Method for extracting and purifying medical polysaccharide of large leaf moss

A technology of Huixin grass and polysaccharide, which is applied in the direction of drug combination, cardiovascular system diseases, etc., can solve the problems of less Huixin grass and no extraction of Huixin grass polysaccharide, etc., and achieves the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

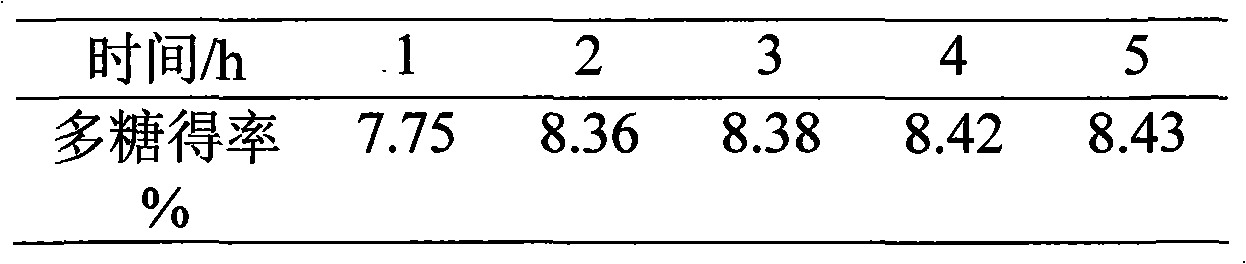

[0019] (1) Investigate the effect of extraction time on the extraction rate: crush the Herba Sinensis, pass through 60 meshes, put in an ultrasonic extractor, add 20 times of water, adjust the pH to 8-9, raise the temperature to 90°C, and extract separately Three extracts were combined at different times. After centrifuging for 15 minutes, take the clear liquid; concentrate the extract to a certain volume under reduced pressure, remove the protein by savage method, then add edible ethanol to make the concentration reach 80%, and the resulting precipitate is refined, dried in vacuum, and crushed to obtain the polysaccharide Boutique. The extraction rate is shown in Table 1: it can be seen that the extraction time of 2 hours can meet the requirements.

[0020] Table 1 The influence of extraction time on polysaccharide yield

[0021]

Embodiment 2

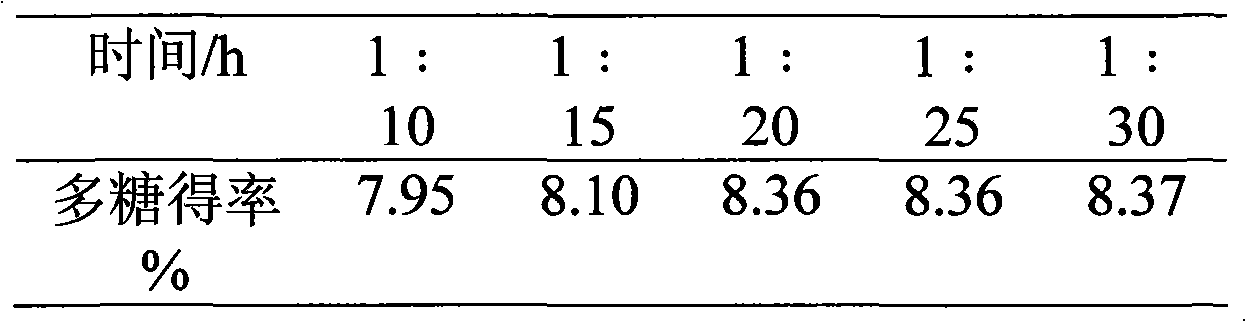

[0023] Investigate the effect of solid-liquid ratio on the extraction rate: crush the Herba Sinensis, pass through 60 meshes, place it in an ultrasonic extractor, add different multiples of water, adjust the pH to 8-9, raise the temperature to 90°C, and extract for 2 hours , combined three extracts. After centrifuging for 15 minutes, take the clear liquid; concentrate the extract to a certain volume under reduced pressure, remove the protein by savage method, then add edible ethanol to make the concentration reach 80%, and the resulting precipitate is refined, dried in vacuum, and crushed to obtain the polysaccharide Boutique. The extraction rate is shown in Table 2: It can be seen that the solid-liquid ratio is 1:20-30. Considering that the subsequent process steps will be concentrated and the cost will be increased, it is more economical to choose 1:20.

[0024] The influence of table 2 solid-liquid ratio on polysaccharide yield

[0025]

Embodiment 3

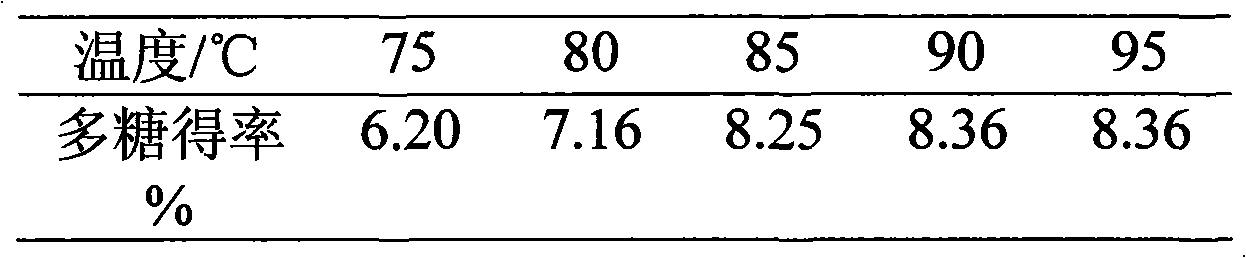

[0027] Investigate the effect of extraction temperature on the extraction rate: crush the Herba huixin, pass through 60 meshes, put it in an ultrasonic extractor, add 20 times of water, adjust the pH to 8-9, extract at different temperatures for 2 hours, and combine three extractions liquid. After centrifuging for 15 minutes, take the clear liquid; concentrate the extract to a certain volume under reduced pressure, remove the protein by savage method, then add edible ethanol to make the concentration reach 80%, and the resulting precipitate is refined, dried in vacuum, and crushed to obtain the polysaccharide Boutique. The extraction rate is shown in Table 3: it can be seen that the yield is the highest when the extraction temperature is 90°C.

[0028] Table 3 The influence of extraction temperature on polysaccharide yield

[0029]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com