Method for separating and analyzing volatile and semi-volatile flavor components in tobacco by using liquid chromatography-gas chromatography/mass spectrometry technology

A technology of gas chromatography mass spectrometry and aroma components, which is applied in the direction of material separation, material analysis, measuring devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

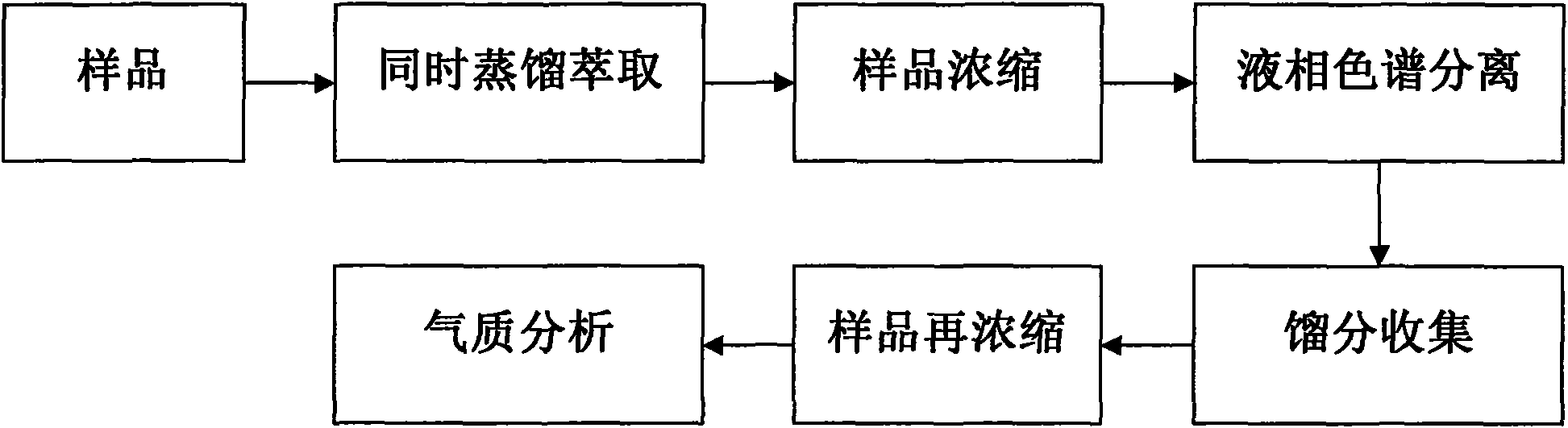

Method used

Image

Examples

Embodiment

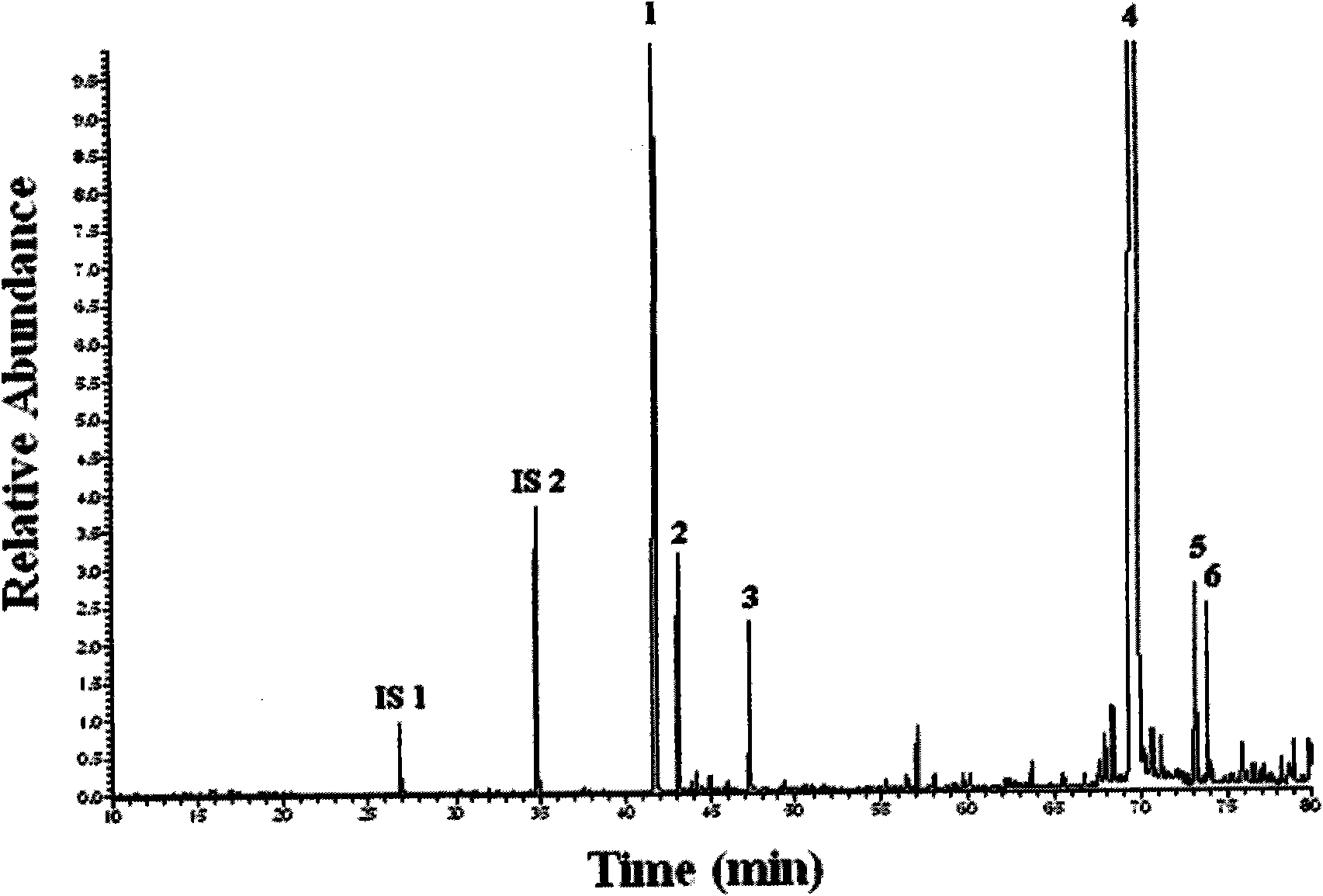

[0029] Examples Tobacco powder

[0030] 1. At the same time, one end of the distillation extraction device is connected to a 1000mL flat-bottomed flask containing 25g of tobacco powder, 350mL of water and 90g of sodium chloride, and is heated by an electric furnace with controllable voltage. At the same time, the other end of the distillation extraction device was connected to a 100 mL flask filled with 45 mL of dichloromethane, and this end was heated on a water bath, and the temperature of the water bath was 60°C. After the extraction was completed, 9 g of anhydrous sodium sulfate was added and dried overnight. The extract was then concentrated to 1 mL.

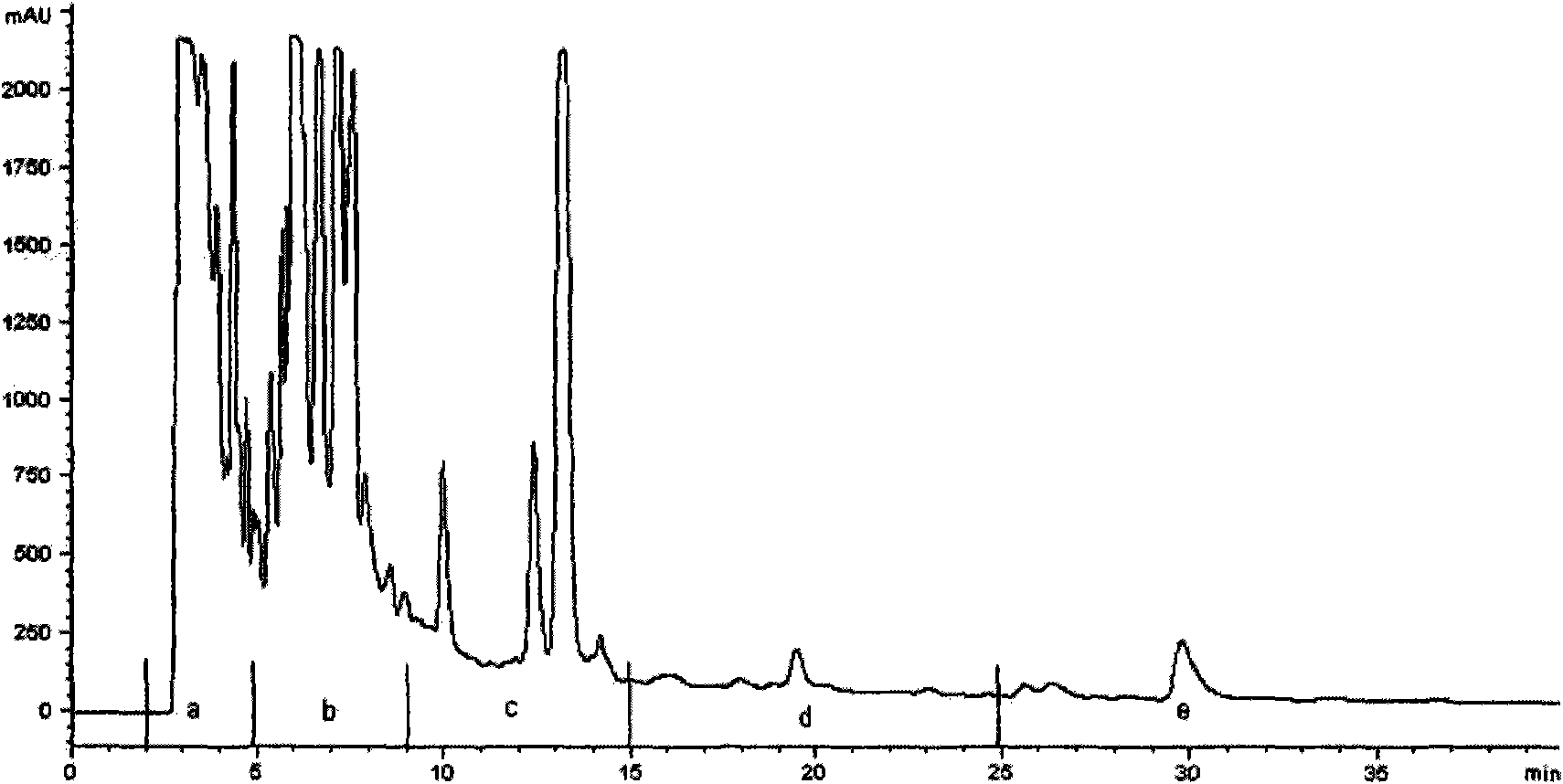

[0031] 2. The concentrated sample is separated by normal phase liquid chromatography: select amino analysis column (250mm×2.0mmi.d.), n-hexane-dichloromethane-acetonitrile (volume ratio is 90:6.6:3.4) as the mobile phase, inject the sample The volume is 5 μL, and the mobile phase flow rate is 0.2mL / min. Under this chromat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com