Multi-nozzle high-efficiency large capacity inclined jet turbine

One-type hydraulic turbine, high-capacity technology, applied in the field of fluid machinery, can solve the problems of inconvenient disassembly, maintenance, small output per unit, small overflow, etc., to achieve convenient disassembly and maintenance, reduce the number of units, and improve runner efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

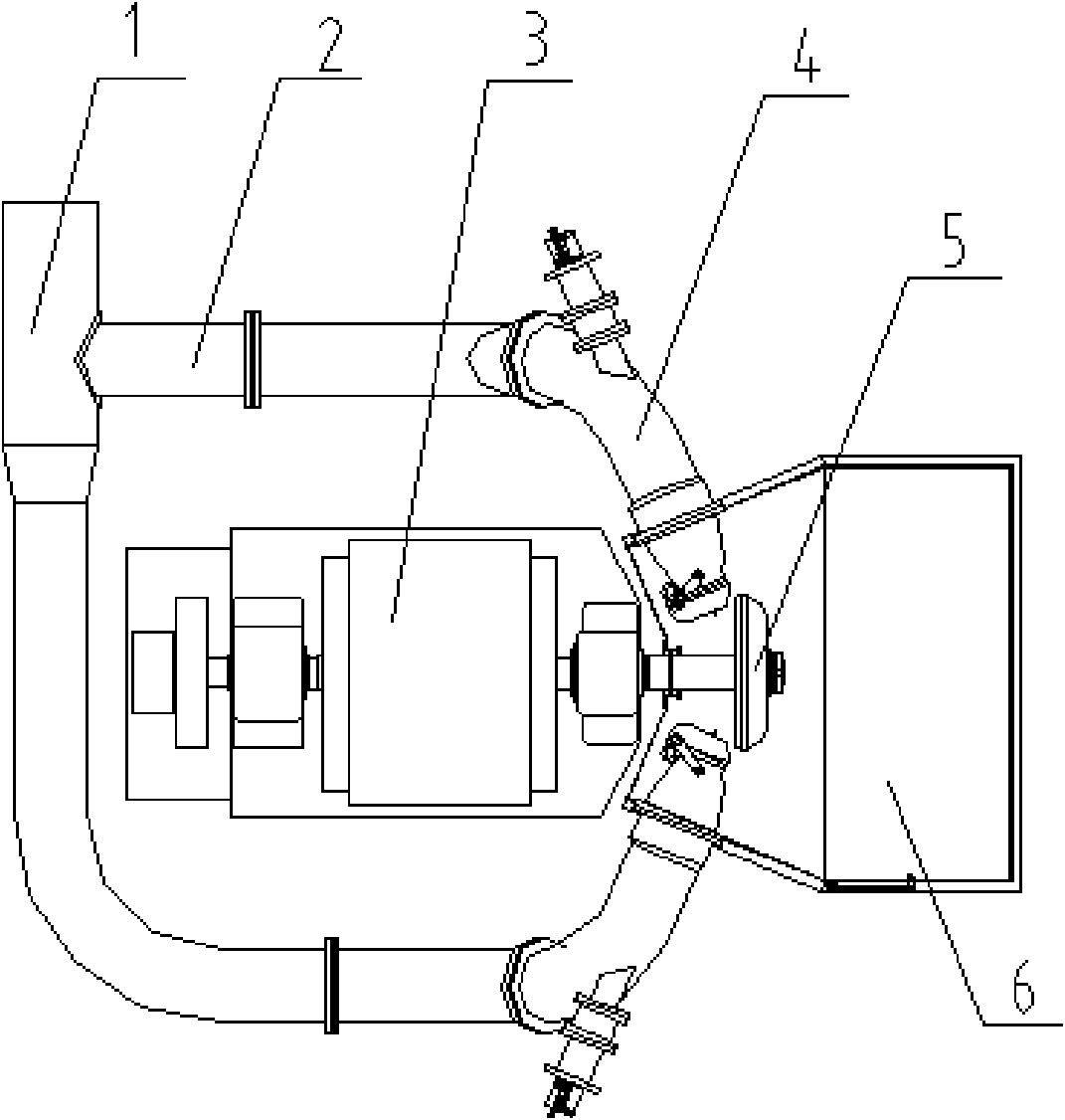

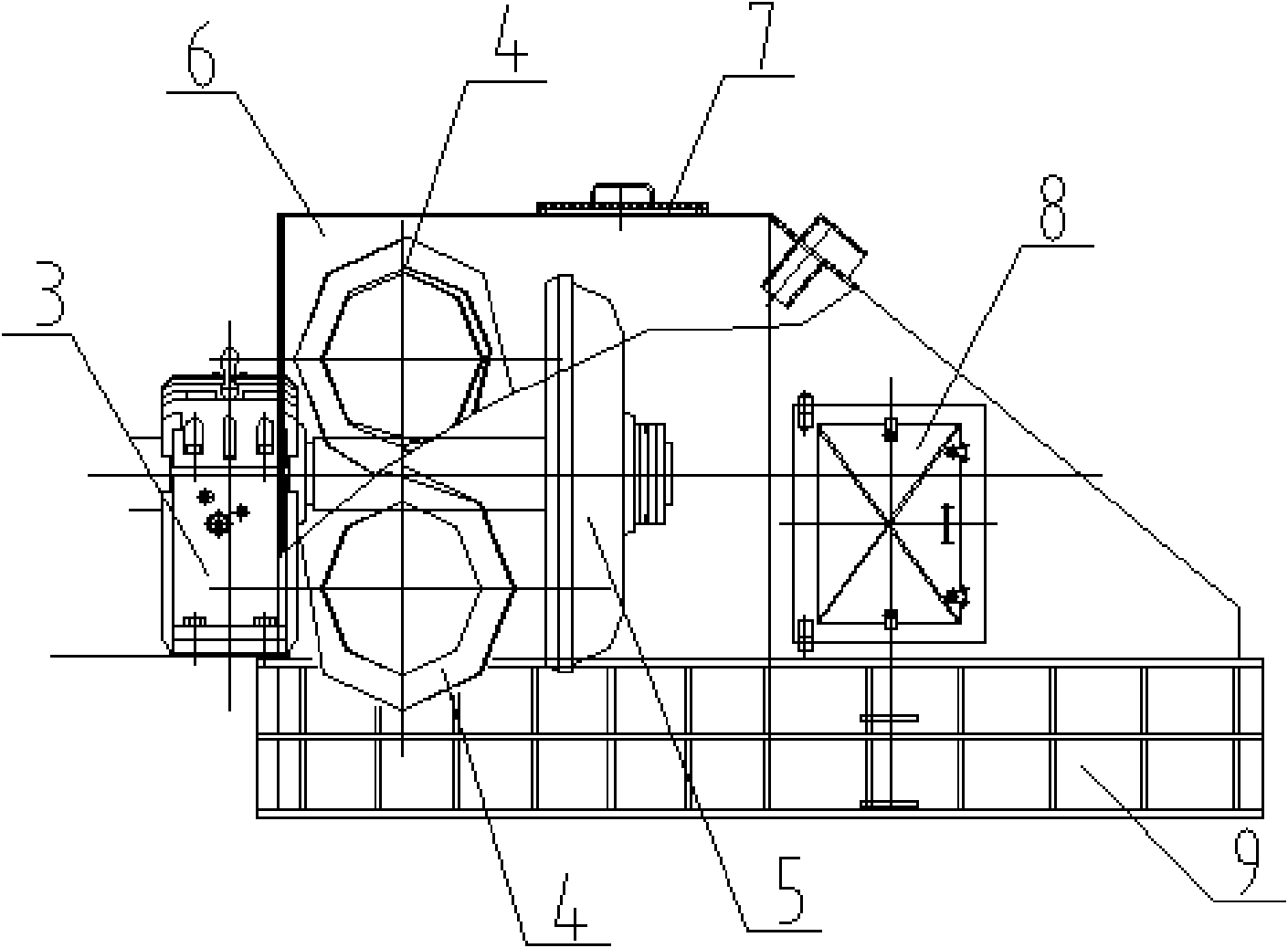

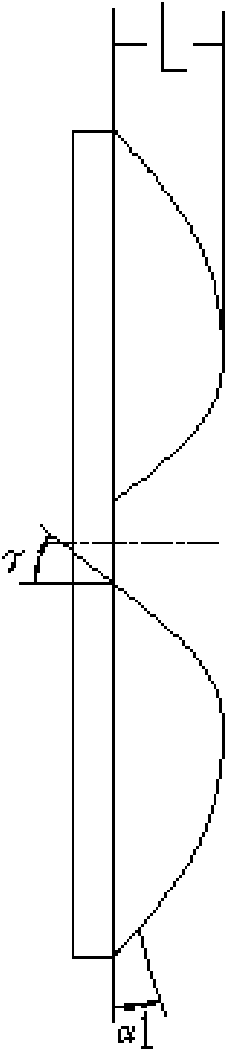

[0017] see figure 1 -- image 3 , the present invention comprises a water diversion ring pipe 1, a casing 6, a nozzle 4, a runner 5 and a motor 3 in the casing. The key technology is to install two nozzles 4 on the water diversion ring pipe 1 to align with the runner 5, the angle between each nozzle and the runner inlet plane is 21°, the jet inlet angle α1 is 21°, and the runner outlet width L is more traditional The width of the runner outlet of the single-nozzle slanting impact turbine is increased by 25%, and the placement angle γ of the runner outlet is 15°. A branch pipe 2 is connected to a nozzle 4 on the water diversion ring pipe 1 .

[0018] In the prior art, it is generally necessary to remove the machine cover or move the unit when dismantling and changing the runner, which brings inconvenience to maintenance. The present invention is provided with a runner hoisting hole 7 at the upper end of the casing 6, and usually uses a cover to cover the runner hoisting hole....

Embodiment 2

[0020] see figure 1 -- image 3 , the present invention comprises a water diversion ring pipe 1, a casing 6, a nozzle 4, a runner 5 and a motor 3 in the casing. The key technology is to install two nozzles 4 on the water diversion ring pipe 1 to align with the runner 5, the angle between each nozzle and the runner inlet plane is 20°, the jet inlet angle α1 is 20°, and the runner outlet width L is more traditional The width of the runner outlet of the single-nozzle slanting impact turbine is increased by 28%, and the placement angle γ of the runner outlet is 16°. A branch pipe 2 is connected to a nozzle 4 on the water diversion ring pipe 1 . The upper end of the casing 6 is provided with a runner hoisting hole 7, one side of the casing 6 is provided with an entry door 8, and the bottom of the casing 6 is provided with a horizontal water grid 9.

Embodiment 3

[0022] see figure 1 -- image 3 , the present invention comprises a water diversion ring pipe 1, a casing 6, a nozzle 4, a runner 5 and a motor 3 in the casing. The key technology is to install two nozzles 4 on the water diversion ring pipe 1 to align with the runner 5, the angle between each nozzle and the runner inlet plane is 19°, the jet inlet angle α1 is 19°, and the runner outlet width L is more traditional The width of the runner outlet of the single-nozzle slanting impact turbine is increased by 30%, and the placement angle γ of the runner outlet is 16°. A branch pipe 2 is connected to a nozzle 4 on the water diversion ring pipe 1 . The upper end of the casing 6 is provided with a runner hoisting hole 7, one side of the casing 6 is provided with an entry door 8, and the bottom of the casing 6 is provided with a horizontal water grid 9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com