Broken yarn detecting circuit for yarn feeder

A yarn break detection and yarn feeder technology, which is applied in textiles, papermaking, knitting, etc., can solve the problems of affecting normal work, not designing isolation circuits, and increasing costs, so as to ensure work reliability, avoid poor contact, and prevent errors. downtime effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

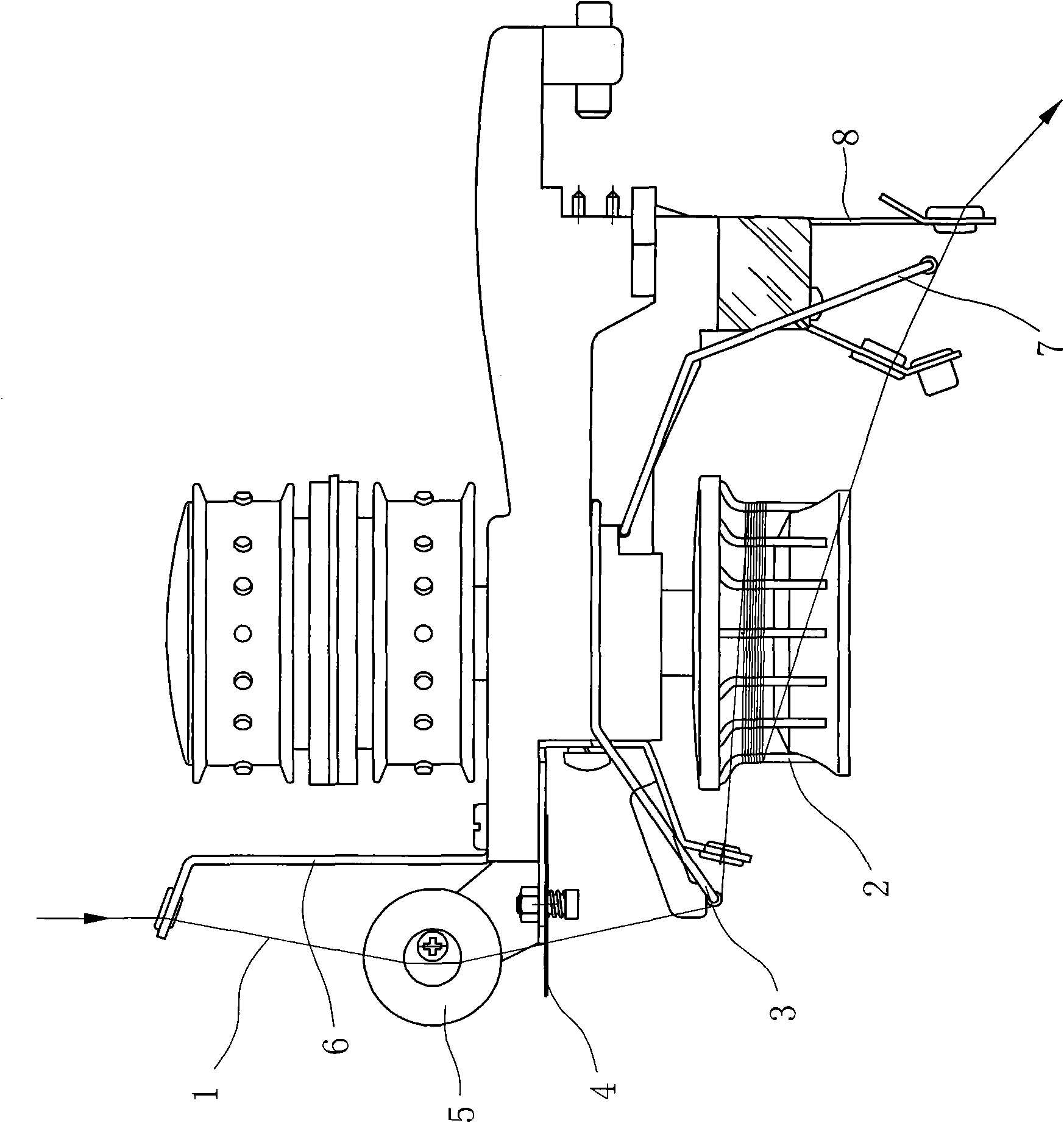

[0037] Embodiment one, such as Figure 5 Shown:

[0038] The slot-type first optocoupler IC1 whose model is ITR8105 is connected in series as the non-contact inductive switch of the present invention in the adopting circuit A. The sampling circuit A takes the first optocoupler IC1 as the core and also includes a first resistor R1, a second Resistor R2;

[0039] Isolation circuit B includes a slot-type second optocoupler IC2 with a model number of P521;

[0040] The signal driving circuit C includes a third resistor R3, a fourth resistor R4, a fifth resistor R5, a first triode Q1, a first capacitor C1 (delay function) and a first light emitting diode D1;

[0041] The front broken yarn detection circuit includes a second rectifier bridge T2 of the same type as MB6F1A, a front broken yarn switch K, a thirteenth resistor R13 and a second light emitting diode D2.

[0042] Wherein, the anode of the light-emitting diode of the first optocoupler IC1 is connected to the anode of the...

Embodiment 2

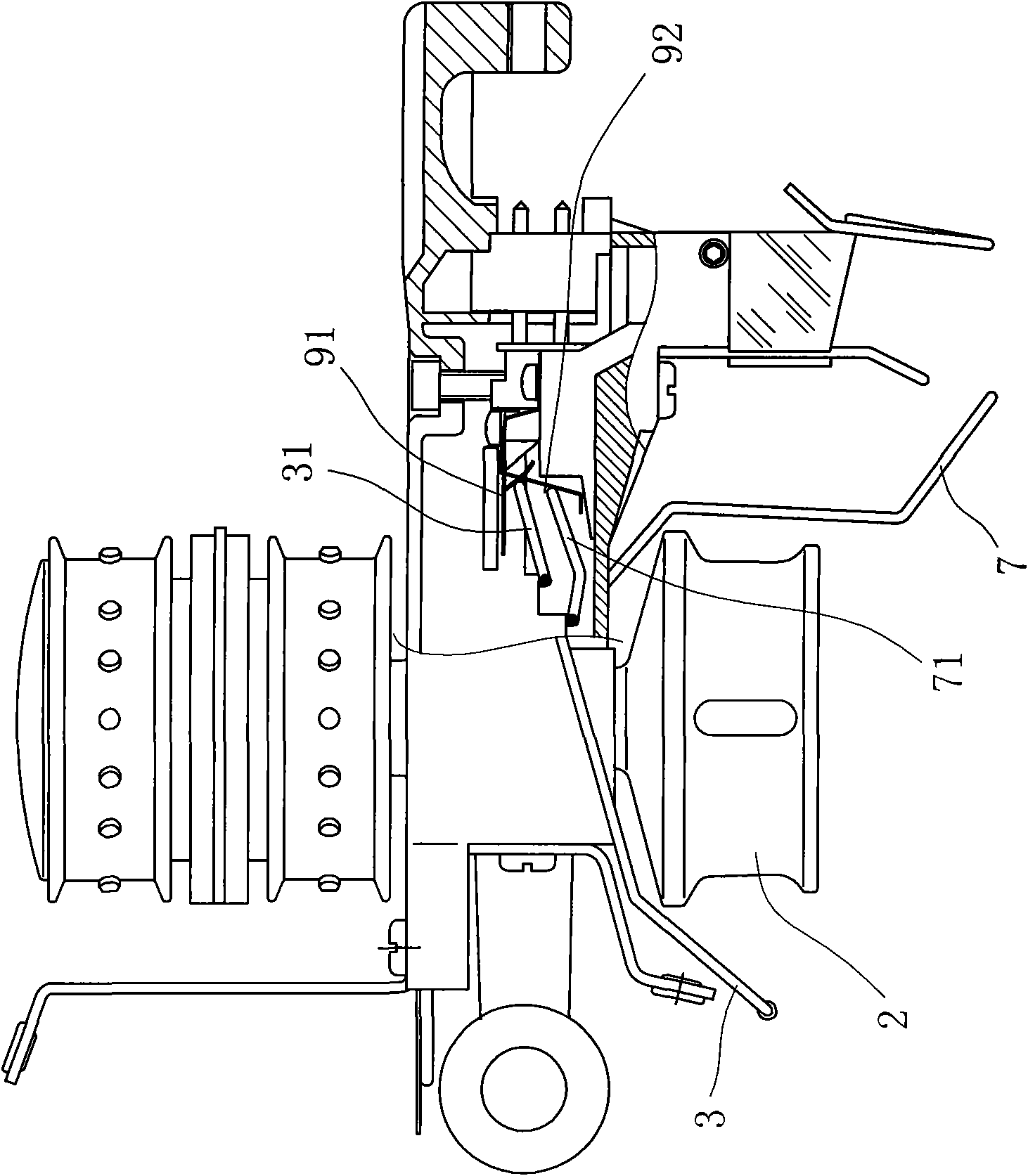

[0050] Embodiment two, such as Figure 6 Shown:

[0051] The component composition of the circuit of this embodiment is the same as that of the first embodiment, the only difference is that the connection mode of the output end of the first optocoupler IC1 and the input end of the second optocoupler IC2 is different.

[0052] In this embodiment, the anode of the light-emitting diode of the first optocoupler IC1 is connected to the anode VCC of the 12V DC power supply through the first resistor R1, and the cathode of the light-emitting diode of the first optocoupler IC1 serves as the first output terminal ao1 and the first The second AC input terminal AC2 of the rectifier bridge T1 is connected, and the triode emitter of the first optocoupler IC1 is connected to the second AC input terminal AC2 of the first rectifier bridge T1;

[0053] The anode of the light-emitting diode of the second optocoupler IC2 is connected to the anode of the DC power supply VCC through the second re...

Embodiment 3

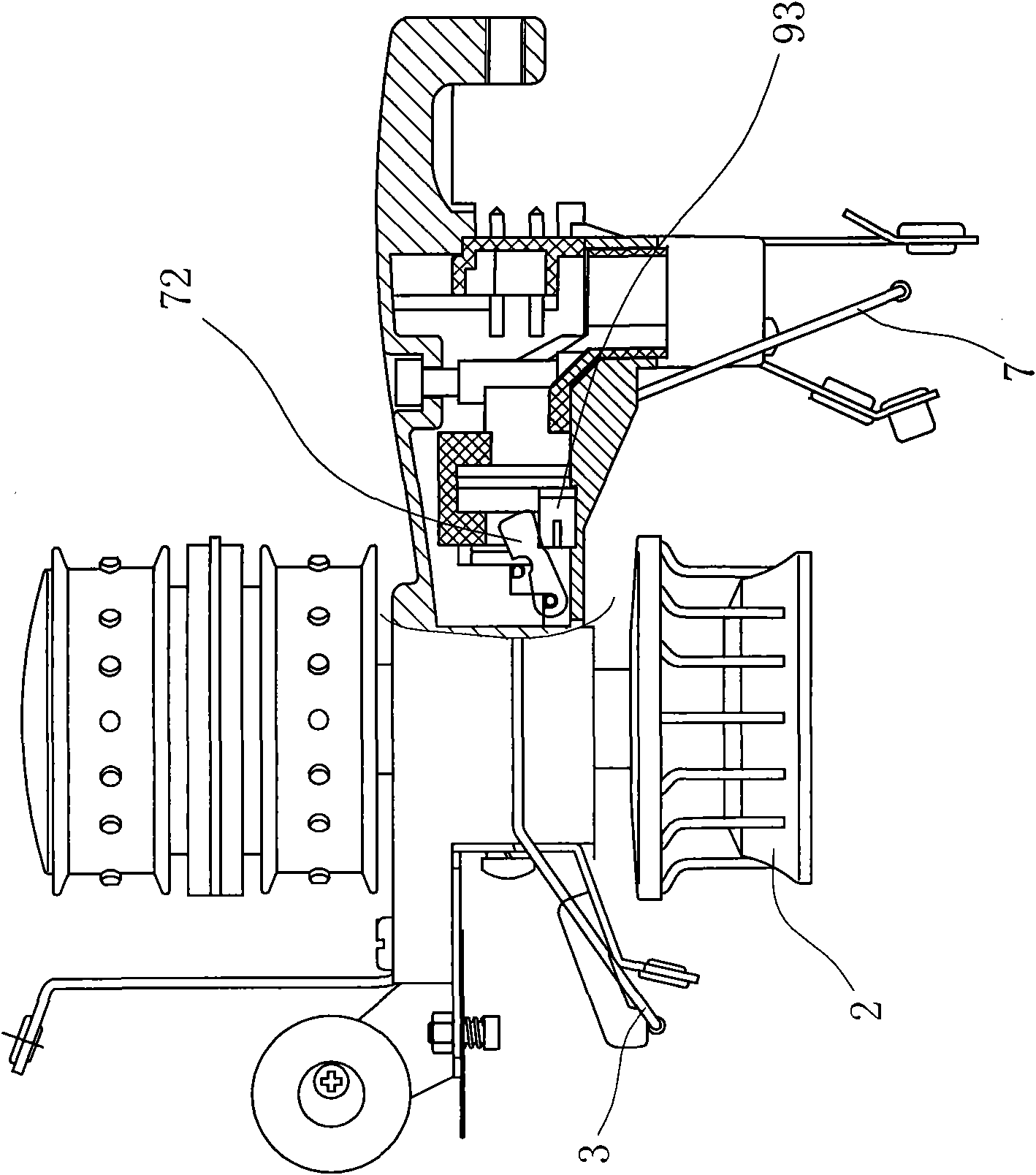

[0058] Embodiment three, such as Figure 7 Shown:

[0059] The slot-type first optocoupler IC1 of the model ITR8105 is connected in series as the non-contact inductive switch of the present invention in the adopting circuit A. The sampling circuit A takes the first optocoupler IC1 as the core and also includes a sixth resistor R6, The seventh resistor R7, the eighth resistor R8 and the second NPN transistor Q2;

[0060] Isolation circuit B includes a slot-type second optocoupler IC2 with a model number of P521;

[0061] The signal drive circuit C includes a ninth resistor R9, a tenth resistor R10, an eleventh resistor R11, a twelfth resistor R12, a first light emitting diode D1, an NPN type third triode Q3 and a second capacitor C2 (time delay effect);

[0062] The front broken yarn detection circuit includes a second rectifier bridge T2 of the same type as MB6F1A, a front broken yarn switch K, a thirteenth resistor R13 and a second light emitting diode D2.

[0063] Wherei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com