Motor-driven machine tool

一种马达驱动、工具机的技术,应用在制造工具、机动的其他往复式锯床、金属加工设备等方向,能够解决工具机舒适性损失等问题,达到减小振动、减小震动负荷的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

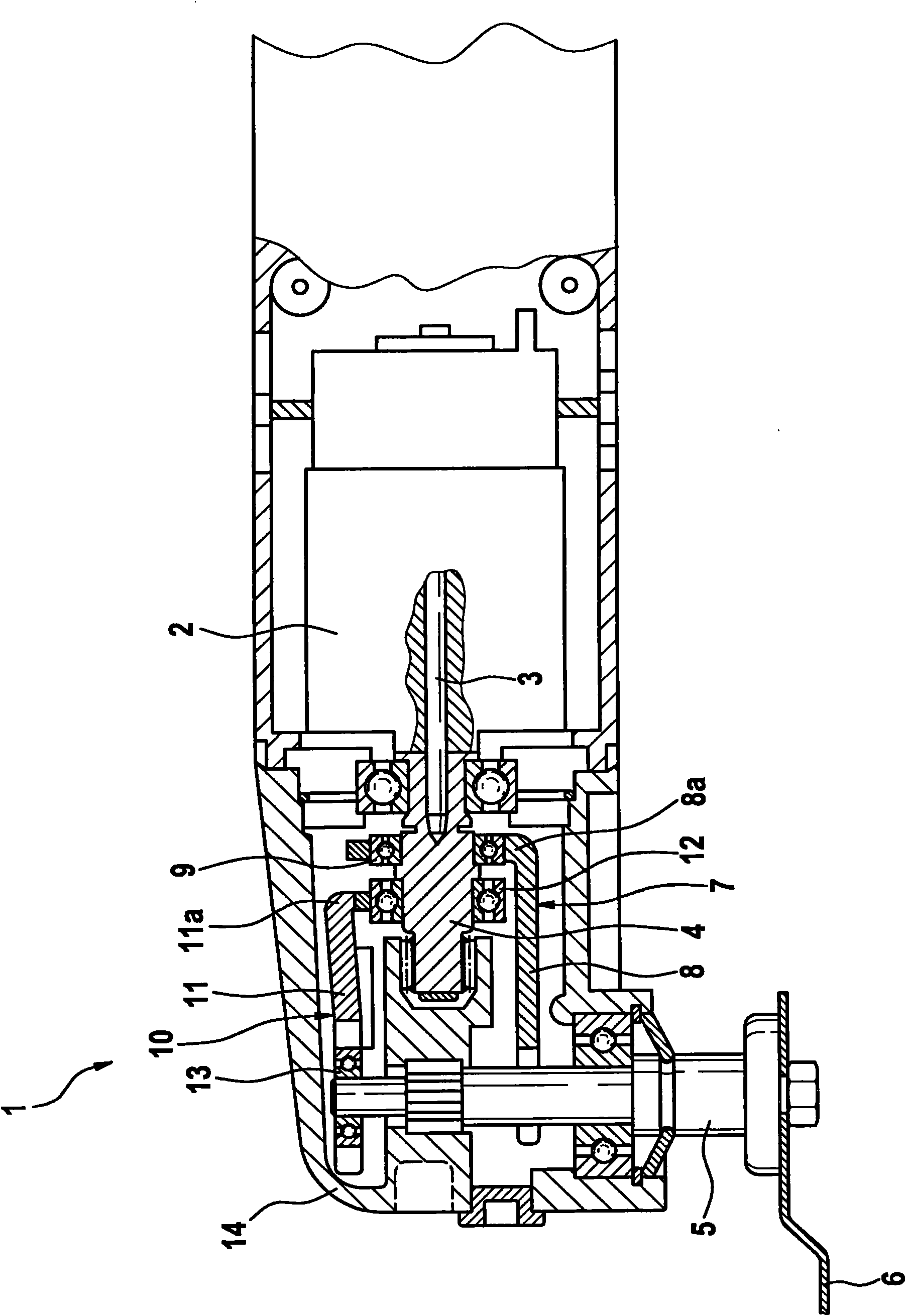

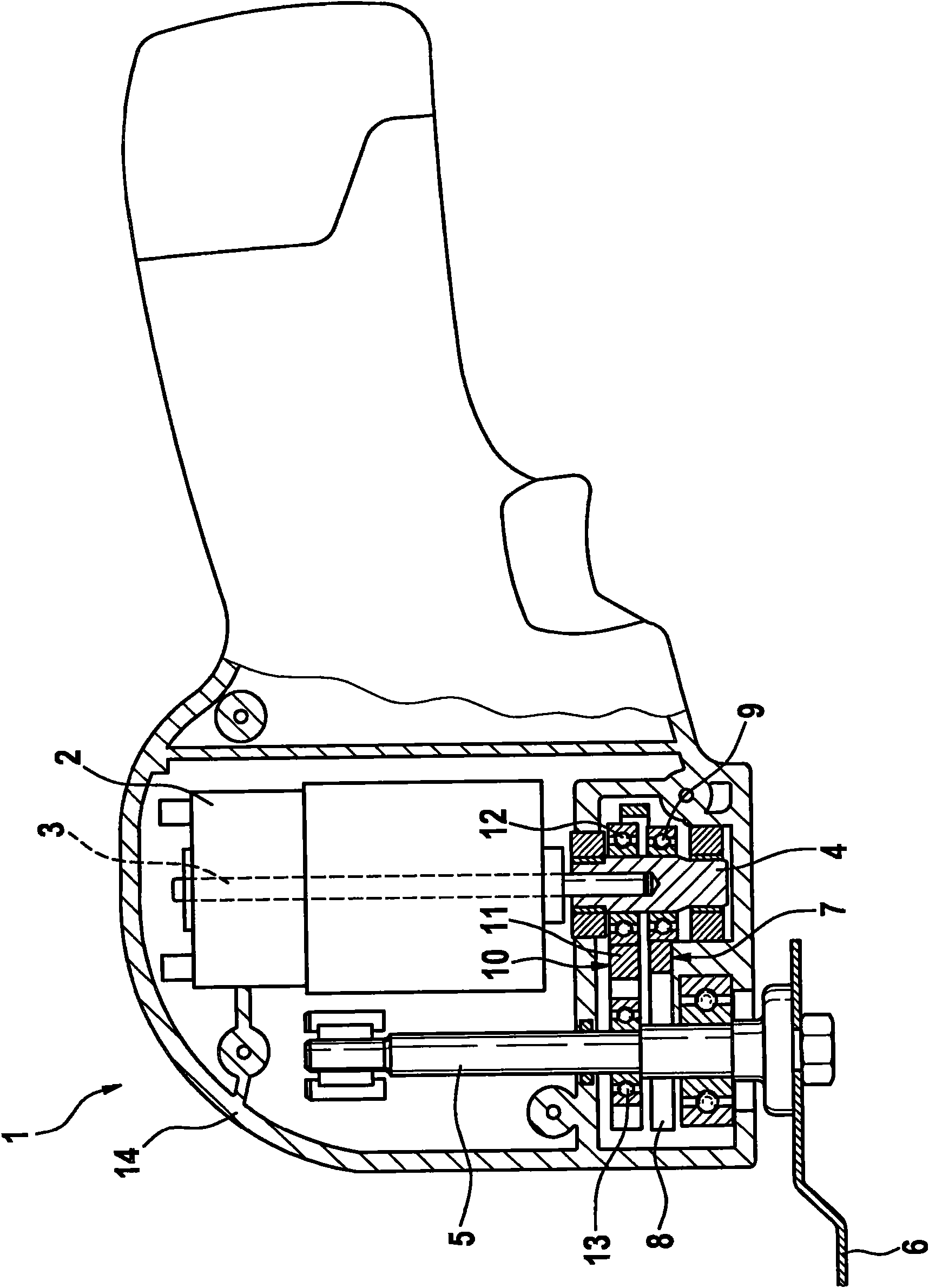

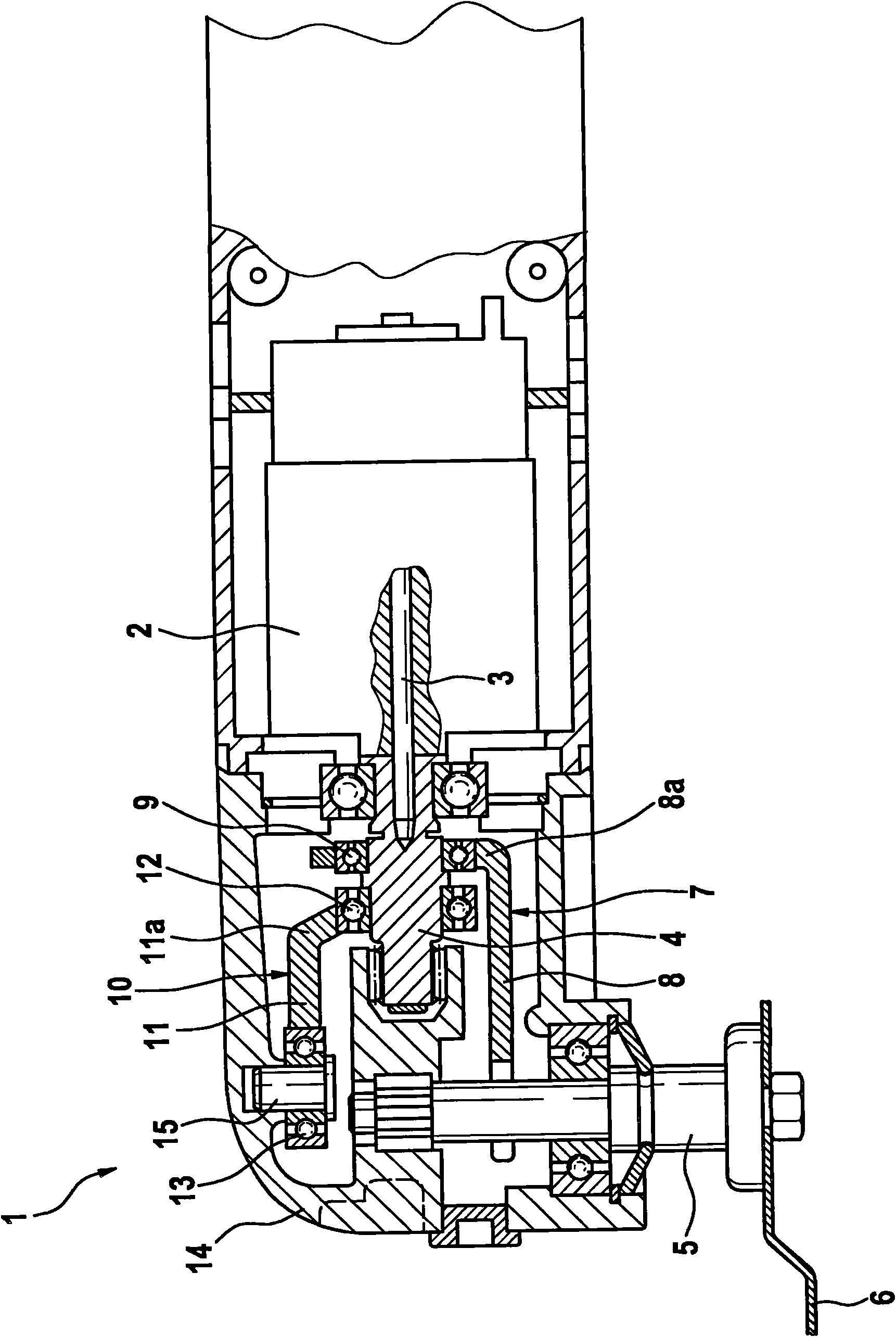

[0021] The same reference numerals are assigned to the same components in the drawings.

[0022] figure 1 The hand-held power tool 1 shown in has an electric drive motor 2, whose armature 3 is fixedly connected to a coaxial drive shaft 4, which drives the driven shaft or working shaft 5 and is mounted on the Tool 6 on driven shaft. When the electric drive motor 2 is actuated, the rotational movement of the drive shaft 4 is converted via an eccentric coupling 7 into a rotational pivoting movement of the output shaft 5 and the tool 6 , usually with an angular offset of a few degrees. The possibility thus exists for the tool 6 to be used both for grinding and for cutting or sawing a workpiece.

[0023] The eccentric coupling device 7 comprises a coupling part which is fixedly connected to the driven shaft 5 and an eccentric part which is fixedly connected to the drive shaft 4, which is designed in this embodiment as a coupling fork 8 and which is designed as an eccentric cam 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com