Robot arm

A technology of a robotic arm and a rear arm, applied in the field of double robotic arm devices, can solve the problems of complex structure, inability to easily adjust down force, low overall efficiency, etc., and achieve the effects of smooth movement, improved efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

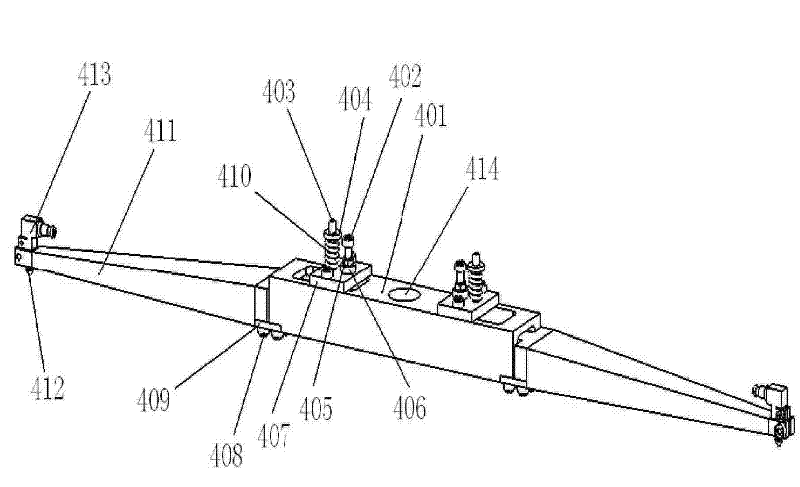

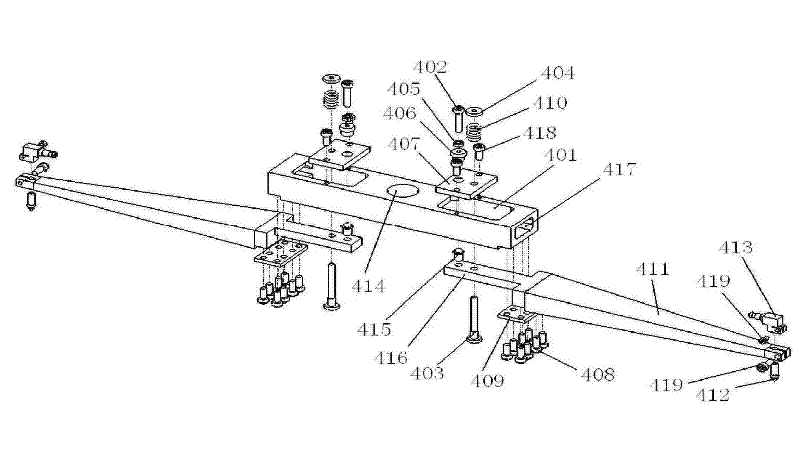

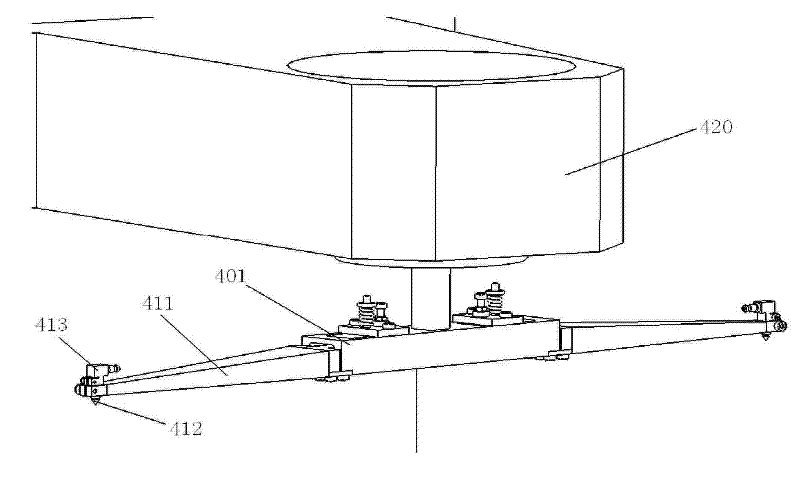

[0012] Below in conjunction with accompanying drawing, the utility model feature and extremely relevant feature are further described:

[0013] See attached Figure 1~5 As shown, the numbers in the figure are as follows: 401--rear arm, 402--rear arm electrode screw, 403--pressure adjustment rod, 404--pressure adjustment nut, 405--electrode screw nut, 406--insulation ring, 407 --support plate, 408--elastic sheet fixing screw, 409--elastic sheet, 410--spring, 411--forearm, 412--vacuum nozzle, 413--vacuum nozzle connector, 414--rear arm installation Hole, 415--forearm electrode, 416--extension of forearm rear part, 417--rear arm front end hollow, 418--support plate screw, 419--screw, 420--frame.

[0014] A kind of mechanical arm of the present invention is to install a mechanical arm mechanism on the frame 420 of the grain sorting machine or the solid crystal machine, and this kind of mechanical arm consists of a rear arm 401, a support plate 407, an insulating ring 406, and a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com