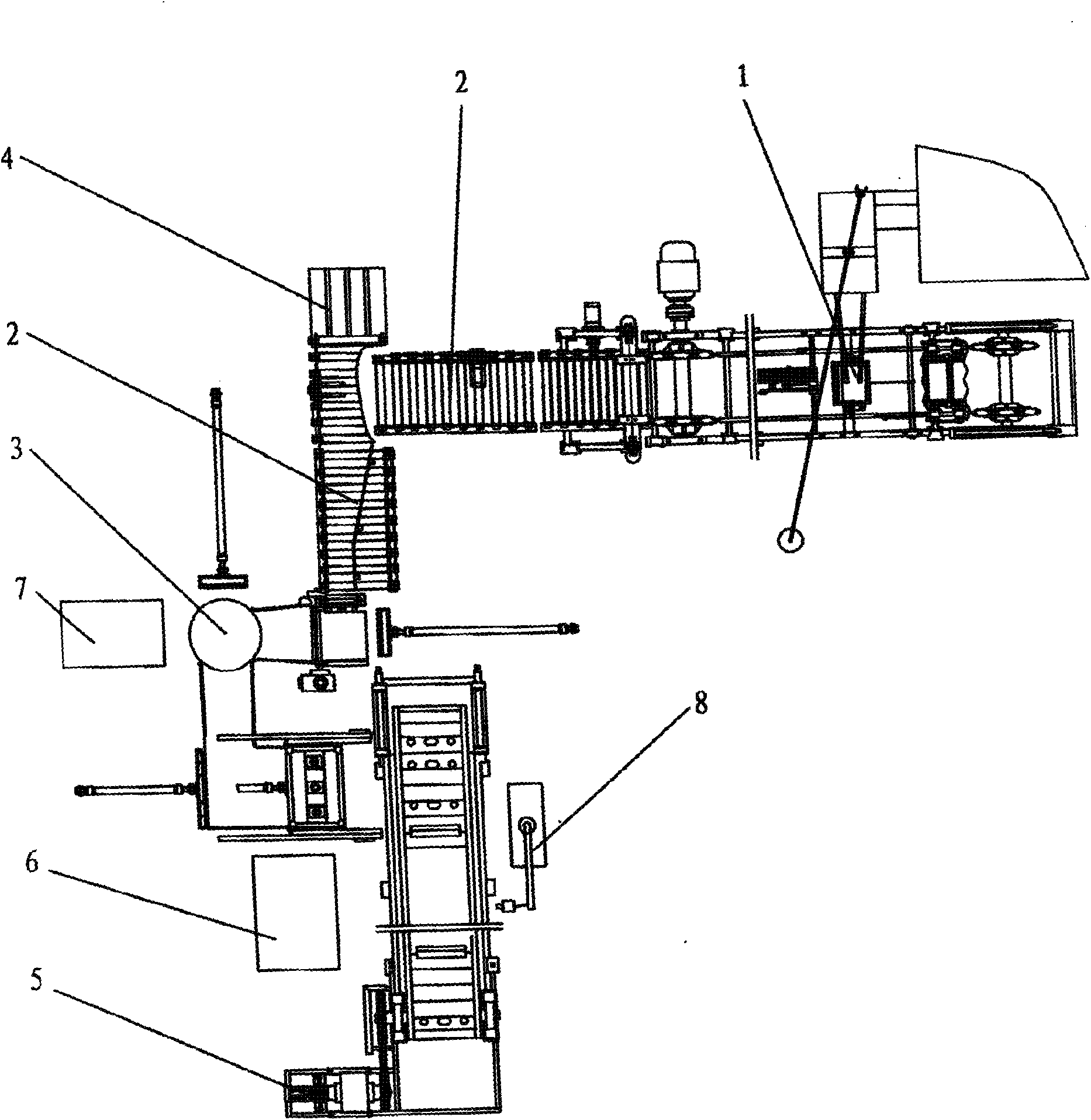

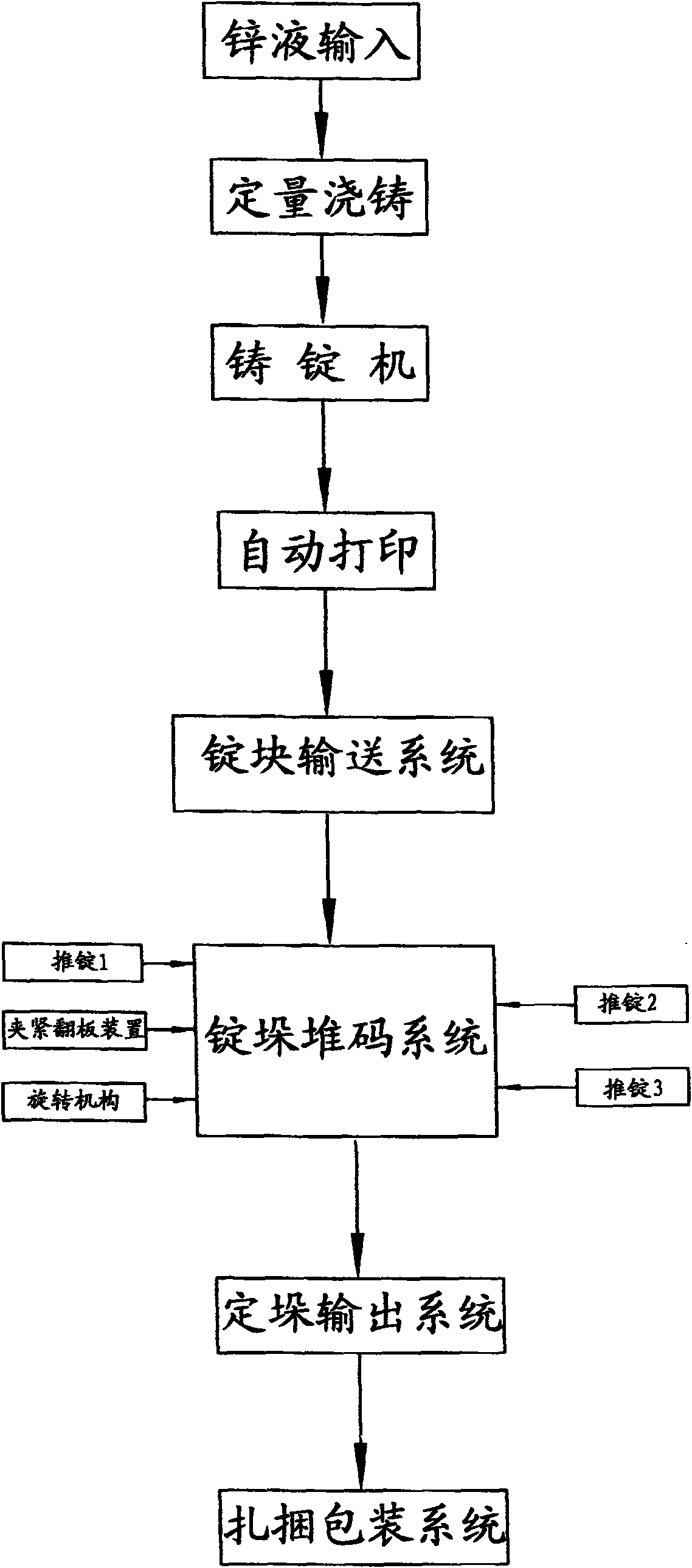

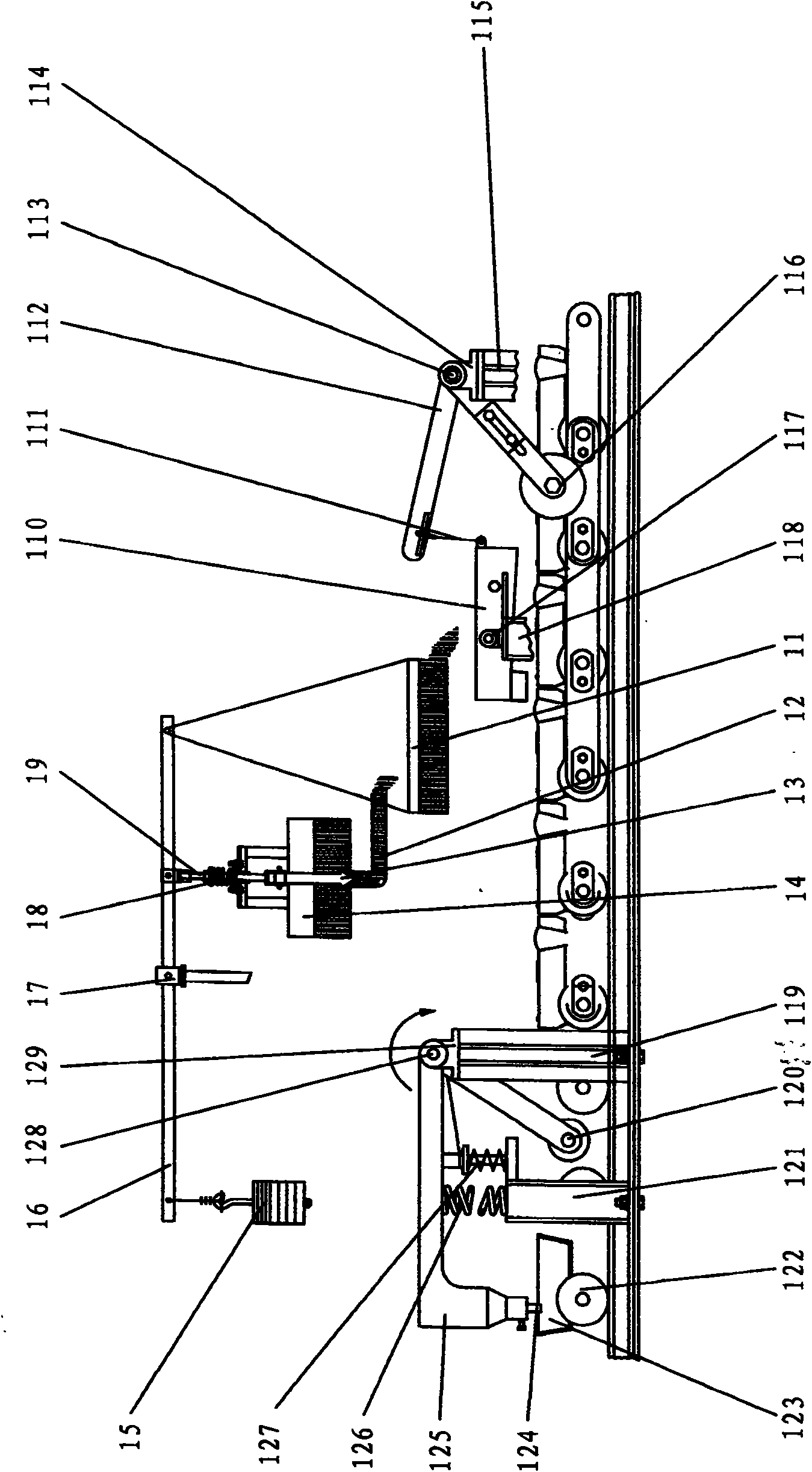

[0023] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , an automatic production system for metal ingot stacks, including an automatic ingot production system 1, an ingot conveying system 2, an ingot stacking system 3, a manual stacking system 4, an ingot stack output system 5, a hydraulic transmission system 6, and an electrical control system In system 7 and bundling packaging system 8, the metal liquid flows out from the melting furnace or the liquid holding furnace, and the quantitative casting is realized by the automatic flow control device in the ingot automatic production system 1, and is cast on the ingot casting machine, and is formed by the ingot casting machine. The printing device linked with the ingot machine automatically prints the batch number, date and other marks, and forms a square pyramid-shaped metal ingot with a draft angle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com